Silicon carbide VDMOS device and manufacturing method thereof

A technology of silicon carbide and silicon carbide regions, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of large forward voltage drop, unfavorable promotion of silicon carbide VDMOS devices, and rising system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

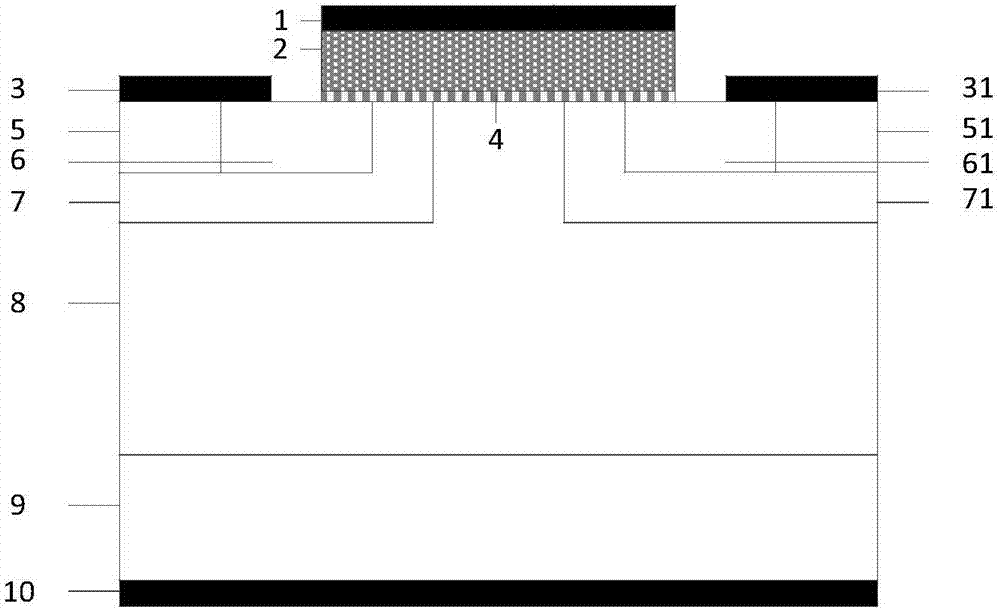

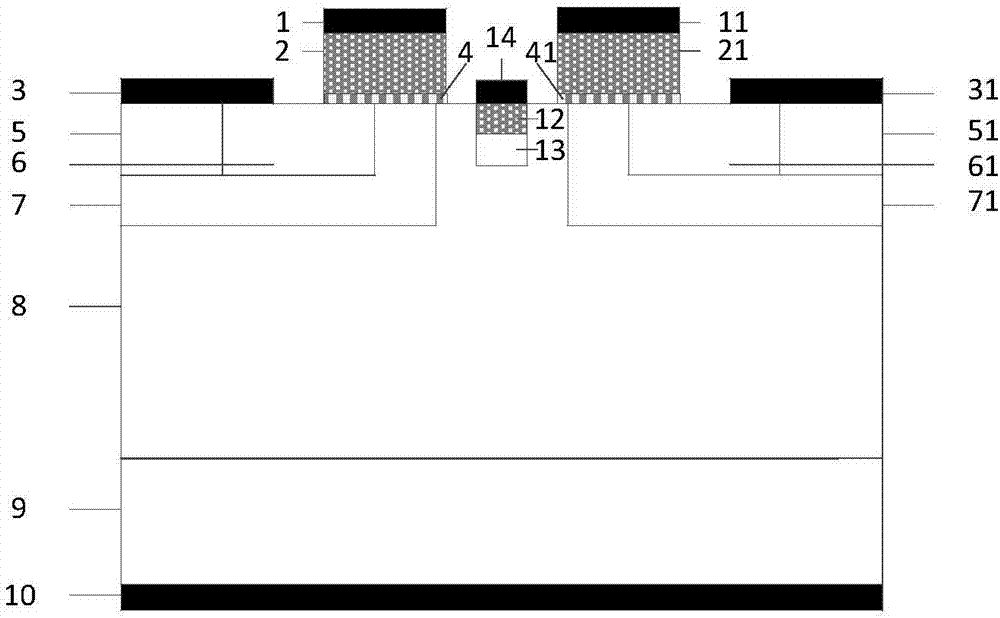

[0104] A kind of silicon carbide VDMOS device provided by the present invention, the cell structure of its basic structure is as follows figure 2 shown. It includes a metal drain electrode 10 arranged sequentially from bottom to top with a thickness of about 0.5-6 μm and a doping concentration of 1×10 18 cm -3 ~1×10 19 cm -3 , N with a thickness of 50-200 μm + The substrate 9 has a thickness of 15-18 μm and a doping concentration of about 1×10 15 cm -3 ~5×10 16 cm -3 N - Epitaxial layer 8; above the N- epitaxial layer 8 has a doping concentration of 1×10 17 ~7×10 17 cm -3 1. Implant the first Pbase region 7 with a depth of about 0.5-1 μm, and the other end of the upper layer has a second Pbase region 71 with the same parameters; the first Pbase region 7 has mutually independent doping concentrations of 1×10 19 ~1×10 20 cm -3 , implanting the first N with a depth of about 0.3-0.5 μm + The source region 6 and the doping concentration are about 3×10 19 ~1×10 20 c...

Embodiment 2

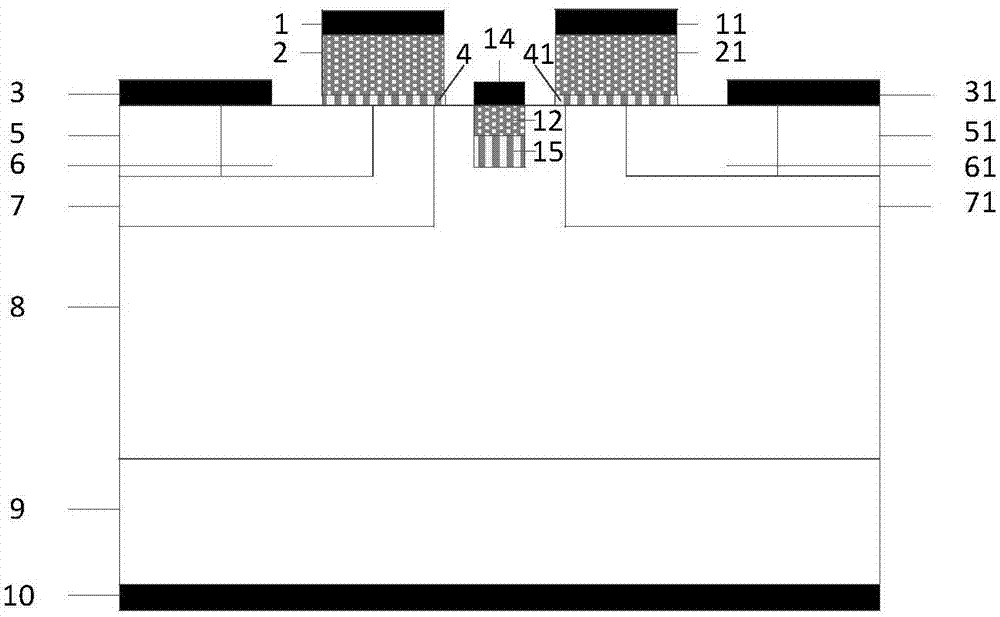

[0106] like image 3 As shown, except that the P-type silicon carbide region 13 is replaced by a dielectric layer 15 with a thickness of 0.02-0.50 μm, the rest of the structure of this embodiment is the same as that of Embodiment 1. Compared with Example 1, the dielectric layer 15 is able to P + The polysilicon layer 12 plays the role of electric field shielding and protection, thereby improving the breakdown voltage and reliability of the device, and reducing the reverse leakage current.

Embodiment 3

[0108] like Figure 4 As shown, except that the width of the P-type silicon carbide region 13 is larger than P + The width of the polysilicon layer 12 and the P-type silicon carbide region 13 in N - Except for the depth inside the epitaxial layer 8 , the rest of the structure of this embodiment is the same as that of Embodiment 1.

[0109] Compared with Embodiment 1, this embodiment further improves the electric field shielding effect of the P-type silicon carbide region 13, further improves the breakdown voltage and reliability of the device, and reduces the reverse leakage current.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com