A kind of preparation method of graphene composite film

A graphene composite and graphene technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of low preparation efficiency, poor mechanical properties and electrochemical properties of graphene films, cumbersome preparation methods, etc., and achieve high toughness and good electrochemical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

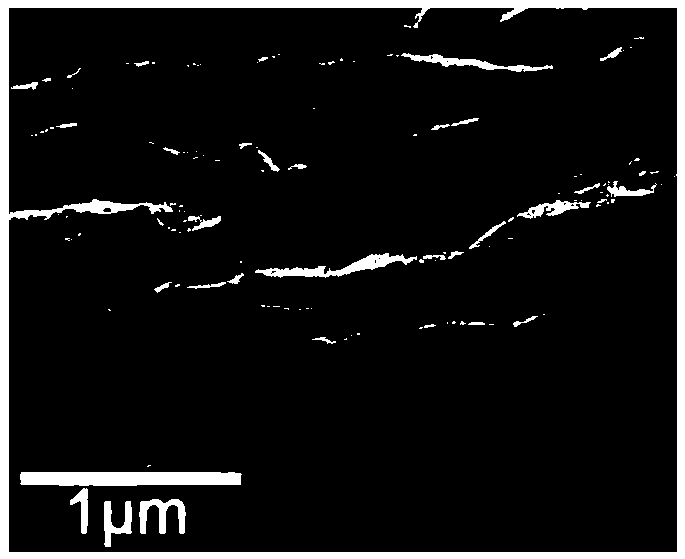

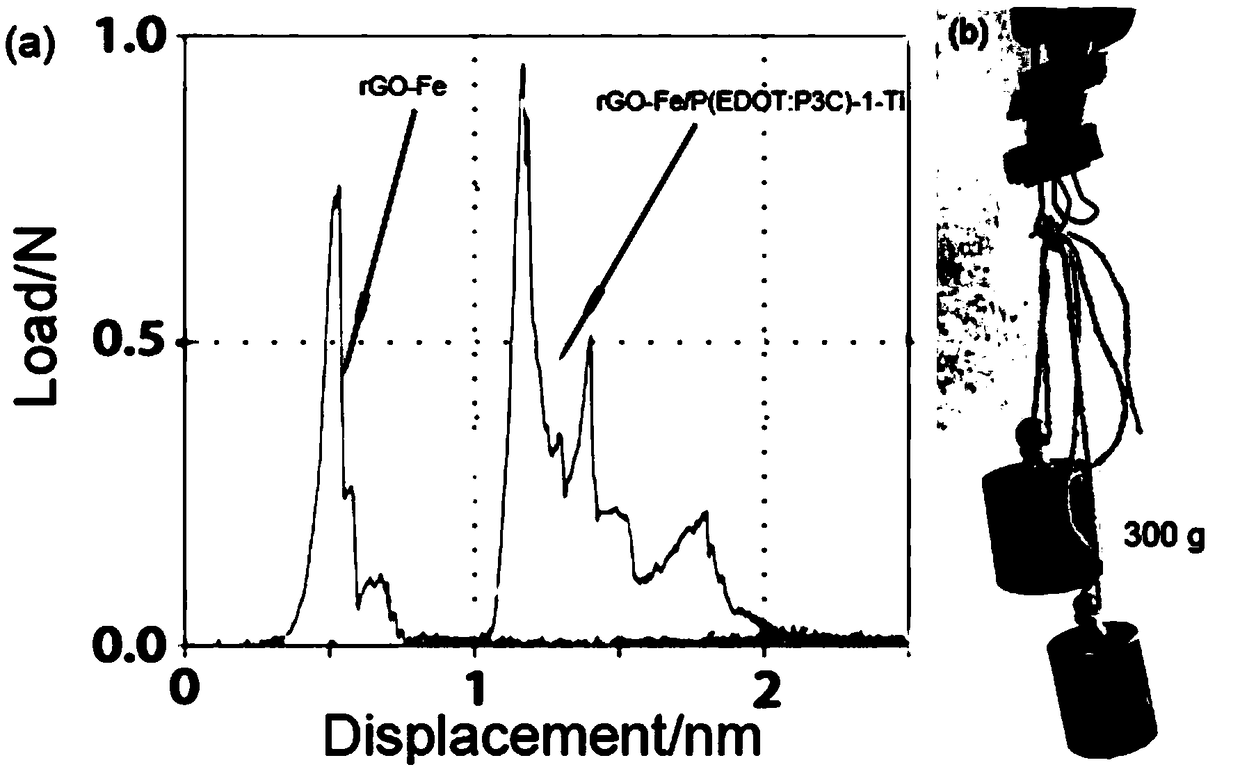

[0035](1) Take the graphene oxide aqueous dispersion prepared by the above method, and adjust the concentration to 8.6 mg / mL. In 2.3mL graphene oxide aqueous dispersion, add 3mg FeCl 3 , shake to form graphene oxide hydrogel. Then use a scraper with a height of 520 μm to scrape the graphene oxide hydrogel on the glass substrate through hydrophilic treatment to make it evenly form a film (4 μm), and let it stand for 15 minutes, and the glass substrate coated with graphene oxide film Put it into the mixed solution of hydroiodic acid and HAc with a volume ratio of 1:2, soak it at room temperature for 2 hours, the graphene oxide hydrogel film gradually turns black, and the graphene oxide is reduced. Then the mixture was heated to 75°C and kept at this temperature for 6h. The black reduced graphene oxide film was separated from the glass substrate, and then it was washed repeatedly with deionized water to remove residual HI and other impurities in the material. Finally, the mate...

Embodiment 2

[0040] (1) Take the graphene oxide aqueous dispersion prepared by the above method, and adjust the concentration to 8.6 mg / mL. In 2.3mL graphene oxide aqueous dispersion, add 3mg FeCl 3 , shake to form graphene oxide hydrogel. Then use a scraper with a height of 520 μm to scrape the graphene oxide hydrogel on the glass substrate through hydrophilic treatment to make it evenly form a film (4 μm), and let it stand for 15 minutes, and the glass substrate coated with graphene oxide film Put it into the mixed solution of hydroiodic acid and HAc with a volume ratio of 1:2, soak it at room temperature for 2 hours, the graphene oxide hydrogel film gradually turns black, and the graphene oxide is reduced. Then the mixture was heated to 75°C and kept at this temperature for 6h. The black reduced graphene oxide film was separated from the glass substrate, and then it was washed repeatedly with deionized water to remove residual HI and other impurities in the material. Finally, the mat...

Embodiment 3

[0045] (1) Take the graphene oxide aqueous dispersion prepared by the above method, and adjust the concentration to 8.6 mg / mL. In 2.3mL graphene oxide aqueous dispersion, add 3mg FeCl 3 , shake to form graphene oxide hydrogel. Then use a scraper with a height of 520 μm to scrape the graphene oxide hydrogel on the glass substrate through hydrophilic treatment to make it evenly form a film (4 μm), and let it stand for 15 minutes, and the glass substrate coated with graphene oxide film Put it into the mixed solution of hydroiodic acid and HAc with a volume ratio of 1:2, soak it at room temperature for 2 hours, the graphene oxide hydrogel film gradually turns black, and the graphene oxide is reduced. Then the mixture was heated to 75°C and kept at this temperature for 6h. The black reduced graphene oxide film was separated from the glass substrate, and then it was washed repeatedly with deionized water to remove residual HI and other impurities in the material. Finally, the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com