A kind of hollow pva fiber and its preparation method and application

A fiber and hollow technology, which is applied in the field of hollow PVA fiber and its preparation, can solve the problems of poor use effect, degradable performance, and high temperature resistance, acid and alkali resistance in the field of oil and gas fields, and achieves the promotion of secondary exploitation, increased income, and good adhesion. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of hollow PVA fibers:

[0045] (1) Preparation of spinning stock solution: the degree of polymerization is 1800, the degree of alcoholysis is 99.5 (mol)% PVA and copper sulfate, titanium tetrachloride, boric acid are dissolved in water and made into spinning stock solution, wherein PVA is in the stock solution The mass concentration of copper sulfate is 15%, the mass concentration of copper sulfate relative to PVA is 3.5%, the mass concentration of titanium tetrachloride relative to PVA is 1.0%, and the mass concentration of boric acid relative to PVA is 1.2%, the stock solution is heated up to 105~ 110°C, keep the pressure 0.01-0.15MPa, dissolve for 14-15 hours and enter the spinning process. At this time, take a part of the stock solution and lower the temperature to 50°C to measure its viscosity to be 8000mPa·s.

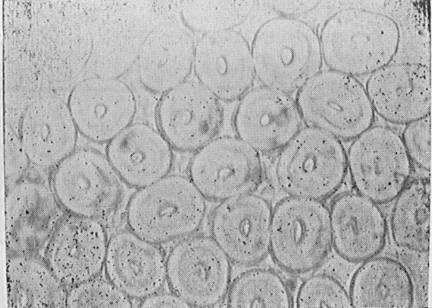

[0046] (2) Spinning: The PVA stock solution is sent to the spinning assembly by a metering pump, and the PVA stock solution is sprayed into th...

Embodiment 2

[0049] Prepare hollow PVA fibers with reference to Example 1, wherein PVA fibers are prepared by spinning polyvinyl alcohol with a degree of polymerization of 2000 and a degree of alcoholysis of 99.5 (mol), the section of the PVA fibers is a hollow structure, and the diameter of the hollow part is 50 μm, the PVA fiber contains copper element, the mass content of copper element in the PVA fiber is 0.08%, and the PVA fiber also contains polyethylene glycol with a molecular weight of 1000.

Embodiment 3

[0051] Prepare hollow PVA fibers with reference to Example 1, wherein PVA fibers are prepared by spinning polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99.0 (mol). The section of the PVA fibers is a hollow structure, and the diameter of the hollow part is 70 μm, the PVA fiber contains copper and titanium elements, the mass content of copper and titanium in the PVA fiber is 1.5%, and the PVA fiber also contains polyethylene glycol with a molecular weight of 1500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com