Full-intelligent water purifying and scale preventing device mounted on pipeline

An intelligent, water-purifying technology, applied in water treatment sites, descaling and water softening, special compound water treatment, etc., can solve problems such as poor safety performance, pollution, etc., so that it is not easy to lose electronics, reduce costs, and improve anti-scaling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

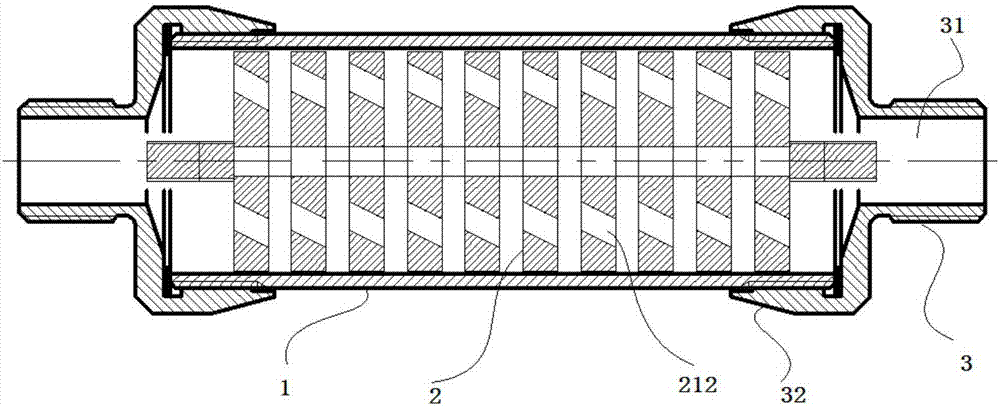

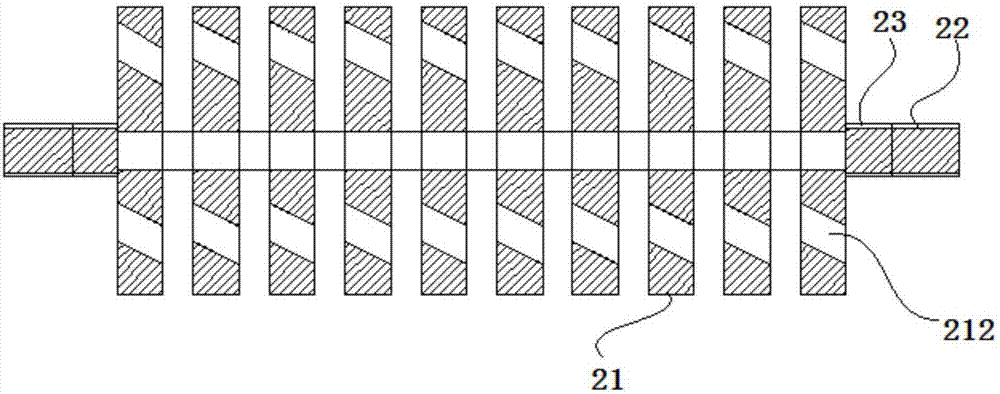

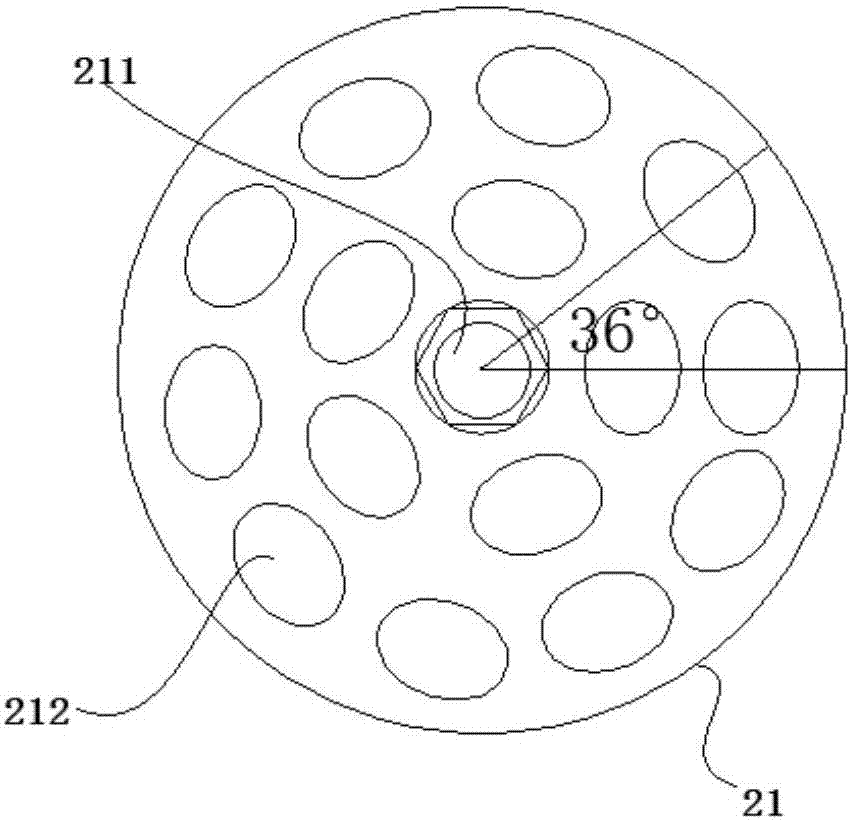

[0024] Such as figure 1 As shown, the all-intelligent water purification and anti-scaling device installed on the pipeline according to the present invention includes an anti-scaling pipe 1, an anti-scaling body 2, and two pipe joints 3, and the anti-scaling body 2 is placed in the anti-scaling pipe 1. The two pipe joints 3 are installed at both ends of the anti-scaling pipe 1 respectively, and the anti-scaling body 2 is fixed in the anti-scaling pipe 1 .

[0025] Both ends of the anti-scaling pipe 1 are opened, and the open end is provided with an external thread, and the pipe joint 3 is screwed on the external thread, and the anti-scaling pipe 1 and the pipe joint 3 are axially sealed by a sealing ring. The pipe joint 3 is hollow, and the middle part is provided with a through hole 31. One end of the pipe joint 3 is installed on the opening end of the anti-scaling pipe 1, and the other end is connected with the pipeline. The pipe joint 3 is provided with a tightening struct...

Embodiment 2

[0030] The difference between this embodiment and Example 1 is that the composition ratio of the fully intelligent anti-scaling and descaling alloy is different. The fully intelligent anti-scaling and descaling alloy in this embodiment includes the following components by mass percentage: Cu: 45%-65%, Ni: 10%-20%, Zn: 10%-20%, Sn: 7%-30%, Ag: 2%-20%, Fe: 2%-8%, Nb: 0.01%-2%, Mn: 0.05%-5%, V: 0.01%-2%, C: 0.01%-0.5%, said components are smelted at high temperature to form a columnar crystal alloy that grows oriented along the S110 crystal axis.

Embodiment 3

[0032] The difference between this embodiment and Example 1 is that the composition ratio of the fully intelligent anti-scaling and descaling alloy is different. The fully intelligent anti-scaling and descaling alloy in this embodiment includes the following components by mass percentage: Cu: 50%-60%, Ni: 12%-18%, Zn: 10%-15%, Sn: 7%-10%, Ag: 2%-8%, Fe: 2%-6%, Nb: 0.01%-2%, Mn: 0.05%-5%, V: 0.01%-2%, C: 0.01%-0.2%, said components are smelted at high temperature to form a columnar crystal alloy that grows oriented along the S110 crystal axis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com