Ni/Fe bimetal-containing MOFs nitrogen-containing graphitized carbon material

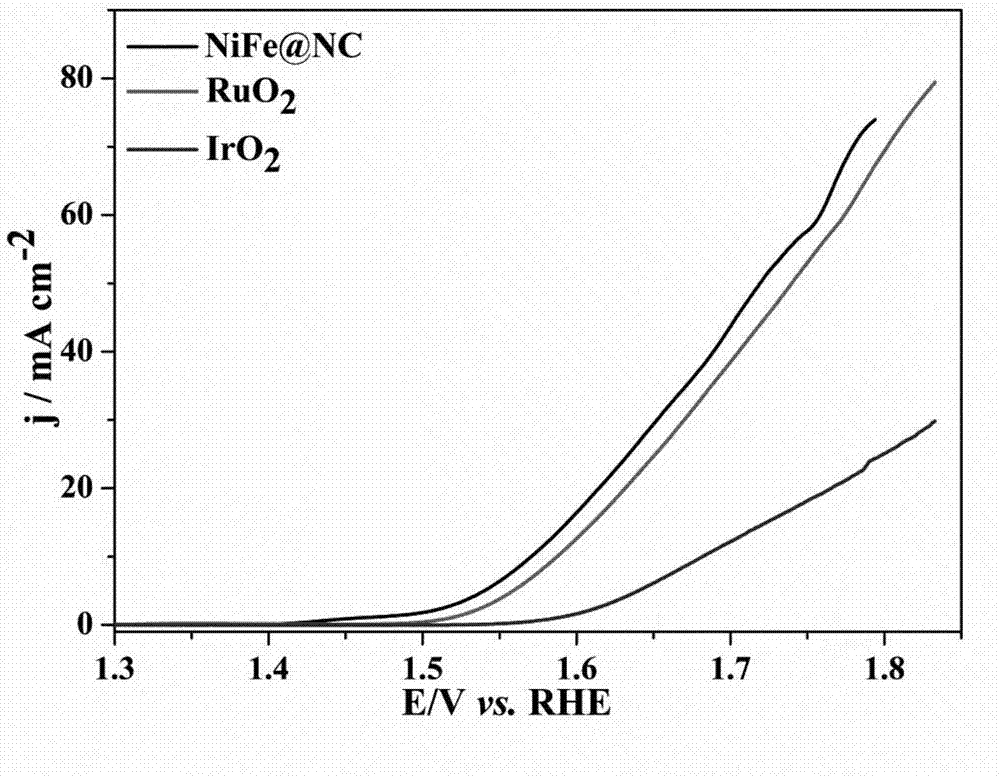

A graphitized carbon and bimetal technology, which is applied in the directions of heat exchange materials, electrode shapes/types, chemical instruments and methods, etc., can solve the problems of expensive precious metals and restrict the promotion and application of catalysts, and achieve high specific surface area and low price. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Weigh 452.9 mg of 2-aminoterephthalic acid, stir and dissolve in 12.5 mL of DMF at room temperature to form a solution. Weigh 337.9 mg FeCl 3 ·6H 2 O and 363.9 mg Ni(NO 3 ) 2 ·6H 2 O was added to the above DMF solution, stirred and dissolved at room temperature. The obtained mixed solution was added into a polytetrafluoroethylene liner, and reacted by solvothermal method for 12 h at 150 °C. After cooling down to room temperature, the mixture was centrifuged at 8000rpm, washed with DMF and ethanol for 2-3 times, vacuum-dried at low temperature, and activated in vacuum at 200°C to obtain the NiFe-BMOFs precursor (that is, the Ni / Fe bimetallic MOFs precursor ).

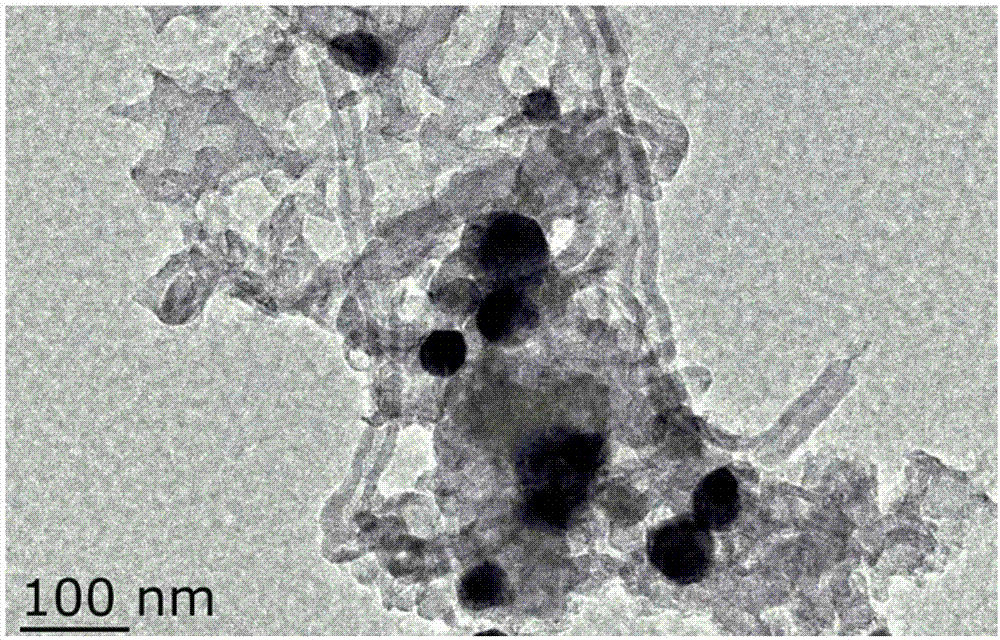

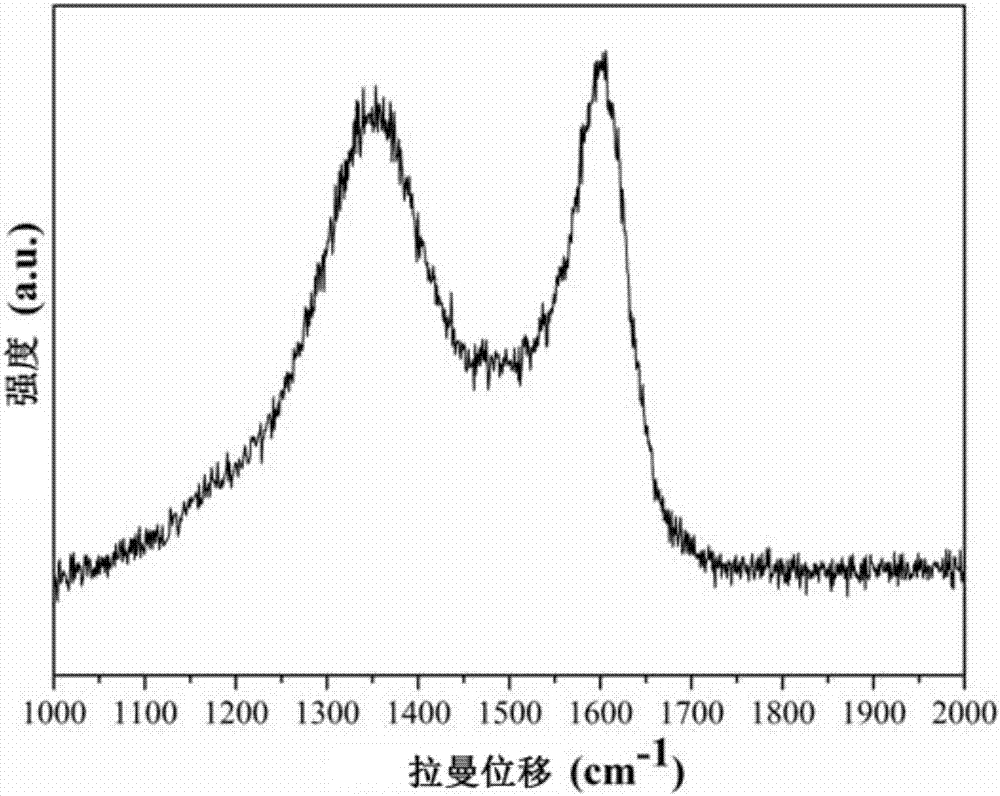

[0028] Step 2: Synthesis of NiFe@NC: Weigh 200 mg of NiFe-BMOFs from step 1 into a tube furnace, 2 In an argon-hydrogen atmosphere with a certain content, the rate was increased to 900 °C at a rate of 5 °C / min, and calcined for 2 h to obtain 43.8 mg NiFe@NC (namely, Ni / Fe bimetallic MOFs nitrogen-co...

Embodiment 2

[0030] Step 1: Weigh 452.9 mg of 2-aminoterephthalic acid, stir and dissolve in 12.5 mL of DMF at room temperature to form a solution. Weigh 135.2 mg FeCl 3 ·6H 2 O and 581.6 mg Ni(NO 3 ) 2 ·6H 2 O was added to the above DMF solution, stirred and dissolved at room temperature. The obtained mixed solution was added into a polytetrafluoroethylene liner, and reacted by solvothermal method for 12 h at 150 °C. After cooling down to room temperature, the mixture was centrifuged at 8000rpm, washed with DMF and ethanol for 2-3 times, vacuum-dried at low temperature, and activated in vacuum at 200°C to obtain the NiFe-BMOFs precursor (that is, the Ni / Fe bimetallic MOFs precursor ).

[0031] Step 2: Synthesis of NiFe@NC: Weigh 200 mg of NiFe-BMOFs from step 1 into a tube furnace, 2 In an argon-hydrogen atmosphere with a certain content, the rate was increased to 900 °C at a rate of 5 °C / min, and calcined for 2 h to obtain 43.8 mg NiFe@NC (namely, Ni / Fe bimetallic MOFs nitrogen-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com