Aqueous organosilicon modified acrylic acid primer-topcoat vehicle axle coating and preparation method thereof

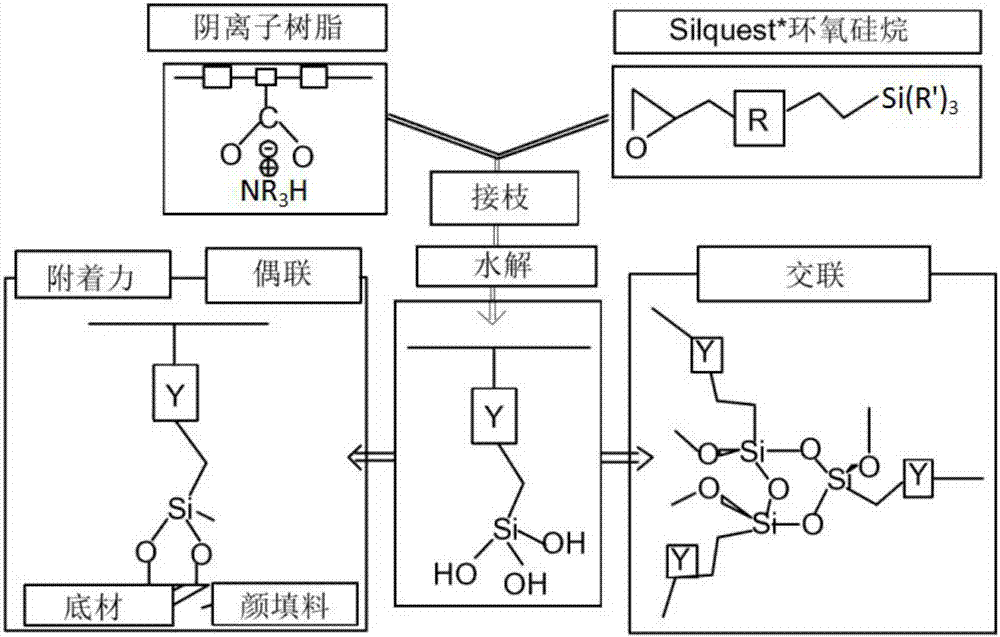

A technology of silicone and acrylic, applied in antifouling/underwater coatings, anti-corrosion coatings, fire-resistant coatings, etc., to achieve the effects of increasing cross-linking degree, improving adhesion, and high hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1-A kind of preparation method of water-based organosilicon-modified acrylic acid bottom and surface integrated vehicle axle paint

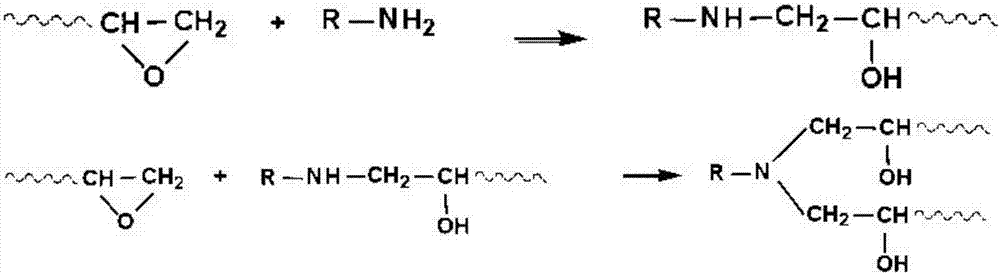

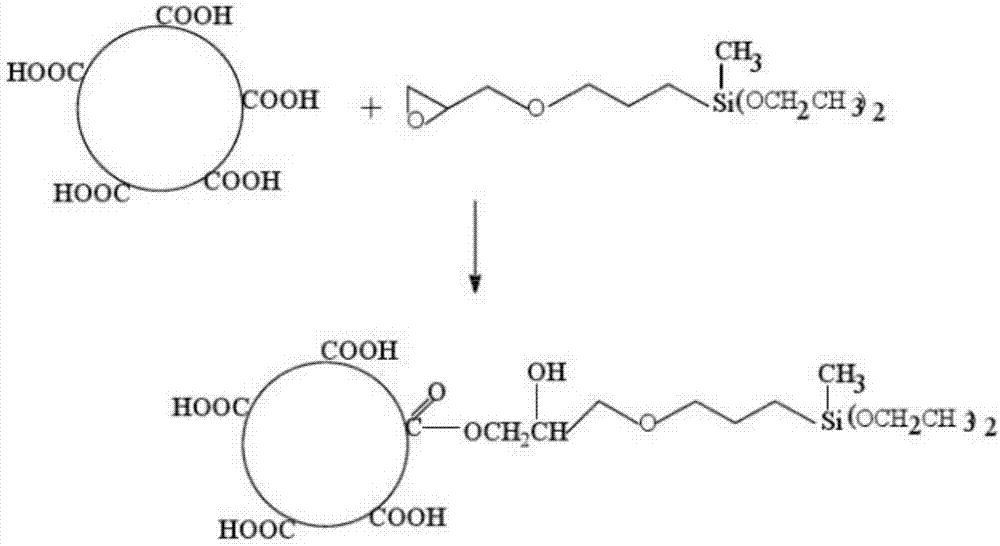

[0037] 1. Silicone modification of acrylic emulsion:

[0038] (1) First, 5 parts of silane coupling agent and 5 parts of deionized water are pre-mixed to make a silane coupling agent mixture;

[0039] (2) Add 100 parts of acrylic emulsion into a stirred reaction kettle with a water bath, set the temperature of the water bath at 40-45°C, and slowly add the silane coupling agent mixture in step (1) to 600- Keep stirring at a speed of 800 rpm for 24 hours to obtain a water-based silicone-modified acrylic emulsion.

[0040] 2. Prepare water-based color paste:

[0041] (1) According to the parts by weight, 35 parts of deionized water are thrown into the container, and 3 parts of ammonia neutralizer, 10 parts of wetting and dispersing agent and 1 part of defoamer are sequentially added while stirring at a speed of 600-800rpm, After...

Embodiment 2

[0052] Embodiment 2-A preparation method of a water-based organosilicon-modified acrylic acid bottom and surface-integrated axle paint, changing the proportion of the chemical components in the water-based color paste, A component and B component, and each raw material is in parts by weight The numbers are as follows:

[0053] Water-based color paste: 25 parts of deionized water, 3 parts of ammonia neutralizer, 10 parts of wetting and dispersing agent, 1 part of defoamer, 20 parts of coloring pigment, 3 parts of special organic corrosion inhibitor, new silicon dioxide anti-rust pigment 12 parts, 10 parts of mica powder, 15 parts of barium sulfate filler and 1 part of anti-sedimentation additive;

[0054] Component A: 15 parts of deionized water, 4 parts of dipropylene glycol methyl ether solvent, 1 part of wetting agent, 0.5 parts of leveling agent, 15 parts of polyamide resin, 60 parts of water-based color paste, 1 part of defoaming aid, water-based 1.5 parts of low-shear th...

Embodiment 3

[0057] Example 3 - A method for preparing a water-based silicone-modified acrylic bottom and surface-in-one axle paint, changing the proportion of the water-based color paste, component A and component B, each raw material in parts by weight The numbers are as follows:

[0058] Water-based color paste: 26 parts of deionized water, 4 parts of ammonia neutralizer, 11 parts of wetting and dispersing agent, 2 parts of defoaming agent, 11 parts of coloring pigment, 4 parts of special organic corrosion inhibitor, new silicon dioxide anti-rust pigment 13 parts, 11 parts of mica powder, 16 parts of barium sulfate filler and 2 parts of anti-sedimentation additive;

[0059] Component A: 18 parts of deionized water, 3 parts of dipropylene glycol methyl ether solvent, 1 part of wetting agent, 0.5 parts of leveling agent, 17 parts of polyamide resin, 57 parts of water-based color paste, 0.5 parts of defoaming aid, water-based 1 part of low-shear thickening aid, 1 part of water-based mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com