Technological method for comprehensive energy consumption recovery in nitrochlorobenzene rectification separation

A technology of nitrochlorobenzene essence and a process method, which is applied in the field of comprehensive energy consumption recovery, can solve the problems of no recovery of condensed water waste heat, no recovery of a rectifying tower, environmental pollution, etc., so as to save water resources and electric energy, and avoid thermal energy loss. , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

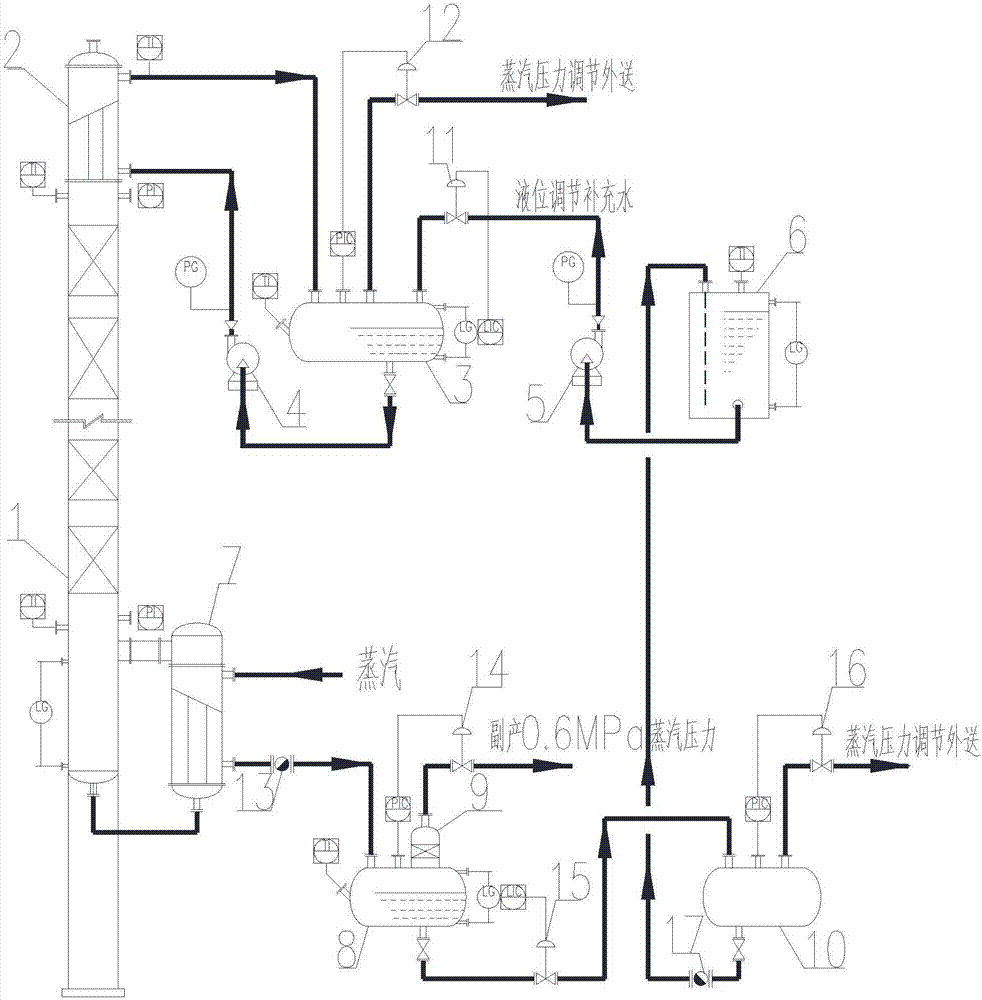

[0032] A process for recovery of comprehensive energy consumption in the rectification and separation of nitrochlorobenzene, comprising two parts, the first part is the heat recovery of the tower top condenser 2, and the second part is the heat recovery of the condensed water of the rectification column reboiler 7 ,

[0033] The first part is specifically: the vapor phase nitrochlorobenzene at the top of the rectifying tower 1 enters the tube side of the tower top condenser 2, and the shell side uses hot water as a circulating cooling medium, and passes through the tube side of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com