Powder containing core particles coated with polymer containing metals, metal oxides, metal nitrides or half metal nitrides

A core particle and polymer technology, which is used in polyamide coatings, metal processing equipment, dyeing polymer organic compounds, etc., can solve problems such as deviations in component performance that are difficult to control, achieve constant improvement in mechanical properties, and reduce static electricity. , the effect of improving recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Example 1: Reprecipitation of nylon 12 (PA 12) (not according to the invention)

[0097] 400 kg of disordered PA 12 prepared by hydrolytic polymerization and having a relative solution viscosity of 1.62 and a COOH end group content of 75 mmol / kg and a NH2 end group content of 69 mmol / kg were denatured with 2-butanone and a water content of 1%. 2500 l of ethanol together in 3 m 3 A stirred tank (a = 160 cm) was heated to 145° C. over a period of 5 hours and maintained at said temperature under stirring for 1 hour (paddle stirrer, x = 80 cm, speed = 49 rpm). The jacket temperature was then lowered to 124° C. and the internal temperature was brought to 125° C. with a cooling rate of 25 K / h at the same stirrer speed with continuous ethanol removal by distillation. From this point onwards, the jacket temperature was kept 2K-3K lower than the internal temperature with the same cooling rate. The internal temperature was brought to 117° C. with the same cooling rate and then ...

Embodiment 2

[0100] Example 2: Single stage reprecipitation of PA12 with core particles (according to the invention)

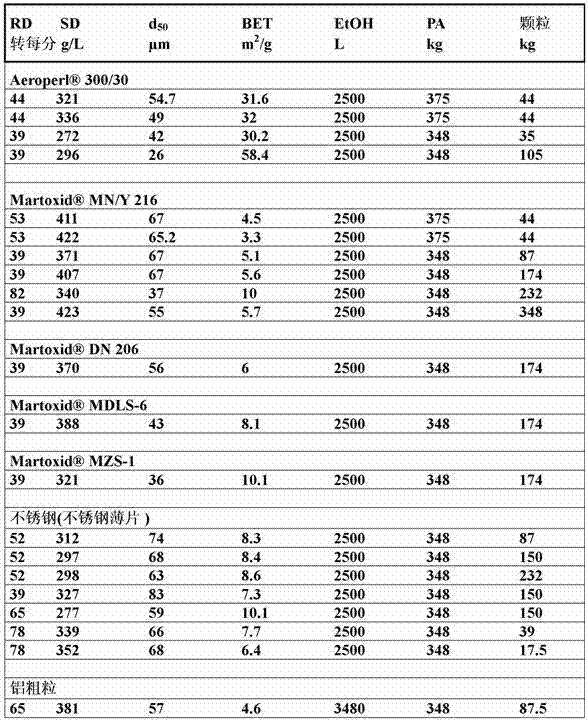

[0101] Corresponding to Example 1, the relative solution viscosity (η rel ) and COOH end group content of 75 mmol / kg and NH of 66 mmol / kg 2 The PA 12 with end group content was reprecipitated in the presence of core particles with the properties given in Table 1:

[0102] Table 1: Characterization data for various core particles used in Example 2:

[0103] particles

d 50

Al 2 o 3 (Martoxid® MN / Y 216)

> 10 µm

al 2 o 3 (Martoxid® DN 206)

5-7 µm

al 2 o 3 (Martoxid® MDLS-6)

3-4 µm

Al 2 o 3 (Martoxid® MZS-1)

1.5-1.9 µm

stainless steel sheet

31 µm

AS081 aluminum powder

28 µm。

[0104] In this example, the precipitation conditions were changed in the following way compared to Example 1:

[0105] Precipitation temperature: 108°C

[0106] Settling time: 150 min

[0107] Stirrer sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com