High-efficiency circulating water treatment agent and application thereof

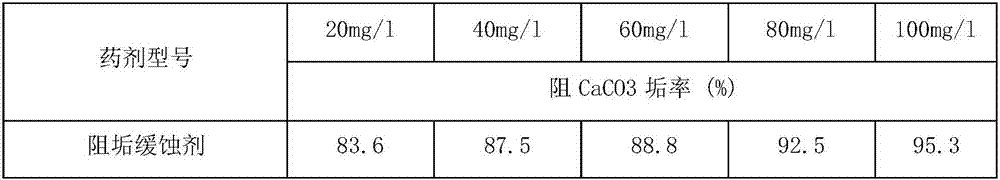

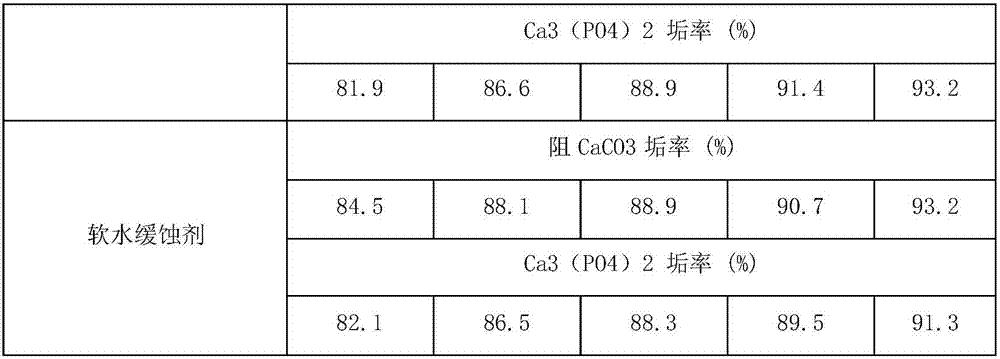

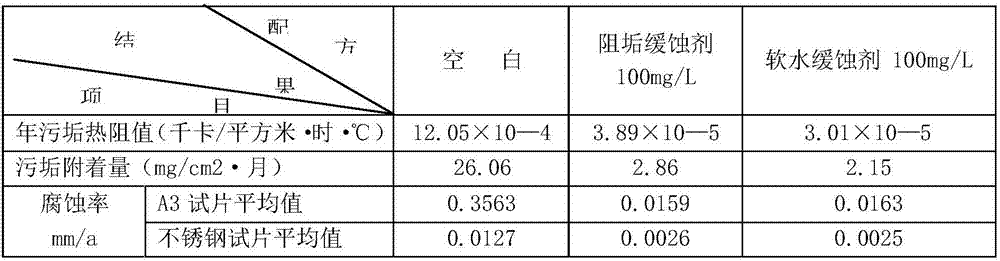

A technology for treating chemicals and circulating water, which is applied in the chemical industry. It can solve the problems of scale formation and corrosion sludge in production equipment, high phosphorus content in water treatment chemicals, and ineffective effects, etc., to achieve excellent dispersion and improve natural degradation ability. , Reduce the effect of sludge adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation of efficient circulating water treatment agent:

[0028] Scale and corrosion inhibitor preparation: by weight percentage, 2% sulfonic acid, 1% hydroxyethylidene diphosphonic acid disodium (HEDP Na2), 12% hydroxyethylidene diphosphonic acid (HEDP), 0.5% polyacrylic acid (PAA), 3% succinic acid and water are uniformly dissolved and mixed, and the sum of the mass percentages of each component is 100%.

[0029] Preparation of soft water corrosion inhibitor: 1% polyacrylic acid (PAA), 4% sodium chloride (NaCl), 2% sodium phosphonobutane tricarboxylate (PBTCA), 1% hydroxyethylidene diphosphonic acid (HEDP) and It is prepared by dissolving in water and mixing uniformly, and the sum of the mass percentages of each component is 100%.

[0030] Preparation of bactericide and algicide: by 4% ZnSO 4 , 8% aminotrimethylene phosphonic acid (ATMP·4Na), 1% polyacrylic acid (PAA), 3% succinic acid and water are uniformly dissolved and mixed, and the sum of...

Embodiment 2

[0031] Embodiment 2: the preparation of efficient circulating water treatment agent:

[0032] Scale and corrosion inhibitor preparation: by mass percentage, by 3% sulfonic acid, 3% hydroxyethylidene diphosphonic acid disodium (HEDP Na2), 16% hydroxyethylidene diphosphonic acid (HEDP), 1.3% polyacrylic acid (PAA), 9% succinic acid and water are dissolved and mixed, and the sum of the mass percentages of each component is 100%;

[0033] Soft water corrosion inhibitor preparation, by mass percentage, by 3% polyacrylic acid (PAA), 6% sodium chloride (NaCl), 6% sodium phosphonobutane tricarboxylate (PBTCA), 3% hydroxy ethylidene diphosphine Made by dissolving and mixing acid (HEDP) and water, the sum of the mass percentages of each component is 100%;

[0034] Preparation of bactericide and algicide: by mass percentage, by 8% ZnSO 4 , 12% aminotrimethylene phosphonic acid (ATMP·4Na), 1% polyacrylic acid (PAA), 9% succinic acid and water are dissolved and mixed, and the sum of the ...

Embodiment 3

[0035] Embodiment 3: the preparation of efficient circulating water treatment agent:

[0036] Preparation of scale and corrosion inhibitor: by mass percentage, by 4% sulfonic acid, 5% hydroxyethylidene diphosphonic acid disodium (HEDP Na ), 31% hydroxyethylidene diphosphonic acid HEDP, 2% polyacrylic acid ( PAA), 5% succinic acid and water are dissolved and mixed, and the sum of the mass percentages of each component is 100%;

[0037] Preparation of soft water corrosion inhibitor: by mass percentage, by 5% polyacrylic acid (PAA), 8% sodium chloride (NaCl), 10% sodium phosphonobutane tricarboxylate (PBTCA), 6% hydroxyethylidene bis Prepared by dissolving and mixing phosphonic acid (HEDP) and water, the sum of the mass percentages of each component is 100%;

[0038] Preparation of bactericide and algicide: by 12% ZnSO 4 , 16% aminotrimethylene phosphonic acid (ATMP·4Na), 2% polyacrylic acid (PAA), 15% succinic acid and water are dissolved and mixed, and the sum of the mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com