Punching machine

A technology of punch presses and crankshafts, applied in the field of mechanical processing equipment, can solve problems such as insufficient precision, unstable operation of punch presses, and high noise, and achieve the effects of avoiding displacement, compact structure, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

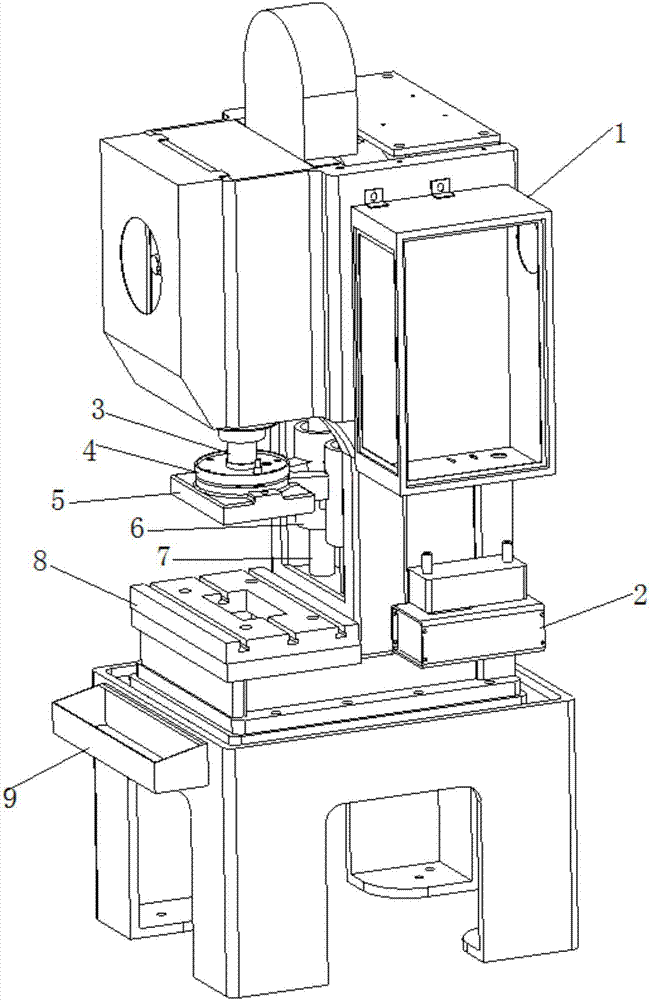

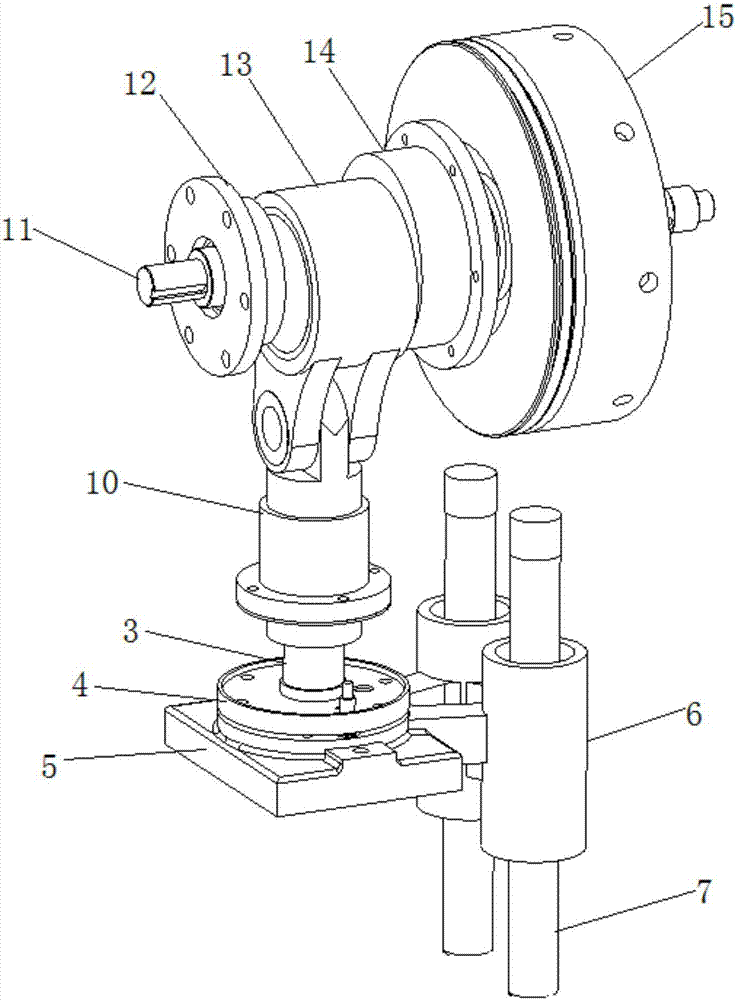

[0012] Such as figure 1 with figure 2 As shown, the present invention provides a kind of punch press, comprises fuselage, workbench 8, electric control box 1, operation box 9, is provided with crank linkage mechanism in described fuselage, and described crank linkage mechanism includes crankshaft 11 and Flywheel 15, crankshaft rear seat 14, connecting rod 13 and crankshaft front seat 12 connected to the crankshaft 11 in sequence from the inside to the outside, the lower end of the connecting rod 13 is connected with the central guide column 10 in rotation, so The bottom of the center guide post ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com