Method for microwave rapid synthesis of lead, graphite oxide doped bismuth ferrite and foam nickel composite material and application thereof

A composite material, bismuth ferrite technology, applied in chemical instruments and methods, oxidized water/sewage treatment, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of few applications, poor synthesis effect, composite catalysis The problem of long synthesis time of materials is achieved, and the synthesis method is simple, the synthesis time is shortened, and the synthesis time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

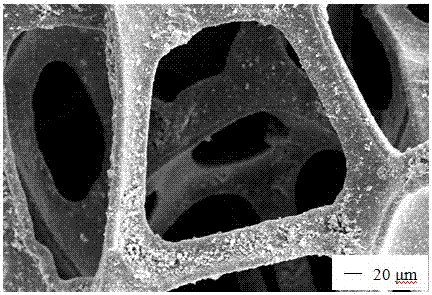

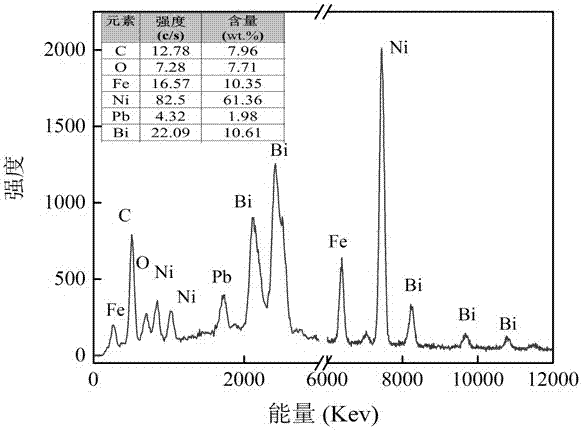

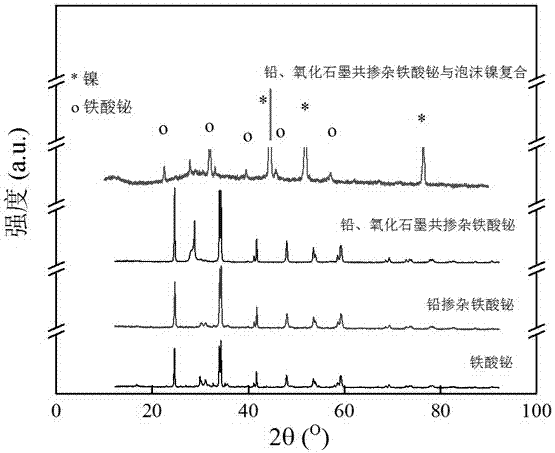

[0029] Specific embodiment one: what this embodiment records is a kind of method for rapid microwave synthesis of lead, graphite oxide doped bismuth ferrite and nickel foam composite material, and the steps of the method are as follows:

[0030] 1. Pretreatment of bismuth ferrite-based composites

[0031] Take 4~5 g ferric nitrate, 4~5 g bismuth nitrate, 0.1~0.3 g lead nitrate, 0.5~1.0 g graphite oxide (powder) and 25~35 mL deionized water or ultrapure water and mix them in a beaker. Ultrasonic treatment at 25-30°C for 15-30 min, then add 3-5 g of sodium hydroxide and continue stirring for 20-30 min, then add 1-2 g of nickel foam, and finally move the mixture to a polytetrafluoroethylene reaction tank to be synthesized;

[0032] 2. Microwave rapid synthesis of pretreated bismuth ferrite-based composites

[0033] Place the polytetrafluoroethylene reaction tank in a microwave oven for microwave-assisted hydrothermal synthesis. After the reaction, take out the polytetrafluoroet...

specific Embodiment approach 2

[0034] Specific embodiment two: the method for rapid microwave synthesis of lead, graphite oxide doped bismuth ferrite and nickel foam composite material described in specific embodiment one, in step two, the microwave reaction temperature is 180 ~ 200 o C, the reaction time is 20-40 min.

specific Embodiment approach 3

[0035] Specific embodiment 3: The microwave rapid synthesis method of lead, graphite oxide doped with bismuth ferrite and nickel foam composite material described in specific embodiment 1, in step 2, the drying temperature is 70~100°C, and the drying time is 2 h .

[0036] Specific embodiment four: the microwave rapid synthesis method of lead described in specific embodiment one, graphite oxide doped bismuth ferrite and nickel foam composite material, in step two, use dehydrated alcohol and deionized water to carry out centrifugal cleaning, centrifugal speed The speed is 3500 rap / min, and the centrifugation time is 5 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com