Method for preparing transparent flexible supercapacitor

A supercapacitor, transparent technology, applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of low energy density and high brittleness of transparent substrate materials, achieve good flexibility, improve high power output performance, and solve the problem of brittleness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

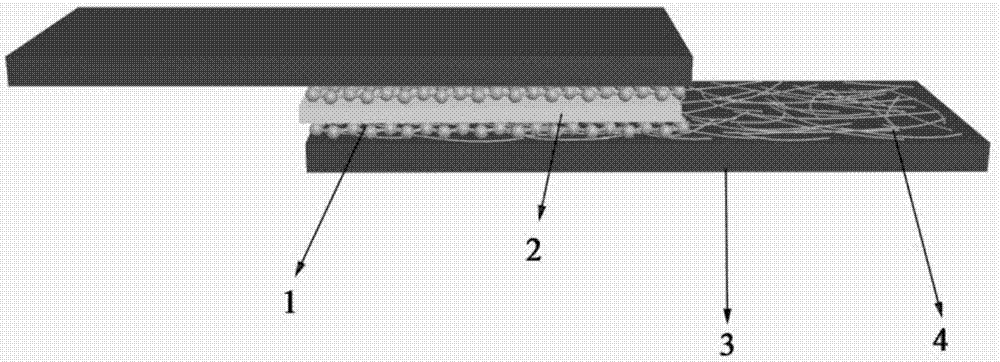

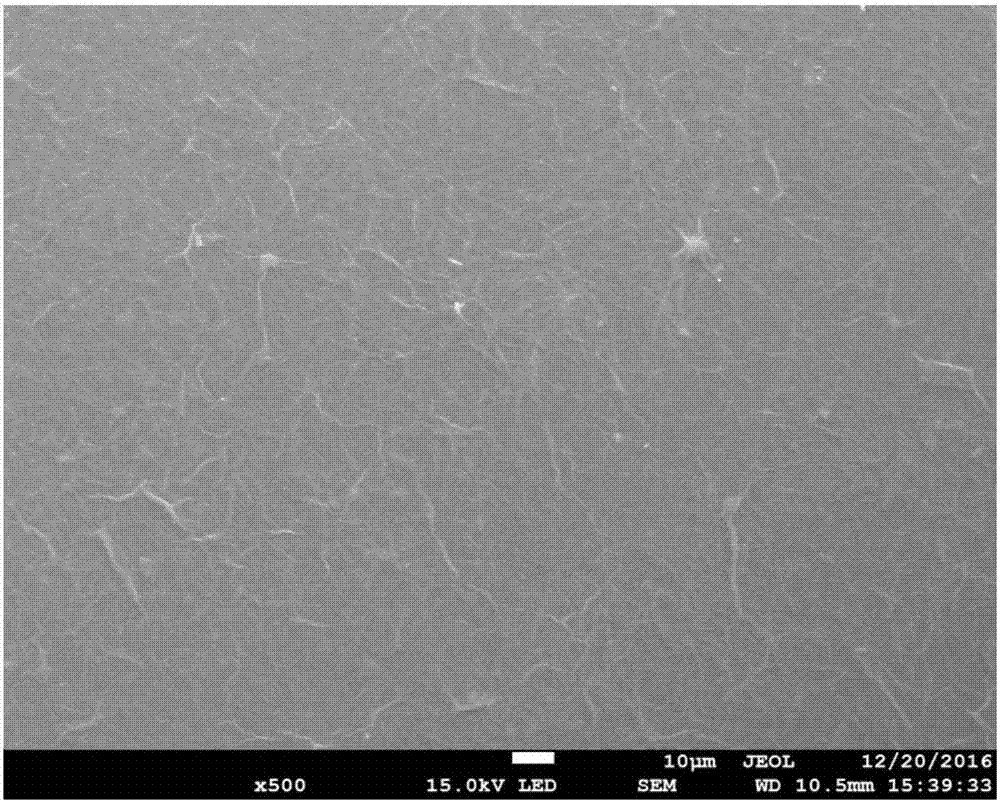

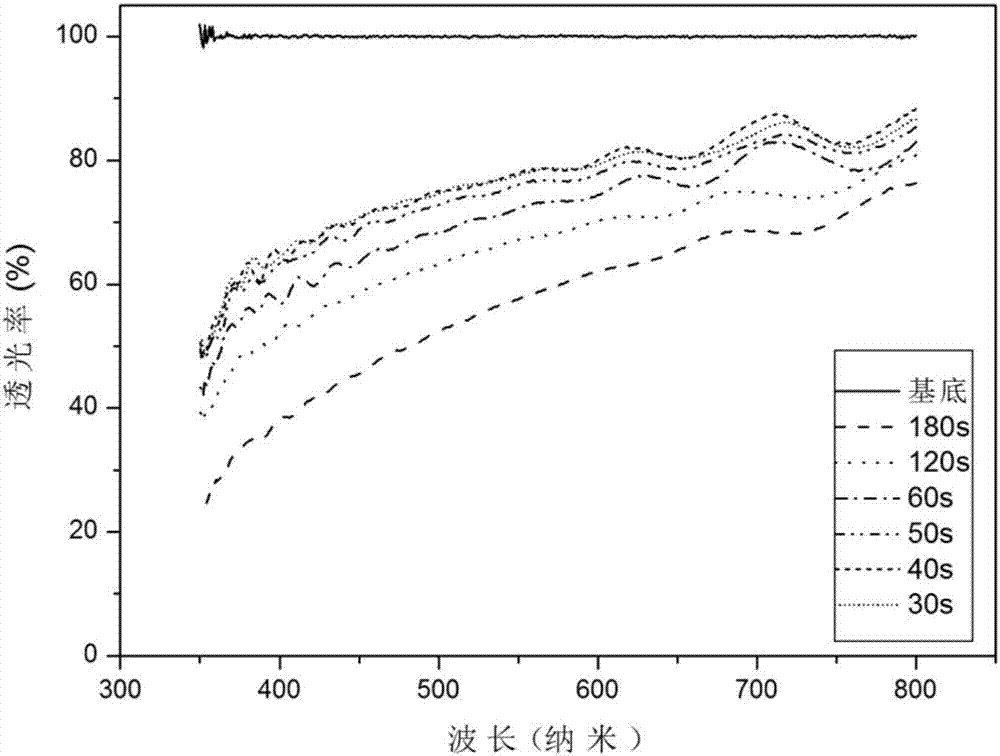

[0034] (1) Spin-coat 0.5mg / ml nano-silver wire solution (10ml) on the surface of a layer of 10cm x 10cm PET substrate with a homogenizer. Heating for 5 minutes under the same conditions, a transparent and flexible current collector whose surface is covered with a network of metal nanowires is prepared, and the thickness of the coating is 100 nm.

[0035] (2) in the graphene of getting 25mg and 40ml mixed solution, (the composition of mixed solution is the concentrated sulfuric acid and the concentrated nitric acid, and the volume ratio is the concentrated sulfuric acid: concentrated nitric acid 3:1; The concentration of the concentrated sulfuric acid is mass fraction 98%, concentrated nitric acid The concentration is 65% of the mass fraction) and mixed, stirred at 70°C for 4h, then the mixed solution was suction filtered, and the solution after suction filtration was subjected to dialysis (that is, the above mixed liquid was poured into a dialysis bag, and then the dialysis bag...

Embodiment 2

[0041] (1) Spin-coat 0.5mg / ml nano-silver wire solution (10ml) on the surface of a layer of 10cm x 10cm PET substrate with a homogenizer. Heating for 5 minutes under the same conditions, a transparent and flexible current collector whose surface is covered with a network of metal nanowires is prepared, and the thickness of the coating is 100 nm.

[0042] (2) in the graphene of getting 25mg and 40ml mixed solution, (the composition of mixed solution is the concentrated sulfuric acid and the concentrated nitric acid, and the volume ratio is the concentrated sulfuric acid: concentrated nitric acid 3:1; The concentration of the concentrated sulfuric acid is mass fraction 98%, concentrated nitric acid The concentration is 65% of the mass fraction) and mixed, stirred at 70°C for 4h, then the mixed solution was suction filtered, and the solution after suction filtration was subjected to dialysis (that is, the above mixed liquid was poured into a dialysis bag, and then the dialysis bag...

Embodiment 3

[0047] (1) Spin-coat 0.5mg / ml nano-silver wire solution (10ml) on the surface of a layer of 10cmx10cm PET substrate with a homogenizer. After heating for 5 minutes, a transparent and flexible current collector whose surface is covered with a network of metal nanowires is prepared, and the thickness of the coating is 100 nm.

[0048] (2) in the graphene of getting 25mg and 40ml mixed solution, (the composition of mixed solution is the concentrated sulfuric acid and the concentrated nitric acid, and the volume ratio is the concentrated sulfuric acid: concentrated nitric acid 3:1; The concentration of the concentrated sulfuric acid is mass fraction 98%, concentrated nitric acid The concentration is 65% of the mass fraction) and mixed, stirred at 70°C for 4h, then the mixed solution was suction filtered, and the solution after suction filtration was subjected to dialysis (that is, the above mixed liquid was poured into a dialysis bag, and then the dialysis bag was immersed in deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com