Experimental device for testing heat exchange properties at low temperature within wide Reynolds number range

A test device and Reynolds number technology, which is used in measurement devices, testing of machine/structural components, instruments, etc., can solve the problems of introducing calculation errors and not having performance experimental data, and achieves reducing thermal balance errors, ensuring safety, and testing accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

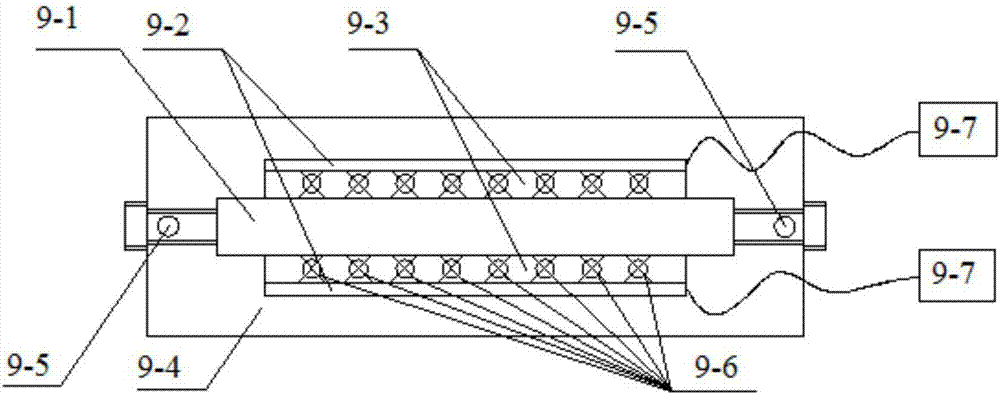

[0022] see figure 1 , 2 , a heat exchanger performance test device for testing large Reynolds number ranges at low temperatures, including a compressor 1, a flow regulation and distribution system, a helium cooling section, a finned core test section, and a measurement and acquisition system. The regulating and distributing system includes a bypass with a throttle valve 2 and two main circuits with bellows regulating valves 3 and 4 in parallel. The two main circuits are respectively connected with mass flow controllers with different measurement ranges. 5, 6;

[0023] The helium cooling and cooling section includes a liquid nitrogen source 13, a liquid nitrogen pipeline connected to the liquid nitrogen source 13, and secondary plate-fin heat exchangers 7 and 8 for sequentially exchanging heat with the liquid nitrogen pipeline. The outlet end of the road is connected with a reheater 15, a flow meter 16 and a regulating valve 17 in sequence;

[0024] The finned core test sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com