Wing type energy dissipating plate and debris flow drainage trough including same

A technology of energy-dissipating plates and row guide grooves, which is applied in construction, artificial waterways, climate change adaptation, etc., can solve problems such as easy wear and difficulty in ensuring the stability of the upper structure, so as to ensure safe use, weaken kinetic energy of movement, and weaken erosion The effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

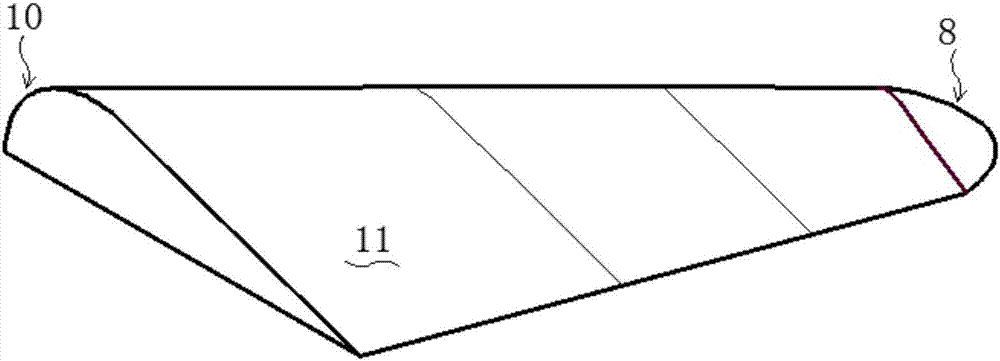

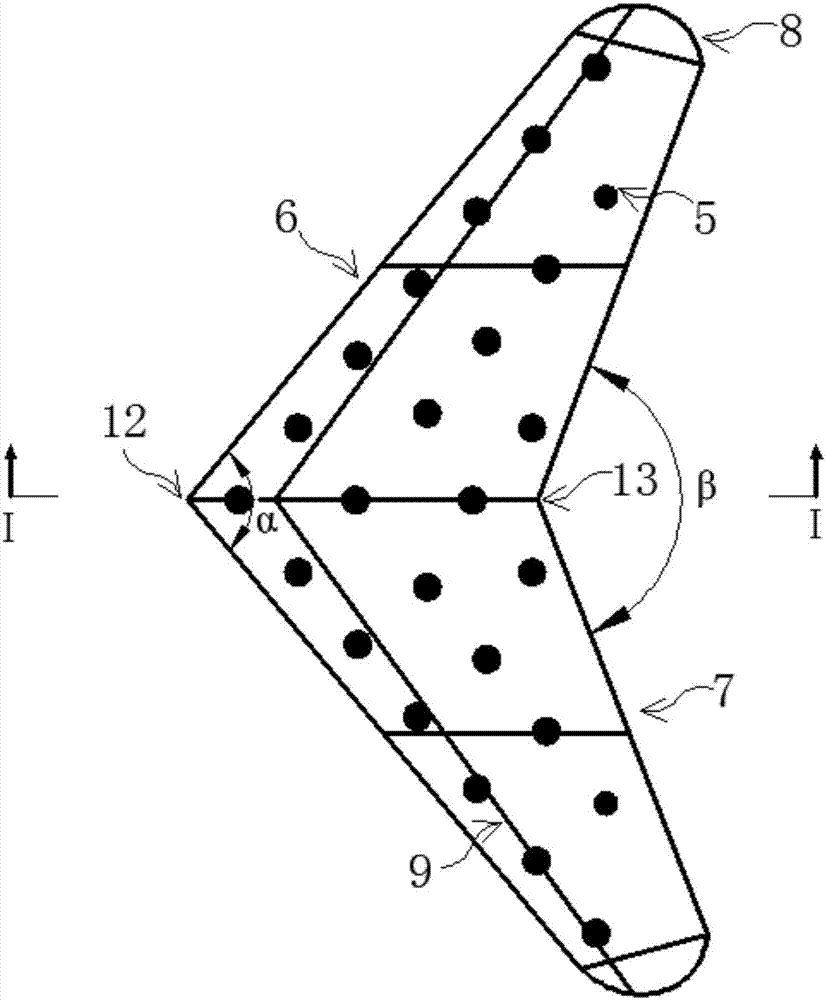

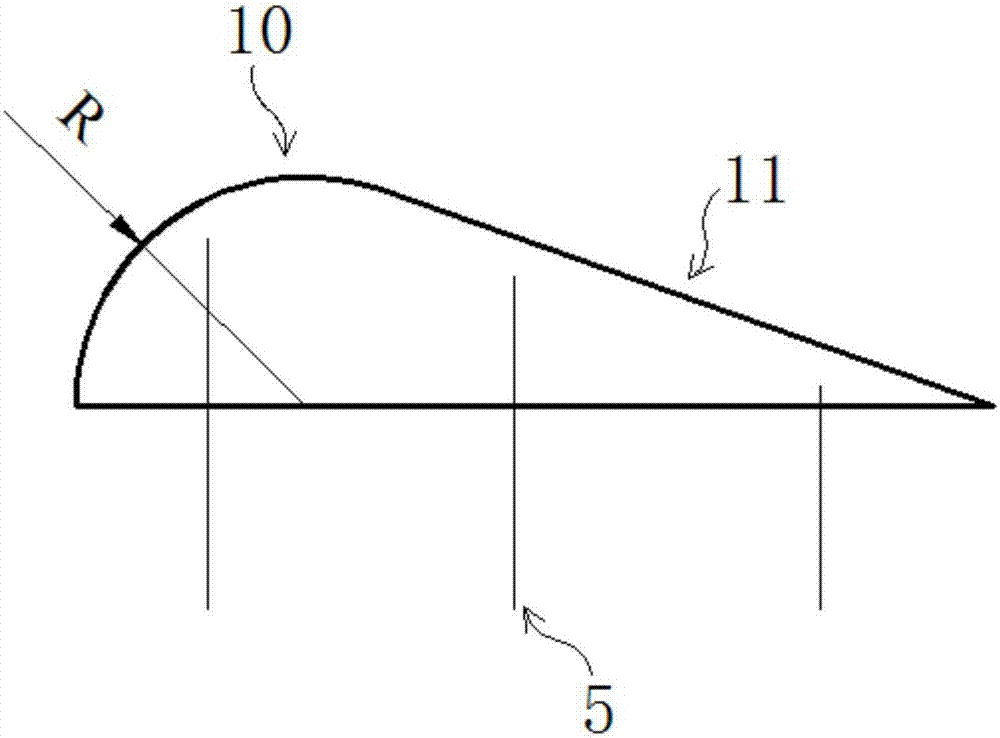

[0036] Such as Figure 1-Figure 10 shown. The drainage area of a debris flow ditch is 20.4km 2 , There have been many mudslides in the channel, threatening downstream villages and farmland. In order to reduce debris flow disasters, the control measures of "blocking + drainage + silting" are adopted. Under the design standard of once in 20 years, the bulk density of debris fluid is 1.8t / m 3 , mainly transitional-viscous debris flow. In order to reduce the scouring damage of debris flow to the bottom of the rapid section of the drainage channel, the drainage measure adopts the energy dissipation and anti-scouring full-lined debris flow drainage channel of the present invention, and the flow rate of the debris flow is designed to be 50.3m 3 / s, the vertical gradient i of the drainage channel is 180‰, the planned total length of the drainage channel is 452m, of which the rapid flow section is 158m long, the bottom width B of the drainage channel is 6m, and the depth H is 5m. ...

Embodiment 2

[0039] Such as Figure 1 to Figure 9 shown. The drainage area of a debris flow ditch is 3.36km 2 , The gully has repeatedly erupted in mudslides, which washed away the bridges at the mouth of the ditch and buried the road. In order to prevent debris flow from impacting bridges and silting roads, the treatment measures of "blocking + drainage + silting" are adopted. Under the design standard of once in 20 years, the bulk density of debris fluid is 2.1t / m 3 , is a viscous debris flow. In order to reduce the scouring damage of the debris flow to the bottom of the rapid section of the drainage channel, the drainage channel adopts the energy dissipation and anti-scouring full-lined debris flow drainage channel of the present invention, and the flow rate of the debris flow is designed to be 162m 3 / s, the vertical gradient i of the drainage channel is 300‰, the planned total length of the drainage channel is 186m, of which the rapid flow section is 61m long, the bottom width B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com