Novel wooden composite board

A composite board and wood technology, which is applied in the joining of wooden veneers, wood laminate products, wood processing appliances, etc. The effect of flame spread, isolation of oxygen, and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

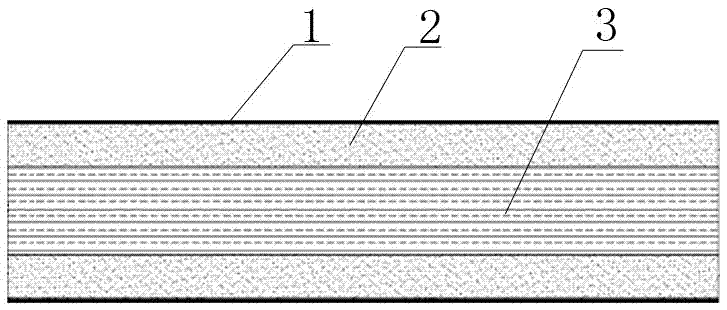

[0032] refer to figure 1 , a new type of wood composite board, which includes a central layer 3; the upper and lower sides of the central layer 3 are respectively provided with a transition layer 2; the upper and lower sides of the transition layer 2 are respectively provided with an impregnated paper layer 1; the impregnated paper layer 1. The transition layer 2 and the central layer 3 are connected by high temperature and high pressure bonding.

[0033] The transition layer 2 is a shaving fiber layer structure; the central layer is a modified wood-plastic board.

[0034] In order to facilitate firm connection, the upper and lower surfaces of the central layer 3 and the transition layer 2 may also be provided with roughened concave-convex layers.

[0035] The production process of the composite board is as follows:

[0036] 1) The raw materials are crushed, polished, dried, and screened to produce qualified shaving fibers for use; the environmentally friendly glue is prepar...

Embodiment 2

[0043] The present invention also relates to the improvement of the central layer, which is a modified wood-plastic board, specifically, prepared according to the following process:

[0044] 1) Weigh the raw materials by weight for later use: 50-70 parts of wood fiber, 7-9 parts of polypropylene resin, 3-5 parts of flame retardant, 3-5 parts of inorganic filler, 2-3 parts of polyvinyl alcohol, curing agent 1-2 parts, glass fiber 0.3-0.5 parts;

[0045] Described flame retardant is mixed by red phosphorus and tributyl phosphate according to the mass ratio of 2:1;

[0046] The inorganic filler is formed by mixing silicon carbide and aluminum oxide at a mass ratio of 1:1;

[0047] The curing agent is prepared according to the following process: put toluene diisocyanate and butyl acetate into the reactor according to the volume ratio of 3:1, heat to 60°C, stir at 200rpm for 30min under the condition of heat preservation, and then add dropwise the mixture with acetic acid Trimeth...

Embodiment 3

[0051] The present invention also detects the effect of the curing agent on the performance of the modified wood-plastic panel:

[0052] The control group selects commonly used polyurethane solidifying agent for use, and all the other are the same as embodiment 2; Each performance parameter is respectively: impact strength 33.6kJ / cm 2 ; thermal conductivity is 0.027W / (m k); water absorption 0.046%; dimensional stability (GB / T8811 "30 ℃, 48 hours") 0.32%. It can be seen that the curing agent of the present invention has reasonable compatibility and can effectively improve the performance of the plate, which is better than the commonly used curing agents in the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com