Shaft-free lubricating oil mixing tank

A lubricating oil and mixing tank technology, applied in mixers, fluid mixers, dissolving and other directions, can solve the problems of poor mixing effect and low mixing efficiency, and achieve the effect of favorable flow, high mixing efficiency and small bottom area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

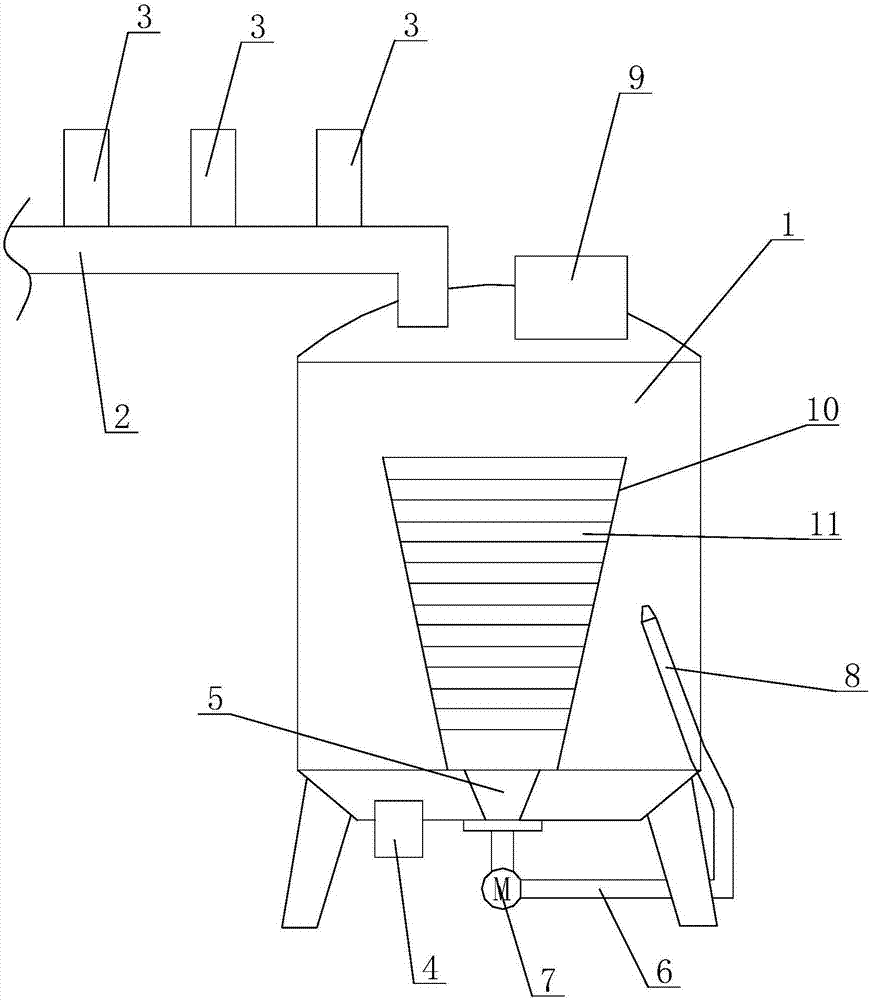

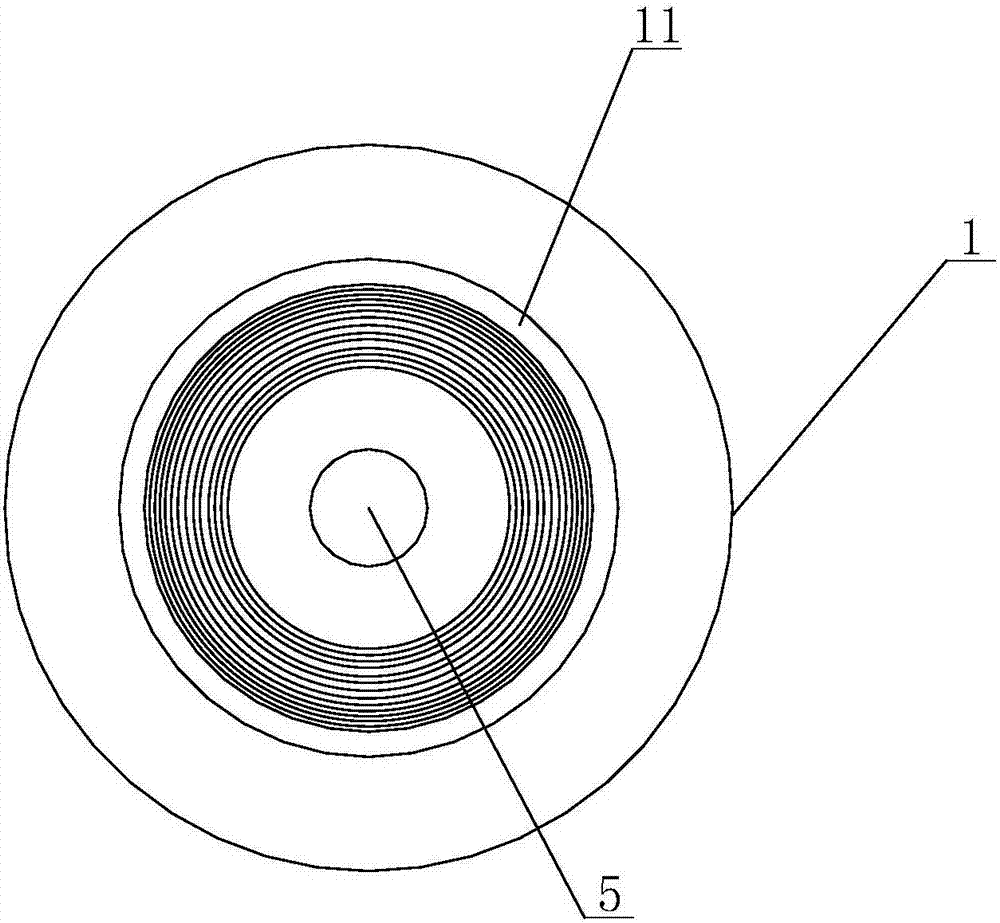

[0018] see figure 1 and figure 2 As shown, in this embodiment, a lubricating oil shaftless mixing tank includes a tank body 1, the top of the tank body 1 is provided with an infusion main pipe 2, and a plurality of infusion branch pipes 3 are connected to the infusion main pipe 2. Base oil or additives are introduced into several infusion branch pipes 3, a liquid outlet 4 is opened at the bottom of the tank body 1, and a circulation mixing port 5 is also opened at the bottom of the tank body 1, and the circulation mixing port 5 is on the upper side. The conical structure of large and small, the circulating mixing port 5 is connected with a circulating mixing pipeline 6, the circulating mixing pipeline 6 is provided with a circulating mixing pump 7, and the liquid outlet end of the circulating mixing pipeline 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com