Preparation method and application of casein-carrageenan self-loading nano-microcapsules

A technology of nano-microcapsules and casein, which is applied in the fields of application, food shaping, and the function of food ingredients, etc., can solve problems such as instability and difficulty in mixing uniformly, and achieve improved thermal stability, broad research value, protection and The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of casein-carrageenan self-loading nano-microcapsules in the present embodiment comprises the following steps:

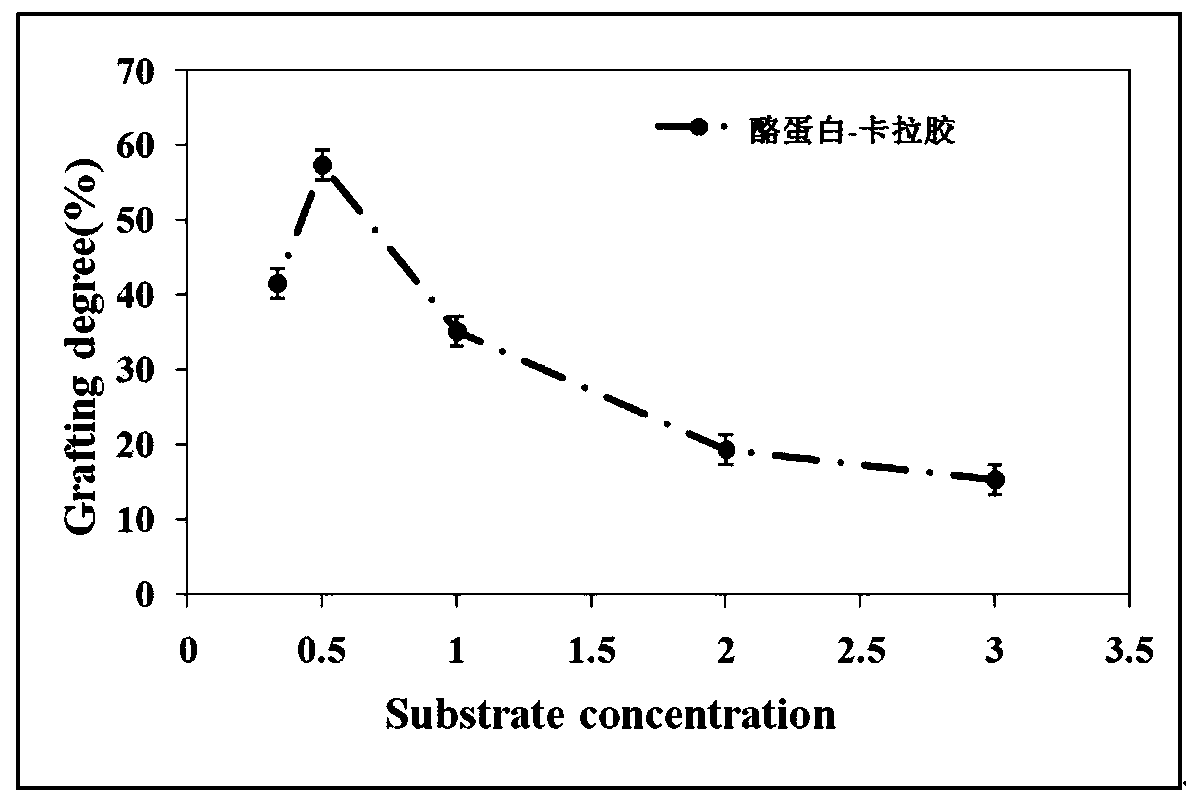

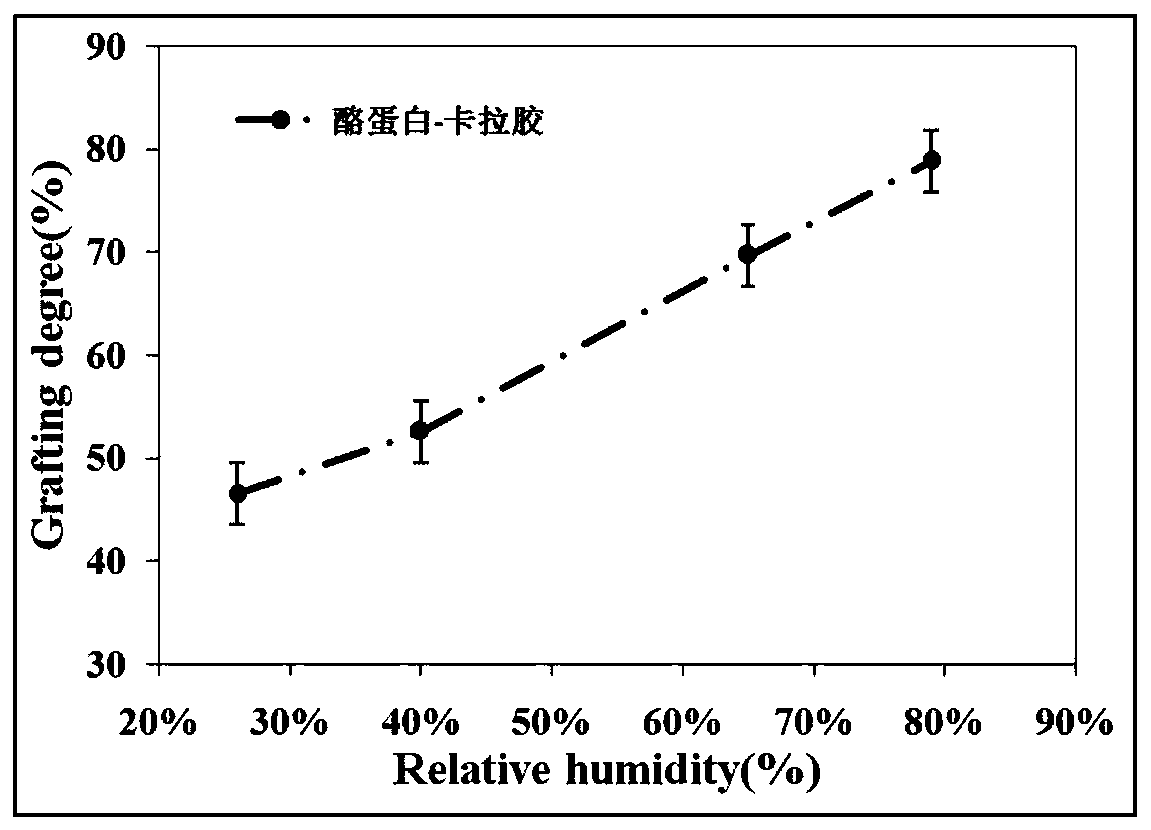

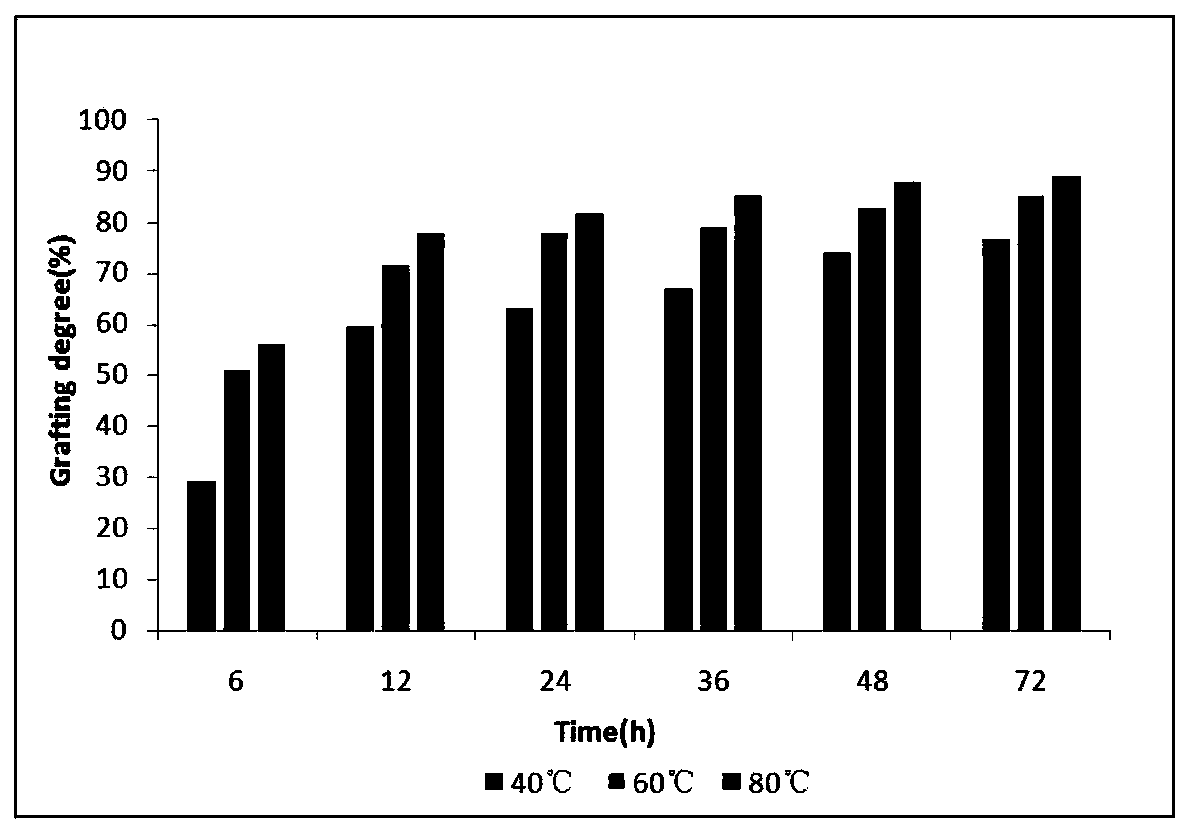

[0047] (1) Preparation of casein glycosylated copolymer: Dissolve casein in phosphate buffer, the pH of phosphate buffer is 7, magnetically stir at room temperature, prepare casein homogeneous solution, the concentration of casein homogeneous solution It is 2mg / ml, ultrasonic treatment under 250w power 5s-on, 5s-off; add carrageenan after collecting samples, the molar ratio of casein to carrageenan is 0.3:1, preferably 0.5:1, the relative Humidity is 70%, mixed evenly and freeze-dried, then the sample is ground into powder, and passed through a 120-mesh sieve, placed in a reaction vessel containing saturated potassium bromide and the reaction temperature is controlled at 40 ° C, pH is 7; Reaction 22 Hours later, the reaction was cooled to terminate the reaction, and the casein glycosylated copolymer was obtained.

[0048] As a preferen...

Embodiment 2

[0052] The preparation method of casein-carrageenan self-loading nano-microcapsules in the present embodiment comprises the following steps:

[0053] (1) Preparation of casein glycosylated copolymer: Dissolve casein in phosphate buffer, the pH of phosphate buffer is 7.4, magnetically stir at room temperature, prepare casein homogeneous solution, the concentration of casein homogeneous solution 2mg / ml, ultrasonic treatment under 250w power 5s-on, 5s-off; add carrageenan after collecting samples, the molar ratio of casein to carrageenan is 0.5:1, the relative humidity in the reaction vessel is 79%, mix After uniformity and freeze-drying, the sample was then ground into powder and passed through a 120-mesh sieve, placed in a reaction vessel containing saturated potassium bromide and the reaction temperature was controlled at 60°C and the pH was 7.5; the reaction was terminated by cooling after 24 hours of reaction, That is, the casein glycosylated copolymer is obtained.

[0054]...

Embodiment 3

[0058] The preparation method of casein-carrageenan self-loading nano-microcapsules in the present embodiment comprises the following steps:

[0059] (1) Preparation of casein glycosylated copolymer: Dissolve casein in phosphate buffer, the pH of phosphate buffer is 8, magnetically stir at room temperature, prepare casein homogeneous solution, the concentration of casein homogeneous solution 2mg / ml, ultrasonic treatment under 250w power 5s-on, 5s-off; add carrageenan after collecting samples, the molar ratio of casein to carrageenan is 0.8:1, the relative humidity in the reaction vessel is 80%, mix Freeze-dry after uniformity, then grind the sample into powder, pass through a 120-mesh sieve, place in a reaction vessel containing saturated potassium bromide and control the reaction temperature at 80°C, pH 8; cool to terminate the reaction after 26 hours of reaction, That is, the casein glycosylated copolymer is obtained.

[0060] As a preference, the molecular weight of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com