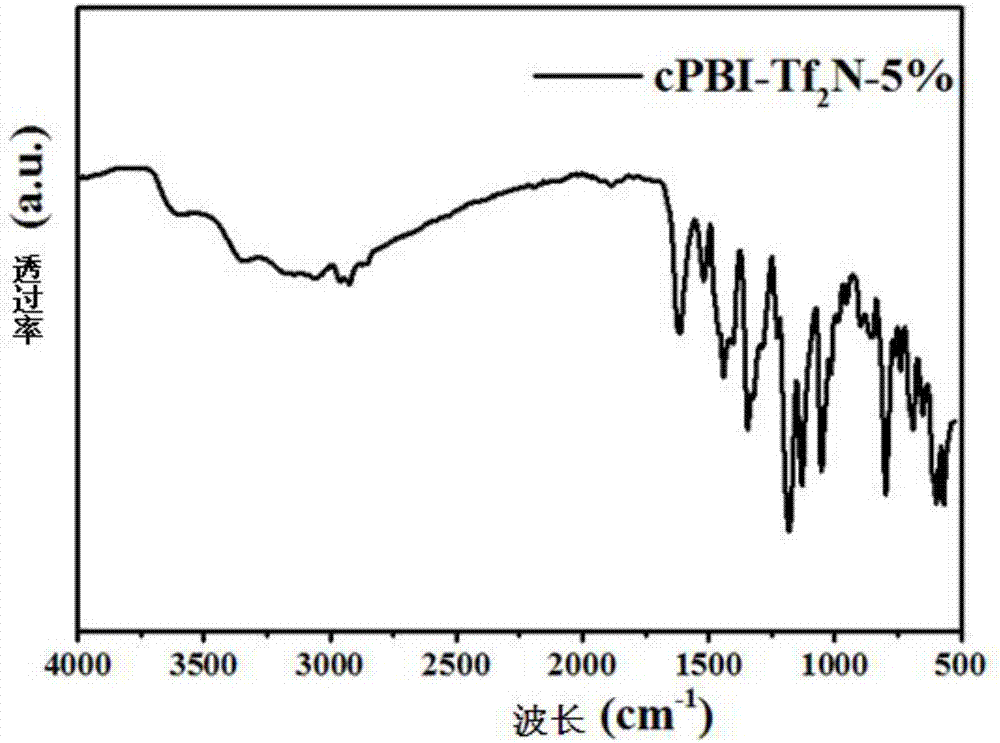

Polybenzoimidazole-poly (ionic liquid) cross-linked composite high temperature proton exchange membrane and preparation method thereof

A technology of polybenzimidazole and polyionic liquid, applied in fuel cells, electrochemical generators, electrical components, etc., can solve the problems of low proton conductivity and affecting the overall performance of high temperature proton exchange membrane fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

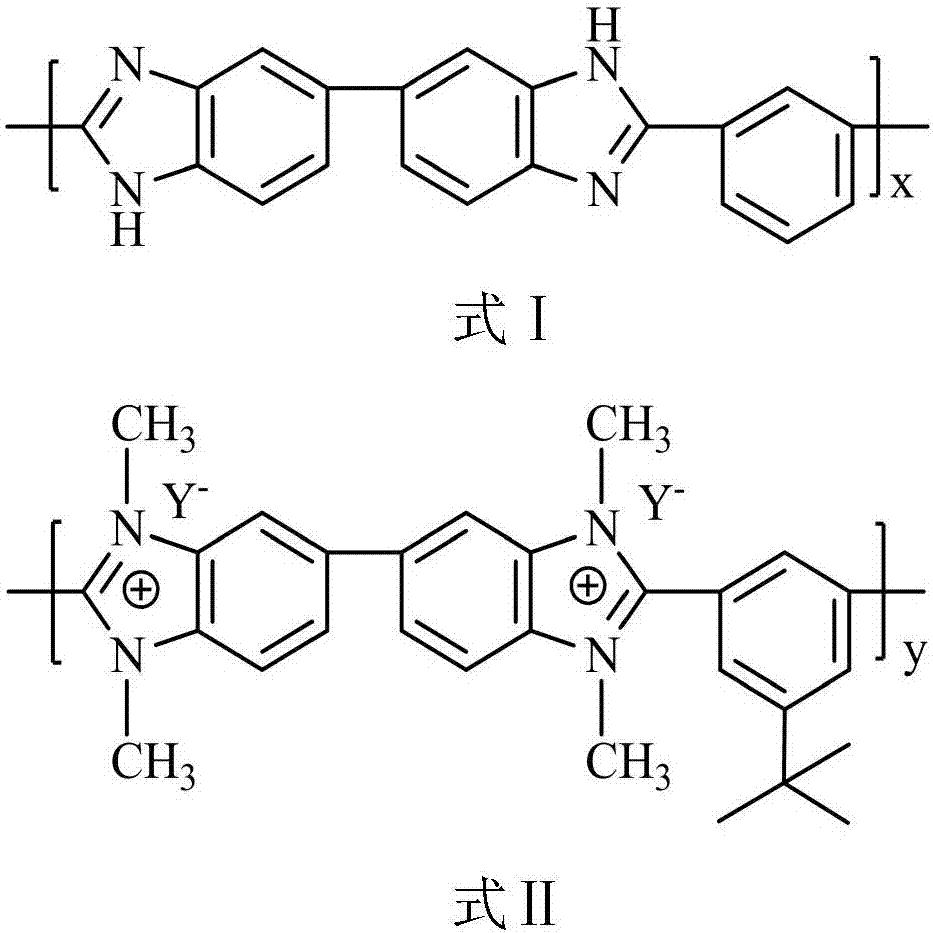

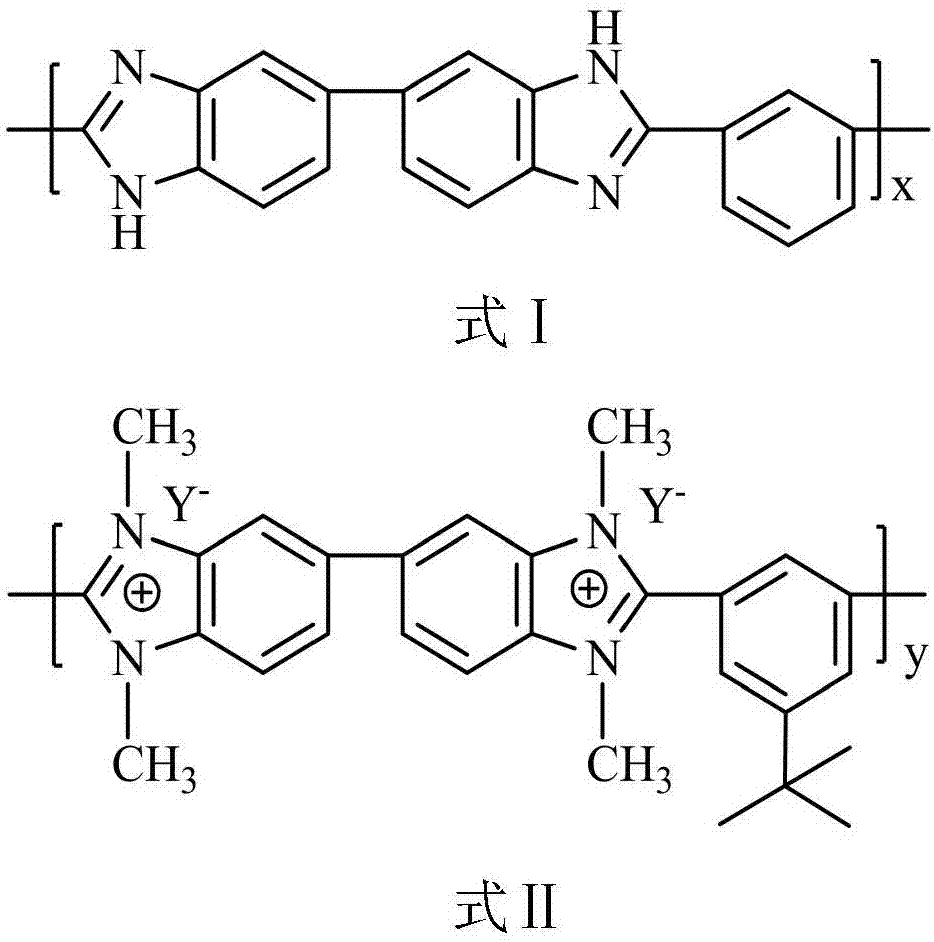

Method used

Image

Examples

Embodiment 1

[0056] Under the protection of nitrogen, add polyphosphoric acid as a solvent in a four-necked flask, add 0.015 mol 3,3',4,4'-tetraaminobiphenyl after heating for 1 hour, mix well and add 0.015 mol 5-tert-butyl Phthalic acid and 0.02 mol of phosphorus pentoxide were mixed uniformly again, and the temperature was raised to 190° C., and the reaction was continued for 30 hours, and poured into water to obtain polybenzimidazole.

Embodiment 2

[0058] Under the protection of nitrogen, add polyphosphoric acid as a solvent in a four-necked flask, add 0.015 mol 3,3',4,4'-tetraaminobiphenyl after heating for 1 hour, mix well and add 0.015 mol of isophthalic acid and 0.02 mol of phosphorus pentoxide, after mixing evenly again, raise the temperature to 195°C, continue the reaction for 25 hours, pour into water to obtain polybenzimidazole.

Embodiment 3

[0060] Under the protection of nitrogen, add polyphosphoric acid as a solvent in a four-necked flask, add 0.015 mol 3,3',4,4'-tetraaminobiphenyl after heating for 1 hour, mix well and add 0.015 mol 5-tert-butyl Phthalic acid and 0.02 mol of phosphorus pentoxide, after being uniformly mixed again, the temperature was raised to 200° C., and the reaction was continued for 20 hours, and poured into water to obtain polybenzimidazole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com