Bearing system of mining machinery

A bearing and mechanical technology, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of sliding bearings unable to provide axial support, poor impact resistance, etc., to achieve simple structure, large radial bearing capacity, bearing capacity powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

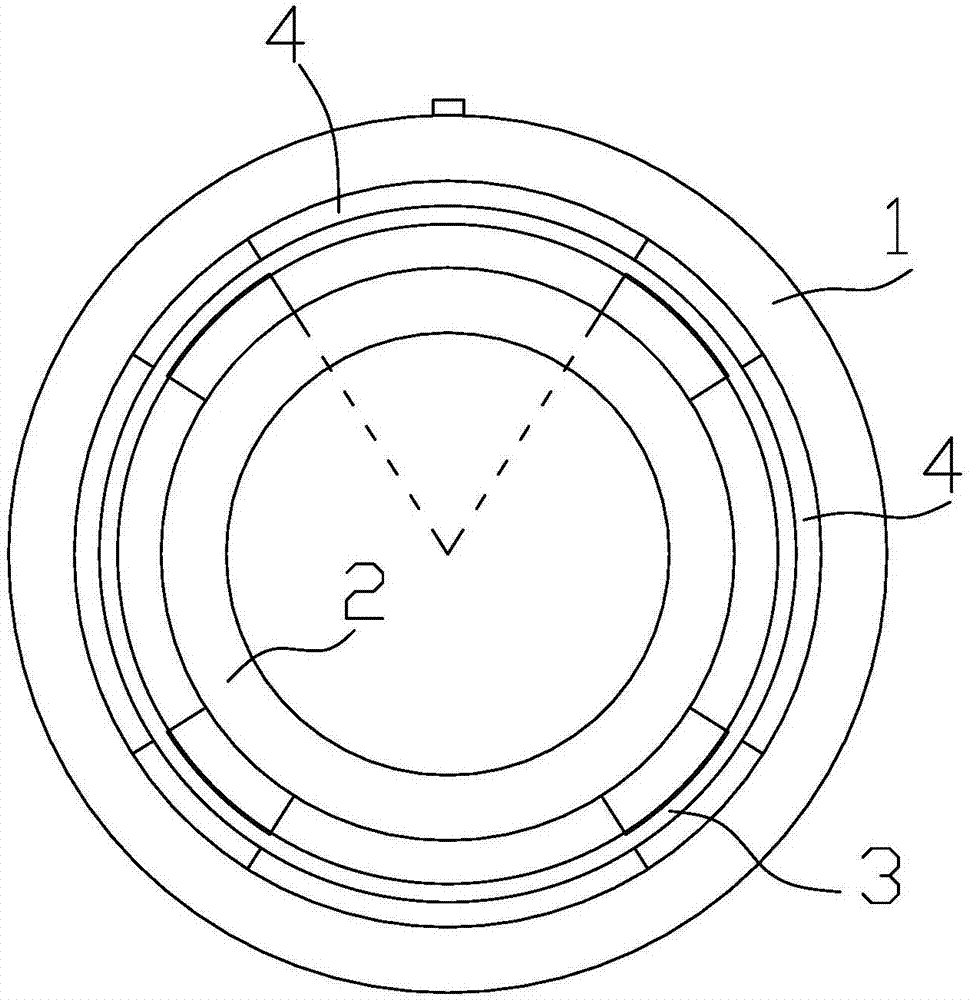

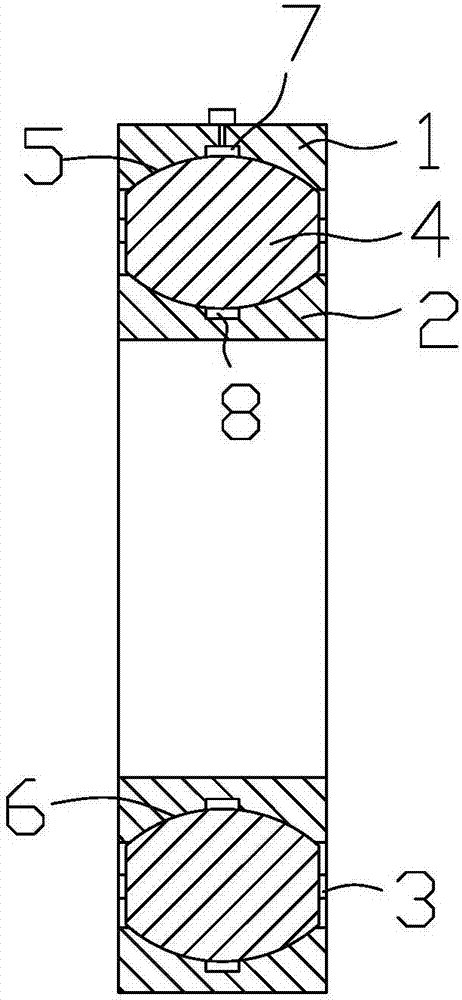

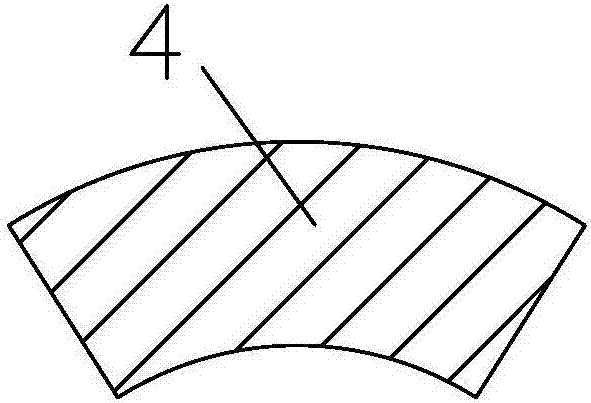

[0021] The invention discloses a bearing system for mining machinery, which comprises an outer ring and an inner ring which rotate relatively, the inner ring is sleeved in the outer ring and arranged coaxially, and a cage is also arranged between the outer ring and the inner ring; it is characterized in that : the inner side of the outer ring is provided with an annular inner slideway along its circumference, the outer side of the inner ring is provided with an annular outer slideway along its circumference, and a sliding body is arranged between the inner slideway and the outer slideway; The sliding body includes a plurality of sliding blocks with an arc-shaped structure, and the sliding block is provided with an upper curved surface corresponding to the outer slideway and a lower curved surface corresponding to the inner slideway; the upper curved surface The curvature of the outer slideway is the same as that of the outer slideway, and the axial width of the upper curved sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com