A kind of foamed aluminum plate for automobile and its foaming process

A foamed aluminum and sheet technology, which is applied in the field of foamed aluminum to achieve the effects of improving foaming effect, solving uneven foaming and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

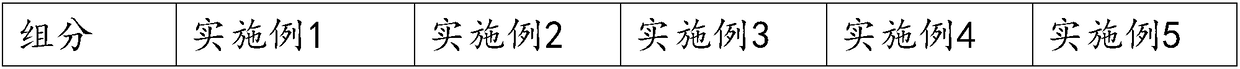

[0037] The aluminum foam proportioning in embodiment 1-5 is as follows:

[0038]

[0039]

[0040] The foaming process of embodiment 1-5 is as follows:

[0041] (1) Heat the tungsten to melt first, then slowly add lanthanum, stir while adding, continue stirring for 10 minutes after the addition, and then lower the temperature to 500°C to obtain a tungsten-lanthanum alloy;

[0042] (2) Heat the aluminum ingot to 550-700°C, then add calcium, titanium, magnesium, iron and zinc, stir while adding, and continue stirring for 10 minutes until all melted to obtain an aluminum master alloy;

[0043] (3) Put the tungsten-lanthanum alloy and the aluminum master alloy into the melting furnace together, heat and melt, and stir evenly to obtain a foamed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com