Method for preparing slump-retaining polycarboxylate water reducer by silylation of amino polyether end groups

An amino polyether and alkenyl silane coupling agent technology is applied in the field of preparing slump-preserving polycarboxylate water-reducing agents by silanization of amino polyether end groups, achieving the effects of convenient operation, enhanced slump-preserving effect, and improved application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

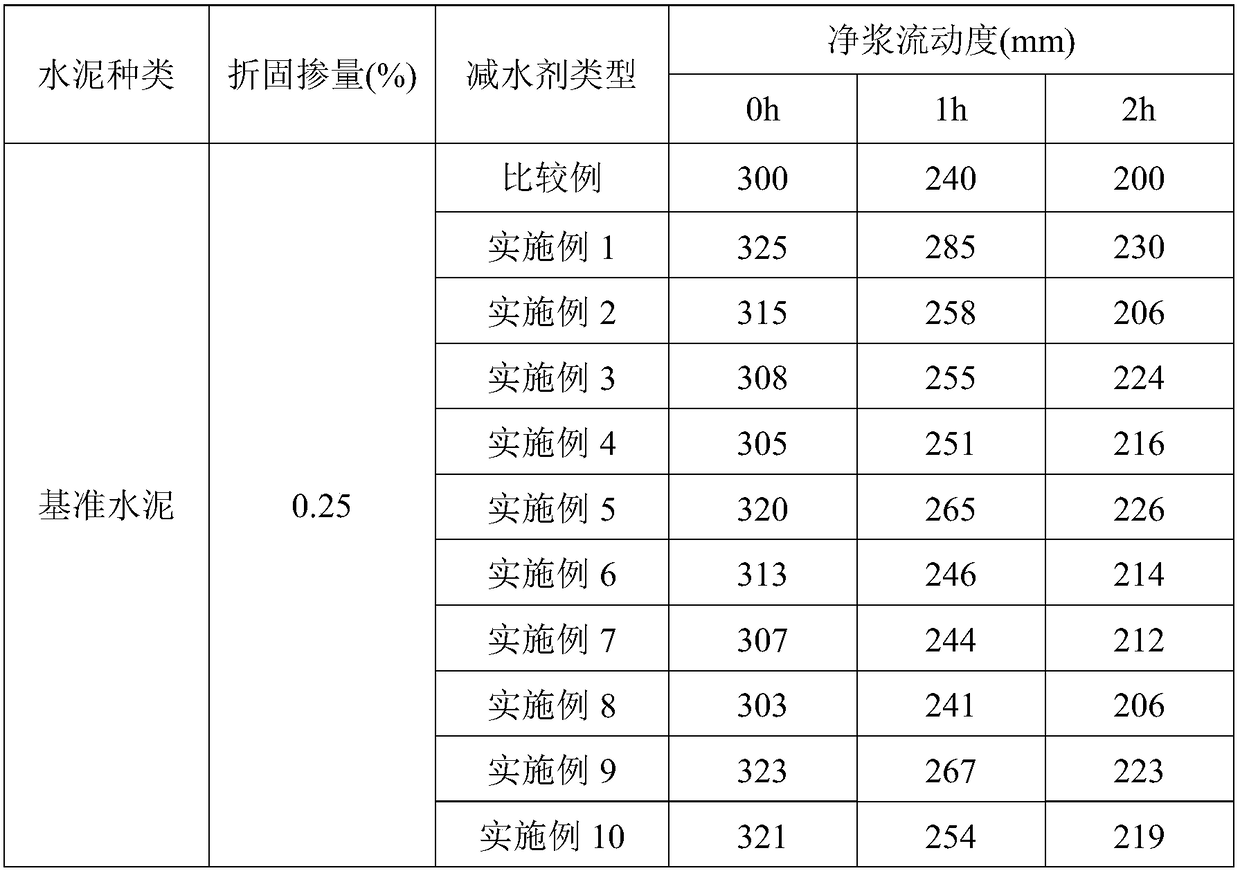

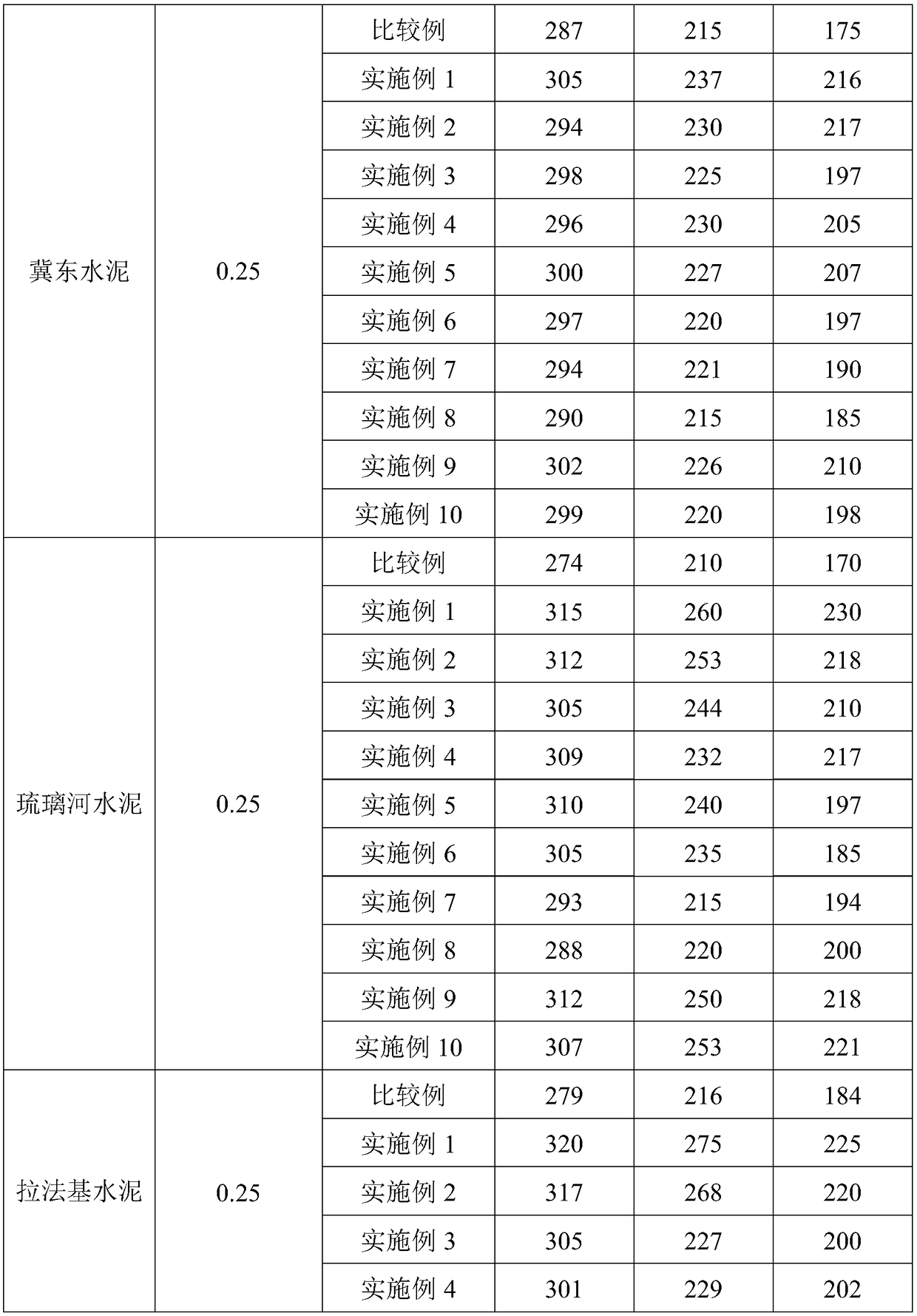

Examples

Embodiment 1

[0029] First, 7.3g of 3-bromopropyltrimethoxysilane, 131.4g of methanol, and 0.54g of water were sequentially added to the reactor, then 2.76g of formic acid was added to adjust the pH of the mixture to 4, and the temperature was raised to 30°C for 17 hours of hydrolysis to obtain 3 -The hydrolysis product of bromopropyltrimethoxysilane; 45g of amino-terminated lauryl polyoxyethylene ether (molecular weight=500) was added to another reaction vessel, 36g of water was added, stirred and heated to 50°C, and then 2.01 The hydrolyzate of g3-bromopropyltrimethoxysilane and 15.12g sodium bicarbonate were heated up to 100°C for 3 hours, then purified 5 times with a methanol-water mixed solvent with a volume ratio of 2:1, and then vacuum-dried to obtain Terminal group silylation modified polyether product; take 0.41g allyltriethoxysilane, 7.38g methanol, 0.11g water and add them to the reactor successively, then add 0.18g formic acid to adjust the pH of the mixed solution to 4, and heat...

Embodiment 2

[0031] After the polycarboxylate superplasticizer solution with a concentration of 35% obtained in Example 1 was stored at 6° C. for 30 days, its implementation effect was measured.

Embodiment 3

[0033] First, 5.96g of 3-chloropropyltrimethoxysilane, 23.84g of ethanol, and 1.62g of water were sequentially added to the reactor, then 0.18g of acetic acid was added to adjust the pH of the mixture to 5, and the temperature was raised to 60°C for 2 hours for hydrolysis to obtain 3 - Hydrolyzed product of chloropropyl trimethoxy silicon; take 90g of aminomethoxy polyoxyethylene ether (molecular weight = 3000) and add it to another reaction vessel, add 108g of water, stir and heat up to 60°C, and then add 4.7g of the hydrolyzed product of 3-chloropropyltrimethoxysilane and 1.26g of sodium bicarbonate were heated up to 60°C for 7 hours, then purified 3 times with a methanol-water mixed solvent with a volume ratio of 1:1, and then vacuum-dried. Obtain end group silylation modified polyether product; take 1.47g vinyltrimethoxysilane, 5.88g ethanol, 2.32g water and add to the reactor successively, then add 0.06g acetic acid to adjust the pH of the mixed solution to 5, and raise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com