Method for preparation of rich slurry vibrating cemented sand and gravel and its use in anti-seepage protection structure construction

A cemented sand and gravel technology, applied in the field of cemented sand and gravel dam construction, can solve problems such as uneven distribution of grout, honeycomb pockmarks, etc., and achieve the effect of avoiding uneven distribution of grout and controlling construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

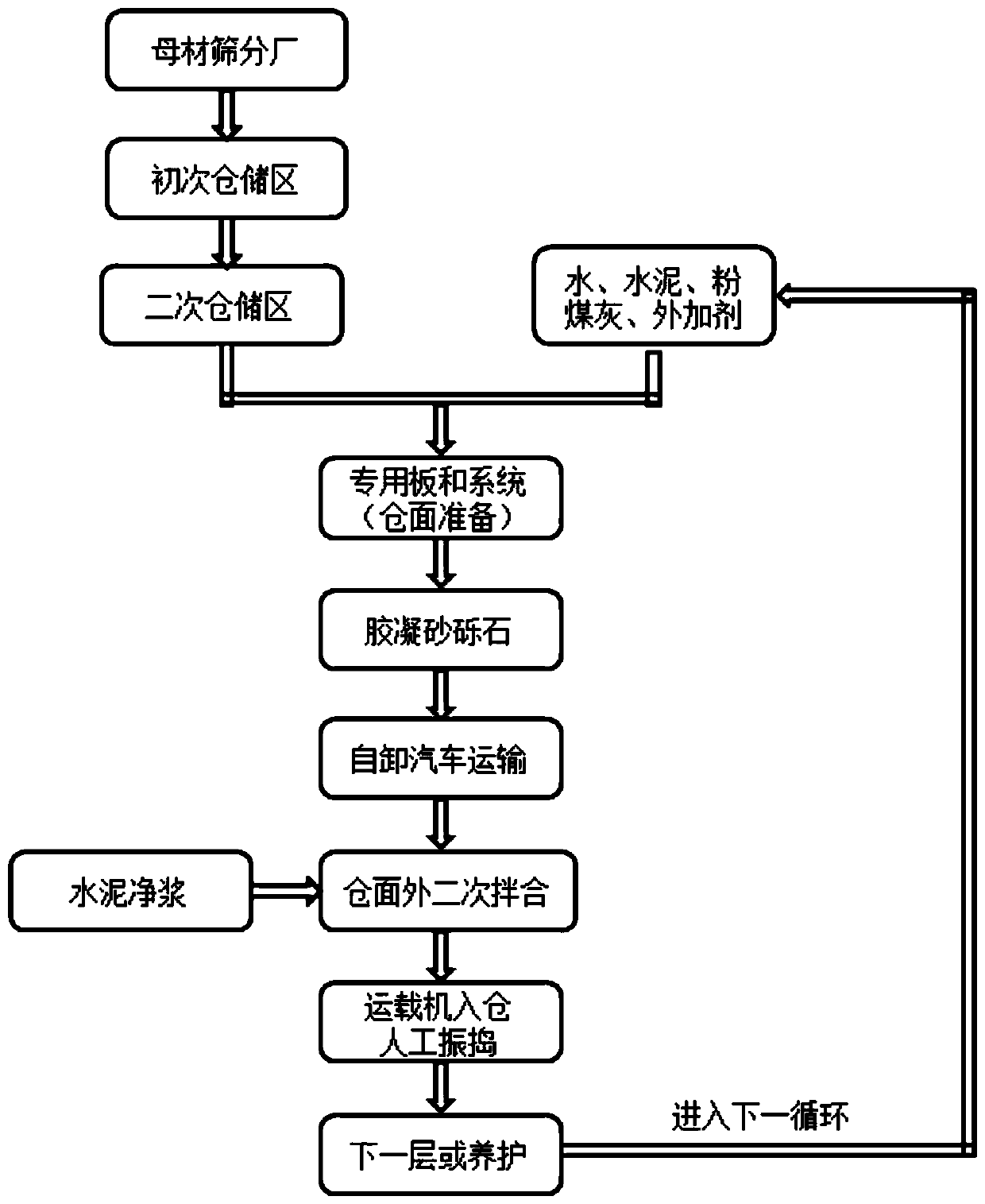

[0026] A preparation method of rich slurry vibrating cemented sand and gravel comprises the following contents:

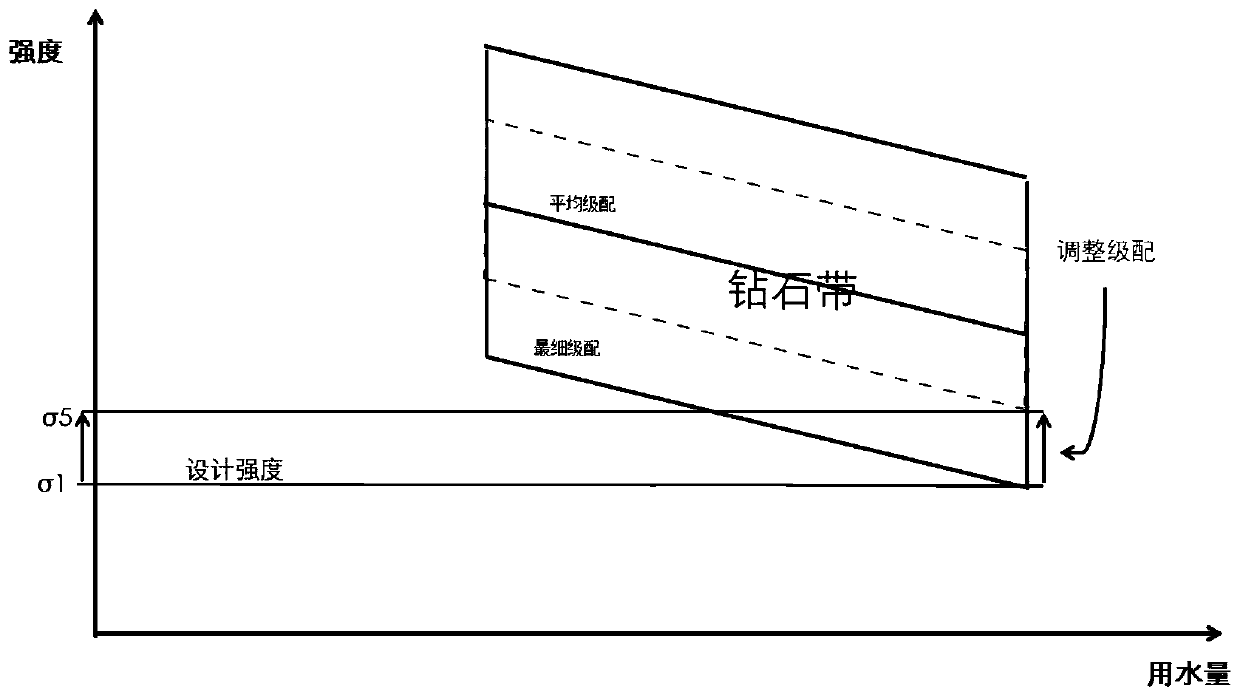

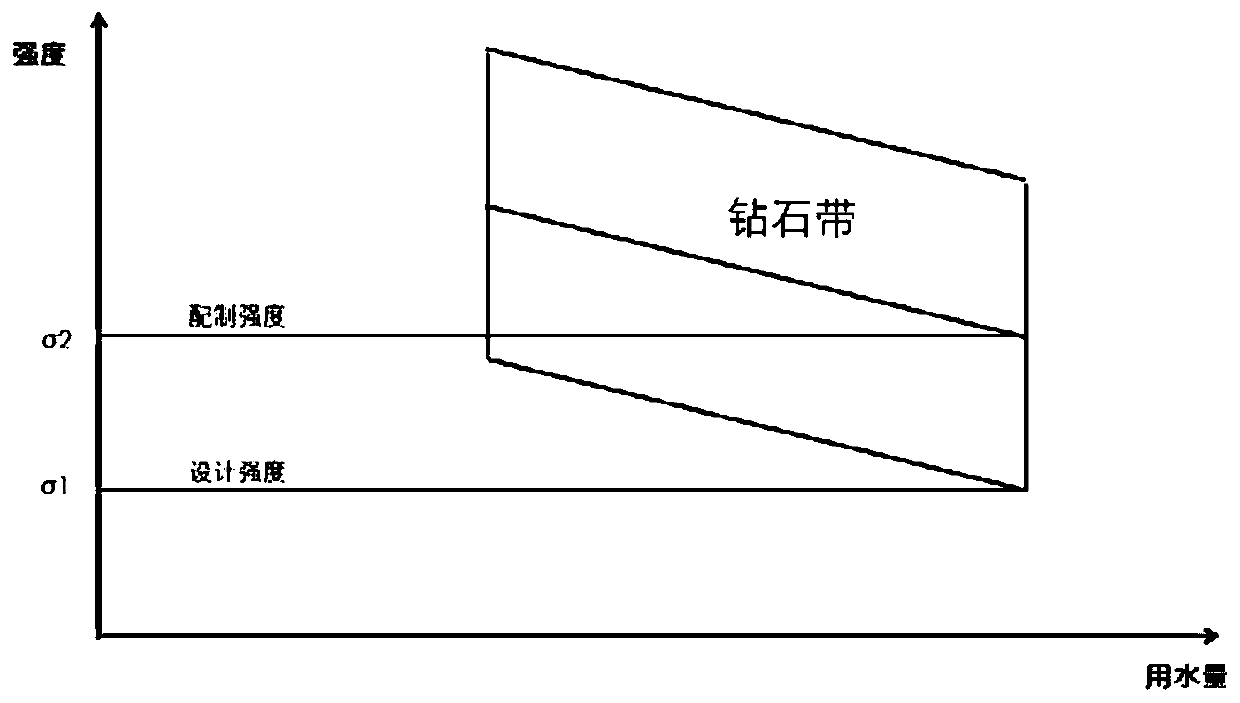

[0027] Step 1: Collect natural sand and gravel at the construction site, remove particles with a particle size above 80mm, and use the graded sand and gravel as the gravel material for preparing the parent material. The gradation of the sand and gravel obtained in this way is relatively discrete, and the degree of dispersion of the aggregate should be simply screened, re-mixed or externally mixed to control the size of the diamond band. The representative gradation of the gravel is determined as follows: The fine gradation is used as the first boundary gradation, and the average gradation of natural sand and gravel is used as the second boundary gradation, such as figure 1 shown.

[0028] Step 2: Prepare the water-binder ratio according to the workability and corresponding strength and durability indicators to obtain the corresponding amount of gelling material, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com