Preparation method of supersaturation Mg(Ti) metal solid solution powder

A solid solution and powder technology, applied in the field of supersaturated Mg metal solid solution powder preparation, can solve the problems of insufficient ball milling energy, uneven solid solubility, long ball milling time, etc. The effect of fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

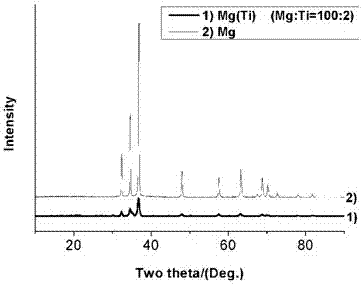

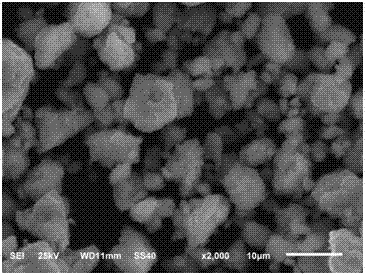

[0030] A preparation method of supersaturated Mg (Ti) metal solid solution powder, the steps are as follows:

[0031] 1) First put Mg powder and Ti powder into the ball mill tank according to the atomic ratio of Mg:Ti=100:2, the particle size of Mg powder and Ti powder are both less than 100 mesh, the total mass of the two powders is 3g, and then put grinding ball;

[0032] 2) The electrode rod is installed on the cover plate of the ball mill tank, and the cover plate is covered. The electrode rod is located in the middle of the inside of the tank body, and the electrode rod and the outer surface of the ball mill tank are respectively connected to the two poles of the high-voltage AC power supply;

[0033] 3) Use a vacuum pump to evacuate the closed ball mill tank for 5 minutes, then fill it with argon, repeat it 4 times, reduce the water and oxygen content in the ball mill tank, and fill the gas medium for the last time to make the air pressure in the ball mill tank 0.1atm ;...

Embodiment 2

[0041] A preparation method of supersaturated Mg (Ti) metal solid solution powder, the steps are as follows:

[0042] 1) First put Mg powder and Ti powder into the ball mill tank according to the atomic ratio of Mg:Ti=100:5, the particle size of Mg powder and Ti powder are both less than 100 mesh, the total mass of the two powders is 10g, and then put grinding ball;

[0043] 2) The electrode rod is installed on the cover plate of the ball mill tank, and the cover plate is covered. The electrode rod is located in the middle of the inside of the tank body, and the electrode rod and the outer surface of the ball mill tank are respectively connected to the two poles of the high-voltage AC power supply;

[0044] 3) Use a vacuum pump to evacuate the closed ball mill tank for 10 minutes, then fill it with argon, repeat the process twice, reduce the water and oxygen content in the ball mill tank, and fill the gas medium for the last time to make the air pressure in the ball mill tank ...

Embodiment 3

[0051] A preparation method of supersaturated Mg (Ti) metal solid solution powder, the steps are as follows:

[0052] 1) First put Mg powder and Ti powder into the ball mill tank according to the atomic ratio of Mg:Ti=100:3, the particle size of Mg powder and Ti powder are both less than 100 mesh, the total mass of the two powders is 5g, and then put grinding ball;

[0053] 2) The electrode rod is installed on the cover plate of the ball mill tank, and the cover plate is covered. The electrode rod is located in the middle of the inside of the tank body, and the electrode rod and the outer surface of the ball mill tank are respectively connected to the two poles of the high-voltage AC power supply;

[0054] 3) Use a vacuum pump to evacuate the closed ball milling tank for 8 minutes, then fill it with argon, repeat the process 3 times, reduce the water and oxygen content in the ball milling tank, and fill the gas medium for the last time to make the air pressure in the ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com