An assembled self-insulating metal decorative exterior wall panel

A metal decoration and exterior wall panel technology, applied in covering/lining, building, floor, etc., can solve the problems of lack of heat preservation, heat insulation, fire prevention, sound insulation, waterproof, frost-resistant exterior wall panels, etc., and achieve easy transportation The effects of lifting construction, reducing requirements, and improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

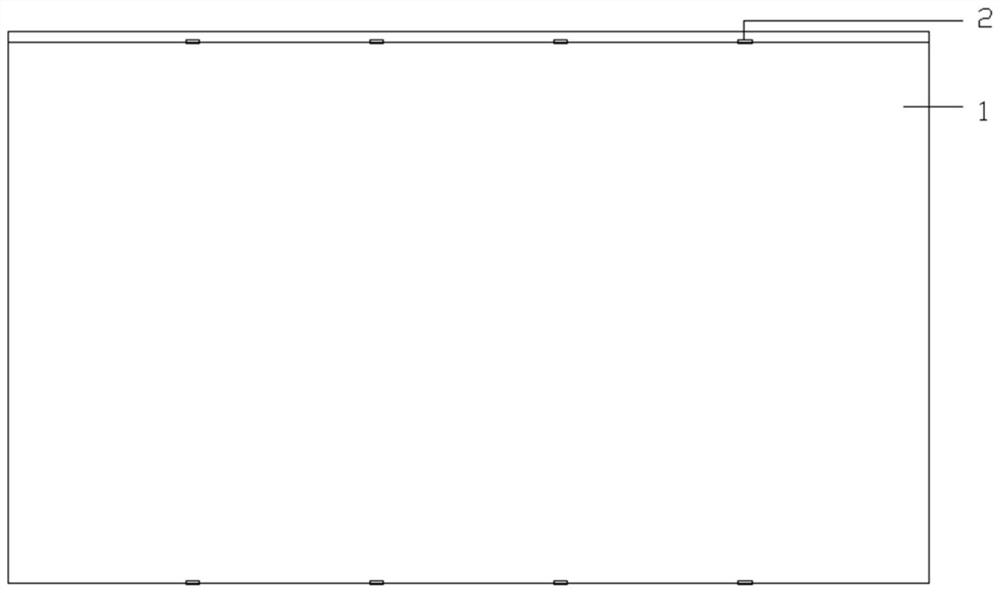

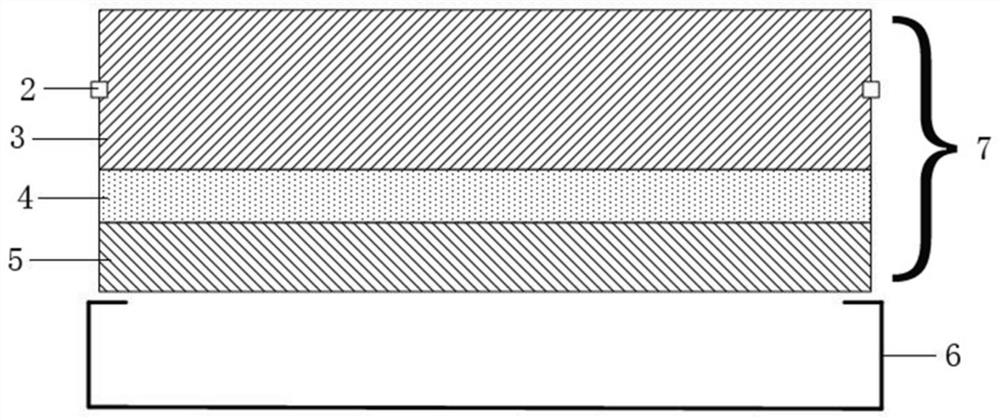

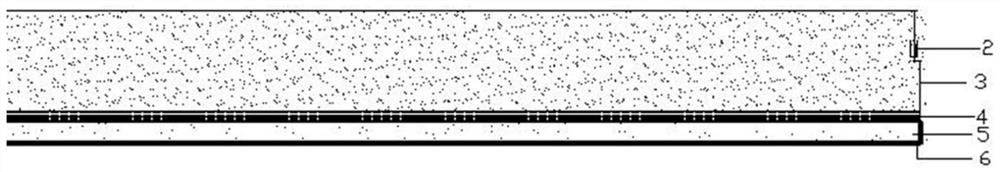

[0041] An assembled self-insulating metal decorative exterior wall panel with a thickness of 200mm, including a wall 7 composed of lightweight high-specific-strength high-porosity concrete 5, an insulation layer 4 and light-weight high-specific-strength low-porosity concrete 3, and is arranged on the wall 7. The metal shell 6 on the outside, the metal shell 6 adopts galvanized steel plate with decorative effect, and adopts a triangular push-in connection device.

[0042] The lightweight, high-specific-strength, high-porosity concrete layer 5 in the wall 7 has a thickness of 50mm and a dry density of 800kg / m 3 About, thermal conductivity 0.15W / (m 2 About K), the solid cube is made of light aggregate porous concrete with a compressive strength of about 7.5MPa; the formula of the material used is: P.II 42.5 cement 280kg / m 3 , ceramic hollow microspheres 70kg / m 3 , yellow sand 100kg / m 3 , light coarse aggregate of density grade 700 400kg / m 3 , tap water 105kg / m 3 , mixed foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com