Coating composition for solar cell backboards and solar cell backboards which are coated by coating composition

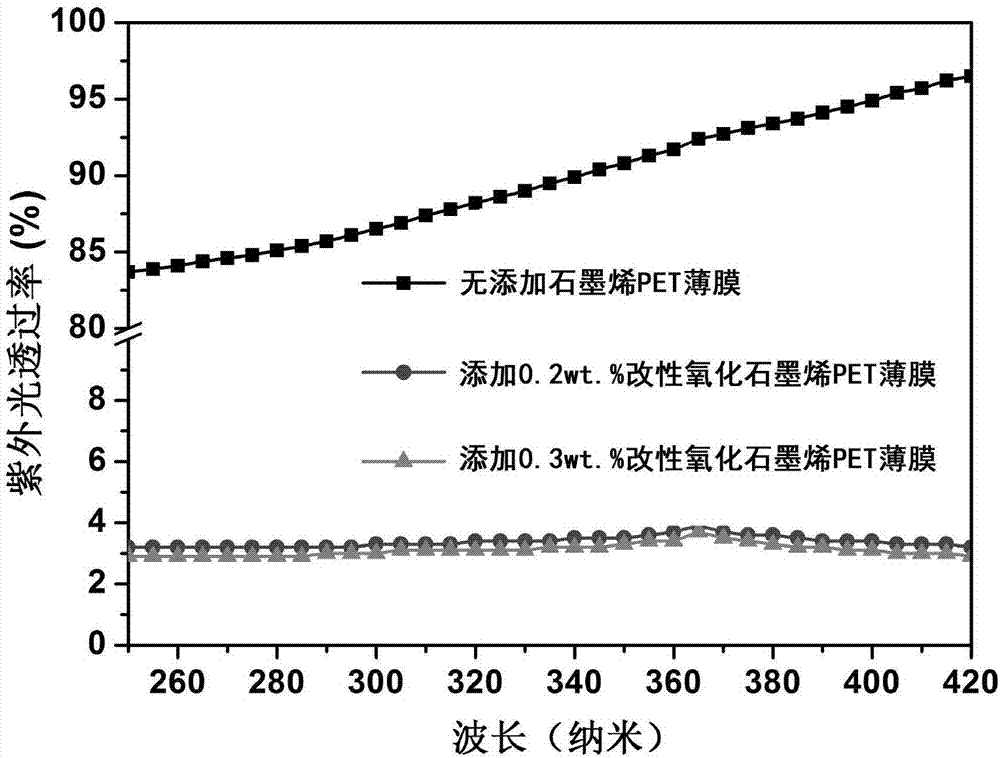

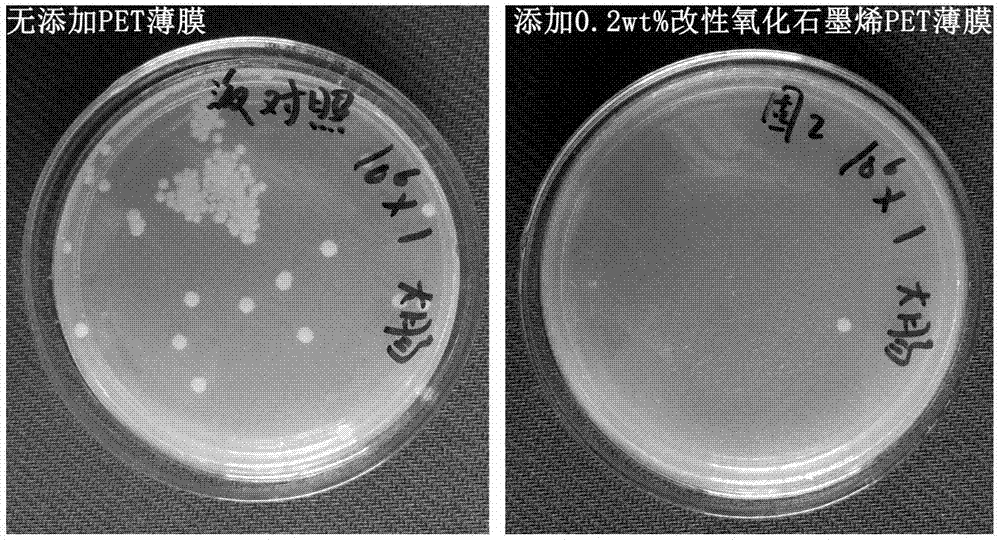

A technology of solar cells and compositions, applied in fire-resistant coatings, epoxy resin coatings, antifouling/underwater coatings, etc., can solve problems such as complex processes, and achieve the effects of good UV resistance, strong adhesion and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment relates to the preparation of a kind of coating composition for solar battery backplane:

[0041] 1. Ingredients according to the following formula:

[0042]

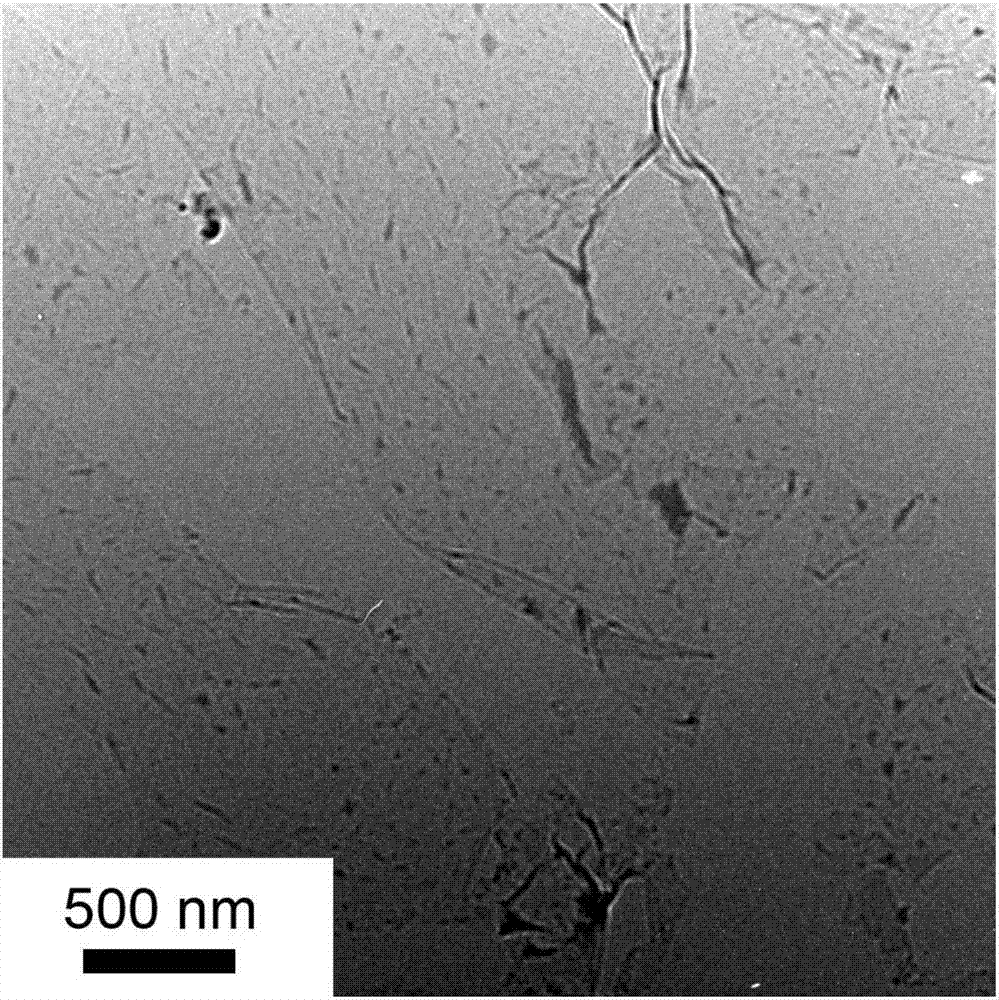

[0043] 2. Add 1 part of modified graphene and 30 parts of butyl acetate into an organic-resistant container, stir thoroughly for 30 minutes, and ultrasonicate for 5 minutes until no large pieces of visible graphene exist. Then add 30 parts of FEVE and 10 parts of titanium dioxide, stir for 30 minutes and then filter. Finally, 5 parts of isocyanate were added and after 10 minutes of stirring the desired coating was obtained. The preparation method of modified graphene is: disperse the graphite oxide of 5g in the 5L large beaker, disperse ultrasonically for 40min, then heat to 35 degrees and add the phosphate ester coupling agent solution of 15g solid content under mechanical stirring, add the acetic acid of 10ml, After the reverse precipitation, suction filtration and drying, repeated washing ...

Embodiment 2

[0049] This embodiment relates to the preparation of a kind of coating composition for solar battery backplane:

[0050] 1. Ingredients according to the following formula:

[0051]

[0052] 2. Add 0.1 parts of modified graphene and 30 parts of butyl acetate into an organic-resistant container, stir thoroughly for 30 minutes, and ultrasonicate for 5 minutes until no large pieces of visible graphene exist. Then add 30 parts of FEVE and 10 parts of titanium dioxide, stir for 30 minutes and then filter. Finally, 5 parts of isocyanate were added and after 10 minutes of stirring the desired coating was obtained. The preparation method of modified graphene is: disperse 5g of graphite oxide in a 5L large beaker, disperse ultrasonically for 40min, then heat to 35 degrees and add 15g of aluminate coupling agent solution with solid content under mechanical stirring, and add 10ml of Acetic acid, suction filtration drying after reverse precipitation, when repeated washing causes no mo...

Embodiment 3

[0055] This embodiment relates to the preparation of a kind of coating composition for solar battery backplane:

[0056] 1. Ingredients according to the following formula:

[0057]

[0058] 2. Add 0.01 parts of modified graphene and 30 parts of butyl acetate into an organic-resistant container, stir thoroughly for 30 minutes, and ultrasonicate for 5 minutes until no large pieces of visible graphene exist. Then add 30 parts of FEVE and 10 parts of titanium dioxide, stir for 30 minutes and then filter. Finally, 5 parts of isocyanate were added and after 10 minutes of stirring the desired coating was obtained. The preparation method of modified graphene: disperse 5g of graphite oxide in a 5L large beaker, disperse ultrasonically for 40min, then heat to 35 degrees and add 5g of octadecyl ammonium bromide solution with solid content under mechanical stirring, reverse precipitation After suction filtration and drying, when no modifying agent remains after repeated washing (each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com