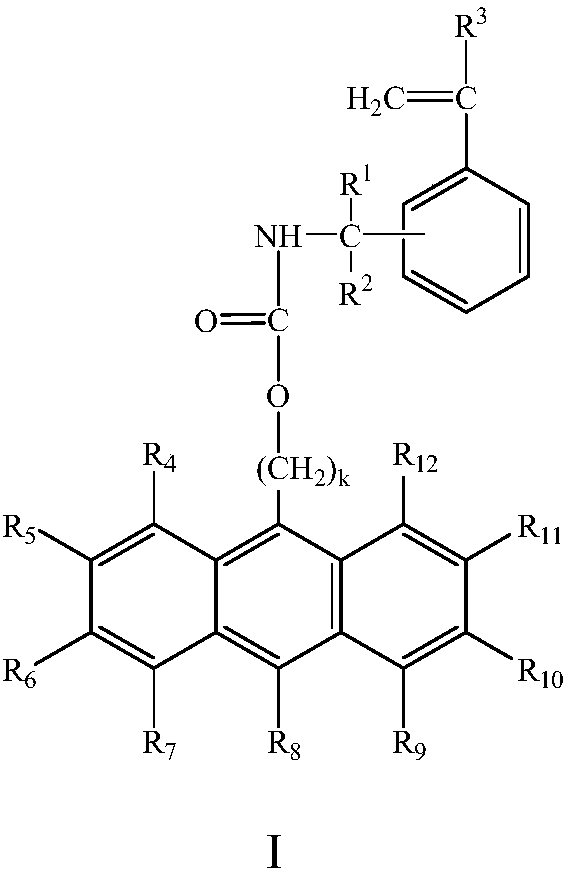

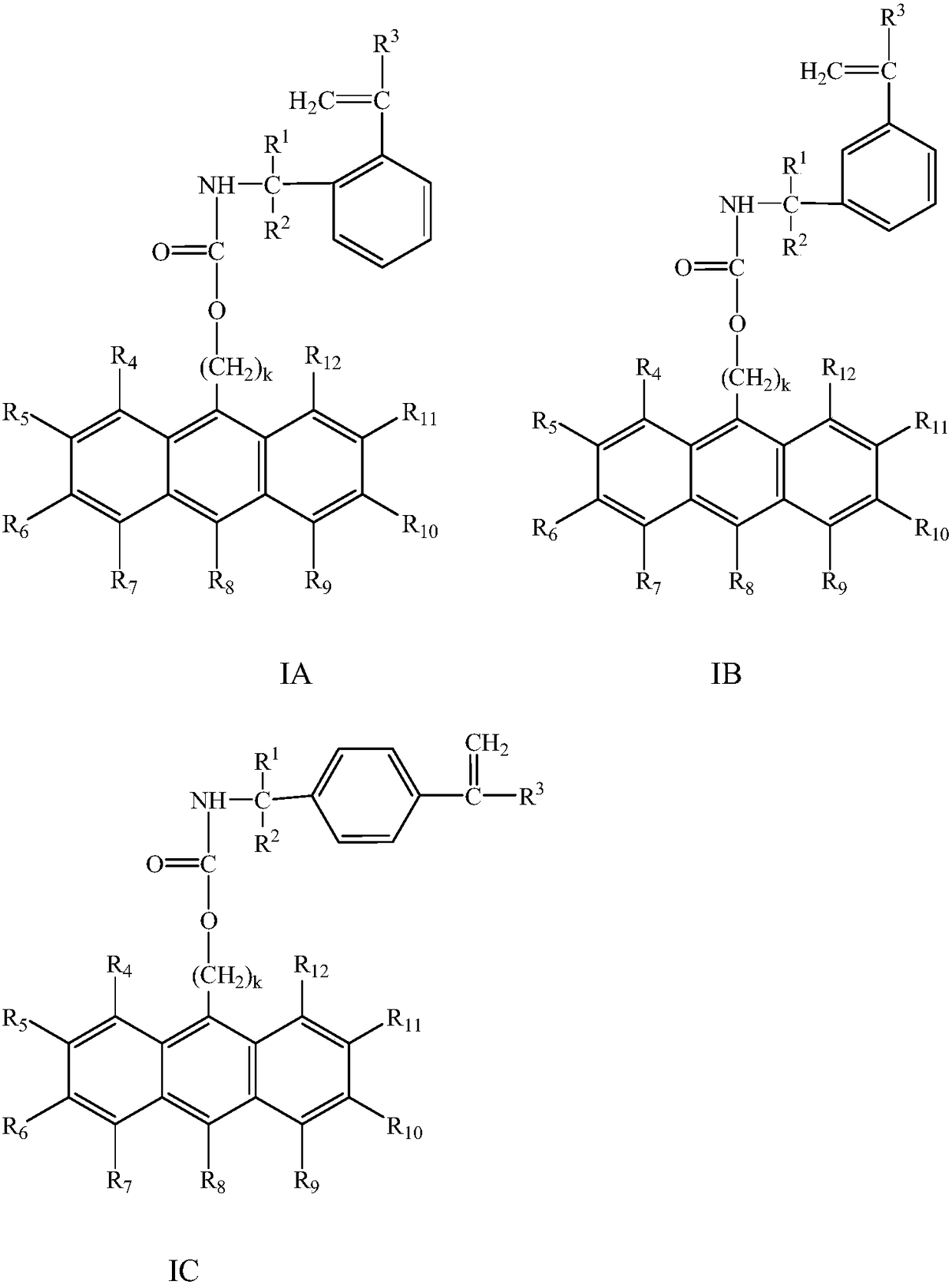

Hydrophobic monomer, high molecular polymer and its preparation method and application

A technology of high molecular polymer and hydrophobic monomer is applied in the preparation of organic compounds, the preparation of carbamic acid derivatives, the composition of drilling holes, etc. Limiting the popularization and application of solid-free drilling fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

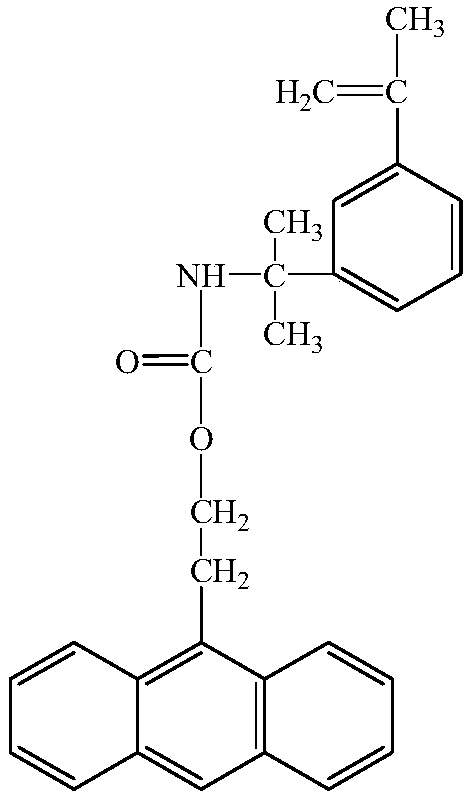

Embodiment 1

[0053] Add 500 mL of acetonitrile and 22.23 g of 9-(2-hydroxyethyl)anthracene into a dry three-neck flask equipped with a stirrer, condenser and dropping funnel, and stir until 9-(2-hydroxyethyl)anthracene is fully dissolved. The water bath was heated to a temperature of 65°C, and vacuum was applied for 2 hours to remove moisture. Under nitrogen protection, 0.0221 g of dibutyltin dilaurate was added. 22.14 g of 3-isopropyl-dimethylbenzyl isocyanate in the dropping funnel was dropped into a three-necked flask, reacted for 7.5 hours, and distilled under reduced pressure to remove acetone, and the crude product of the target molecule was obtained. The crude product was rinsed with methanol three times, and placed in an oven at 65° C. until constant weight to obtain the target product.

Embodiment 2

[0055] Add 42.64g of acrylamide, 9.41g of sodium acrylate, 20.62g of sodium p-styrenesulfonate and 700mL of distilled water into the reactor in sequence, and stir until the monomers are dissolved. In reactor, add 24.0g sodium dodecylbenzene sulfonate, add the hydrophobic monomer that 3.88g embodiment 1 prepares after stirring, stir at high speed, make hydrophobic monomer solubilization in sodium dodecylbenzenesulfonate in micelles. Nitrogen was introduced for 30 minutes to eliminate dissolved oxygen in the reaction system and provide an oxygen-free reaction atmosphere. The water bath was warmed up to a predetermined temperature of 45°C, and 0.8g (NH 4 ) 2 S 2 o 8 , and reacted for 12 hours under continuous stirring conditions to obtain a colorless and transparent gum-like crude product. The crude product was purified by precipitation with absolute ethanol, and dried in a vacuum oven at 25° C. to a constant weight to obtain a high molecular weight polymer.

Embodiment 3

[0057] Add 90.53g of N-isopropylacrylamide, 21.62g of sodium methacrylate, 82.47g of sodium p-styrenesulfonate and 786.08mL of distilled water into the reactor in sequence, and stir until the monomers are dissolved. Add 30.5g sodium octadecylsulfonate to the reactor, add 2.97g hydrophobic monomer prepared in Example 1 after stirring evenly, stir at a high speed, so that the hydrophobic monomer is solubilized in the micelles of sodium octadecylsulfonate middle. Nitrogen was introduced for 30 minutes to eliminate dissolved oxygen in the reaction system and provide an oxygen-free reaction atmosphere. The water bath was warmed up to a predetermined temperature of 55°C, and 2.0 g (NH 4 ) 2 S 2 o 8 , and reacted for 8 hours under continuous stirring conditions to obtain a colorless and transparent gum-like crude product. The crude product was purified by precipitation with absolute ethanol, and dried in a vacuum oven at 35° C. to a constant weight to obtain a high molecular wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com