Nitrogen-doped porous vertical graphene nanowall array and preparation method and application thereof

A graphene nano-wall and nitrogen-doped technology, which is applied in the field of nano-materials, can solve the problems of high cost, difficulty in obtaining VAGN, and high technical requirements of PECVD, so as to prevent interlayer accumulation, easy control of reaction conditions and processes, and unstructured will have a destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a nitrogen-doped porous vertical graphene nanowall array, comprising the following steps:

[0036] (1) Activate the carbon cloth and prepare the nickel hydroxide precursor growth solution, cut the carbon cloth into a size of 1cm*2cm, arrange the carbon in an oven with a volume ratio of 1:1 ethanol and 30% hydrogen peroxide solution and heat it to 60 ℃ for 24 hours to obtain activated carbon cloth. The nickel hydroxide precursor growth solution formula is a mixed solution of 0.15M / L nickel chloride hexahydrate and 0.3M / L hexamethylenetetramine.

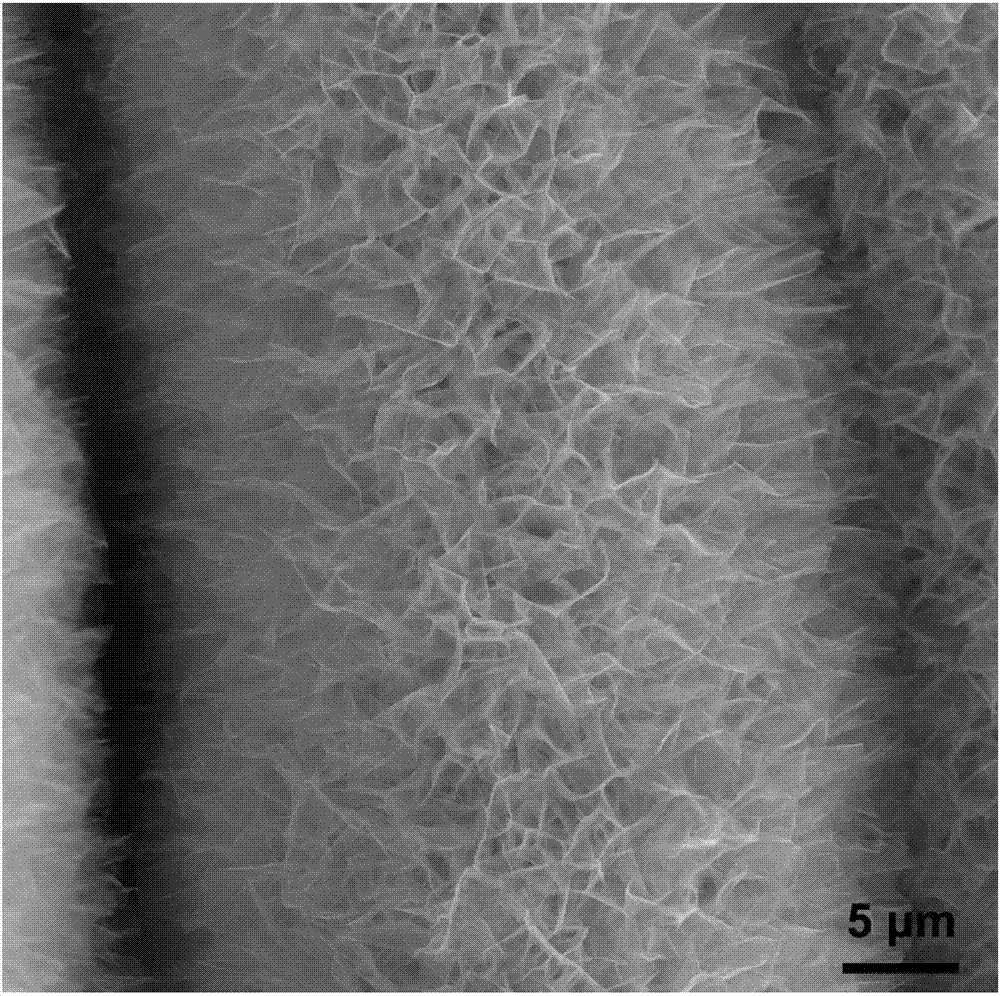

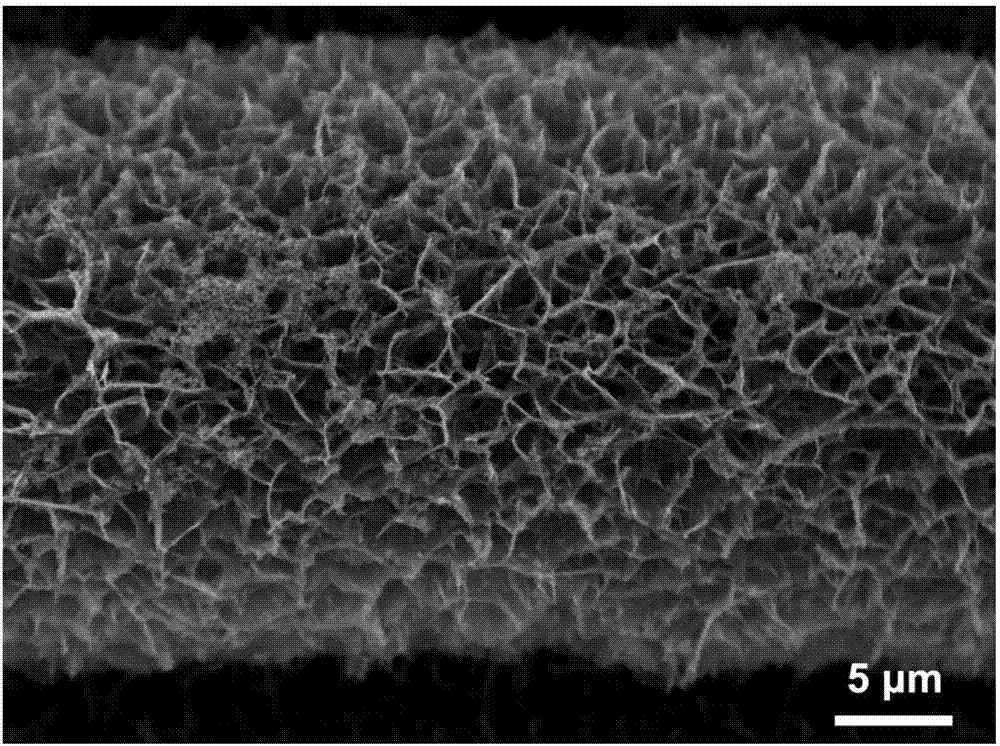

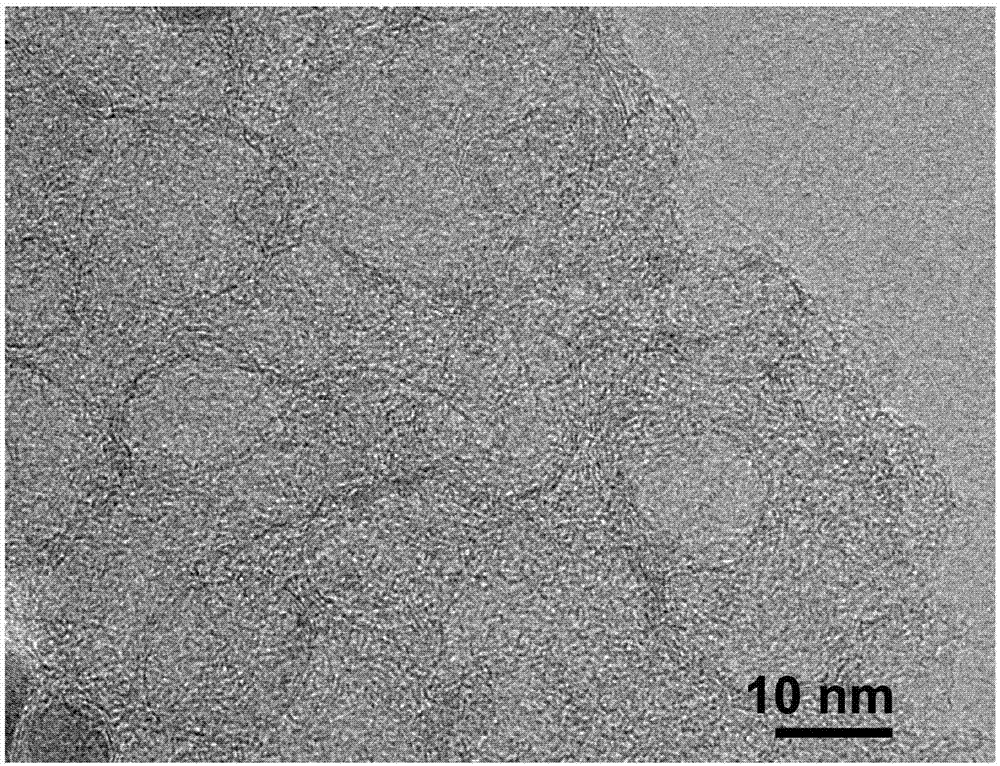

[0037] (2) The activated carbon is arranged in the nickel hydroxide precursor growth solution, heated to 100°C in an oven for 10 hours to grow nickel hydroxide to obtain nickel hydroxide / carbon cloth, and nickel hydroxide grows on the carbon cloth. Scanning electron microscope (SEM) image of nickel hydroxide / carbon cloth figure 1 shown.

[0038] (3) The obtained nickel hydroxide / carbon is arranged in t...

Embodiment 2

[0043] A preparation method of a nitrogen-doped porous vertical graphene nanowall array, comprising the following steps:

[0044] (1) Activate the carbon cloth and prepare the nickel hydroxide precursor growth solution, cut the carbon cloth into a size of 1cm*2cm, arrange the carbon in an oven with a volume ratio of 1:1 ethanol and 30% hydrogen peroxide solution and heat it to 60 ℃ for 24 hours to obtain activated carbon cloth. The nickel hydroxide precursor growth solution formula is a mixed solution of 0.15M / L nickel chloride hexahydrate and 0.3M / L hexamethylenetetramine.

[0045] (2) The activated carbon is placed in the nickel hydroxide precursor growth solution, heated to 100° C. in an oven for 10 hours to grow nickel hydroxide to obtain a nickel hydroxide / carbon cloth composite.

[0046] (3) The obtained nickel hydroxide / carbon is arranged in the mixed solution of dopamine hydrochloride-Tris, the concentration of Tris is 1.21g / L, the concentration range of dopamine hydr...

Embodiment 3

[0051] A preparation method of a nitrogen-doped porous vertical graphene nanowall array, comprising the following steps:

[0052] (1) Activate the carbon cloth and prepare the nickel hydroxide precursor growth solution, cut the carbon cloth into a size of 1cm*2cm, arrange the carbon in an oven with a volume ratio of 1:1 ethanol and 30% hydrogen peroxide solution and heat it to 60 ℃ for 24 hours to obtain activated carbon cloth. The nickel hydroxide precursor growth solution formula is a mixed solution of 0.15M / L nickel chloride hexahydrate and 0.3M / L hexamethylenetetramine.

[0053] (2) The activated carbon is placed in the nickel hydroxide precursor growth solution, heated to 100° C. in an oven for 10 hours to grow nickel hydroxide to obtain a nickel hydroxide / carbon cloth composite.

[0054] (3) The obtained nickel hydroxide / carbon is arranged in the mixed solution of dopamine hydrochloride-Tris, the concentration of Tris is 1.21g / L, the concentration range of dopamine hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com