Bacillus coagulans and its use in preparation of L-lactic acid

A technology of Bacillus coagulans and Bacillus coagulans, which is applied in the application field of Bacillus coagulans and its production of L-lactic acid by fermenting lignocellulose, which can solve problems such as application limitations and output to be improved, and reduce production costs and bacteria pollution The effect of low probability and high fermentation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Isolation and screening of embodiment 1 bacterial strain

[0026] The culture medium used in the experiment process is as follows:

[0027] Enrichment medium: Each liter of medium contains 10g of xylose, 10g of yeast powder, and the rest is distilled water, pH 6.0, sterilized at 115°C for 20min.

[0028] Fermentation medium: Each liter of medium contains 50g of xylose, 10g of yeast powder, and the rest is distilled water, pH 6.0, sterilized at 115°C for 20min.

[0029] Growth medium: Each liter of medium contains 30g of xylose, 10g of yeast powder, CaCO 3 10g, 15-20g agar powder, pH 6.5, sterilized at 115°C for 20min.

[0030] Seed medium: Each liter of medium contains 50g of glucose, 10g of yeast powder, and CaCO 3 20g, the rest is distilled water, pH 6.5, sterilized at 115°C for 20min.

[0031] Treatment medium: gas-exploded corn stalk hydrolyzate 100-150ml, yeast powder 10g, CaCO 3 30g, pH6~7, sterilized at 115°C for 20min.

[0032] Collect compost samples fr...

Embodiment 2

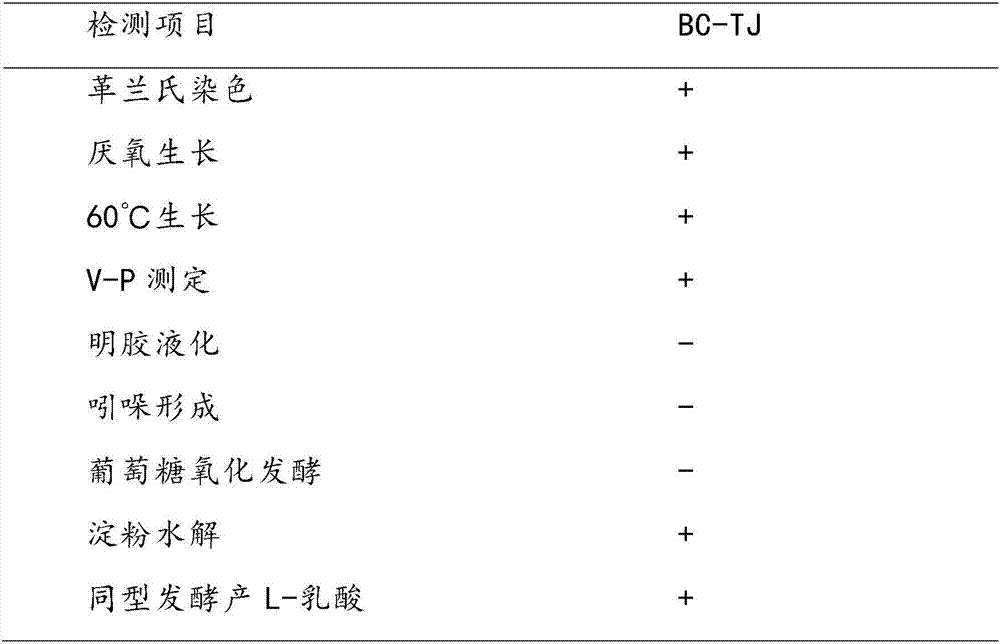

[0034] Colony Morphological Characteristics and Physiological and Biochemical Characteristics of Example 2 Bacterial Strain BC-TJ

[0035] After the strain BC-TJ was inoculated on the growth medium and grown for 24 hours, it was observed that the colony was round, with a smooth surface, milky white, and smooth edges. Gram staining was positive, the cell shape was rod-shaped, the cell size was (0.7-0.9)×(3-5) μm, and endophytic spores. The suitable growth temperature of the strain is 30°C-60°C, and the optimum growth pH is 5.5-6.5. In physiological and biochemical tests, gelatin liquefaction, indole test and glucose fermentation gas production are negative; starch hydrolysis and V.P tests are positive, and can grow under both aerobic and anaerobic conditions at 60°C. See Table 1 for specific experimental results.

[0036] Table 1 Physiological and biochemical experiment results of strain BC-TJ

[0037]

[0038] Note: "+" means positive; "-" means negative.

Embodiment 3

[0039] 16S rDNA sequence analysis of Example 3 bacterial strain BC-TJ

[0040] In order to identify the isolated strain BC-TJ more accurately, the 16S rDNA sequence of the strain BC-TJ was amplified and compared. Firstly, the genomic DNA of the strain BC-TJ was extracted, which was used as a template for 16S rDNA sequence amplification.

[0041] The strain BC-TJ that was cultured overnight was collected by centrifugation at 12,000 rpm at room temperature for 1 min, and the bacterial DNA was extracted using a bacterial DNA extraction kit (Tiangen Biochemical Technology (Beijing) Co., Ltd.), according to the instructions.

[0042] 16S rDNA sequence amplification primers:

[0043] 27f: 5'-AGAGTTTGATCCTGGCTCAG-3'

[0044] 1492r: 5'-GGYTACCTTACGACTT-3'

[0045] Reaction conditions: pre-denaturation at 95°C for 5 min; denaturation at 5°C for 30 s, annealing at 54°C for 30 s, extension at 72°C for 1 min, a total of 35 cycles; and extension at 72°C for 10 min.

[0046] Reaction syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com