Method for preparing nitrogen doped graphene aerogel through modification of plant extract

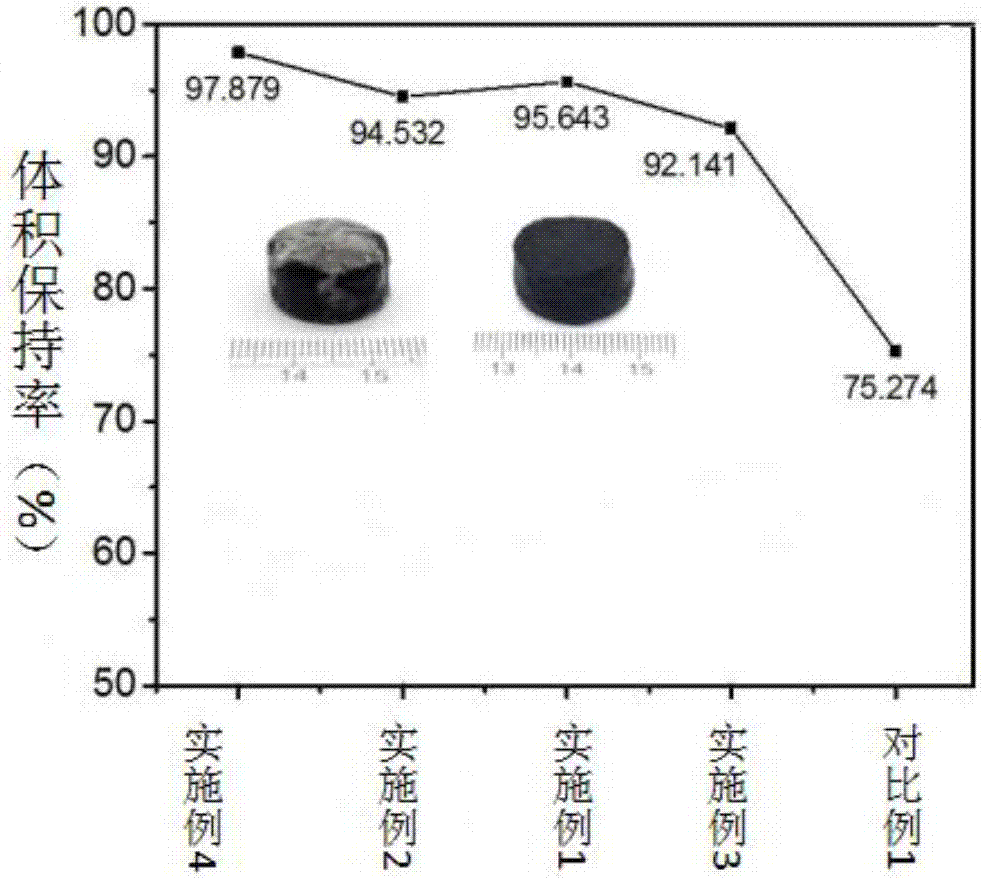

A nitrogen-doped graphene, plant extract technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of unstable structure and shape deformation of nitrogen-doped graphene aerogels, and achieve large-scale Large-scale production, convenient operation, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method utilizing plant extract modification to prepare nitrogen-doped graphene airgel, comprising the following steps:

[0039] Step 1, take 6mL of 10mg / L graphene oxide solution and 4mL of concentrated ammonia water and stir, then add 60mg of urea and 3mL of 0.3g / mL P. chinensis plant extract, stir, and ultrasonically disperse to obtain a mixed material liquid; The power is 800W, and the ultrasonic frequency is 35KHz;

[0040]Step 2. Move the mixed material liquid to a high-pressure reactor with a Teflon lining, and react at a temperature of 180° C. for 12 hours to obtain a hydrogel;

[0041] Step 3, pre-cool the hydrogel at -17°C for 12 hours after dialysis, take it out and dry it naturally to obtain nitrogen-doped graphene airgel; the dialysate used in the dialysis is ethanol aqueous solution with a concentration of 1%. , The dialysis time is 6h.

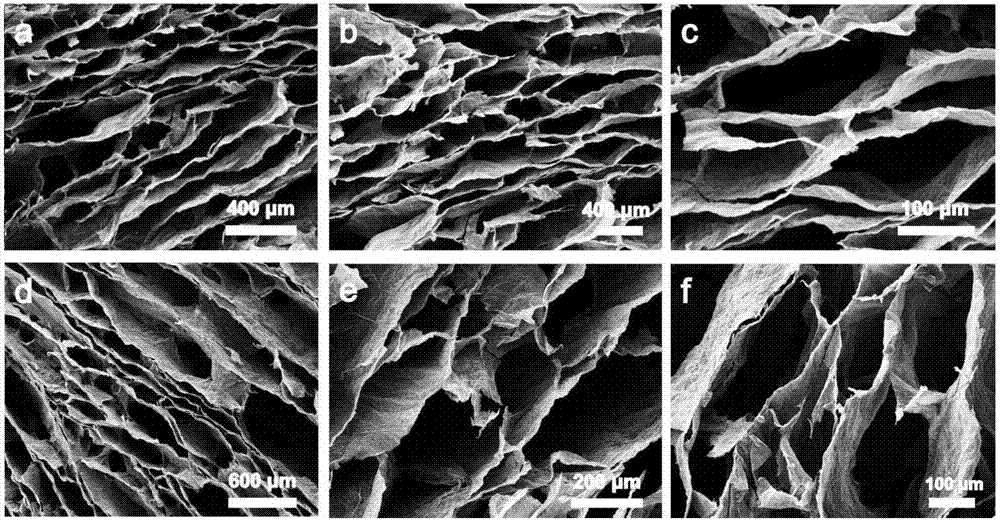

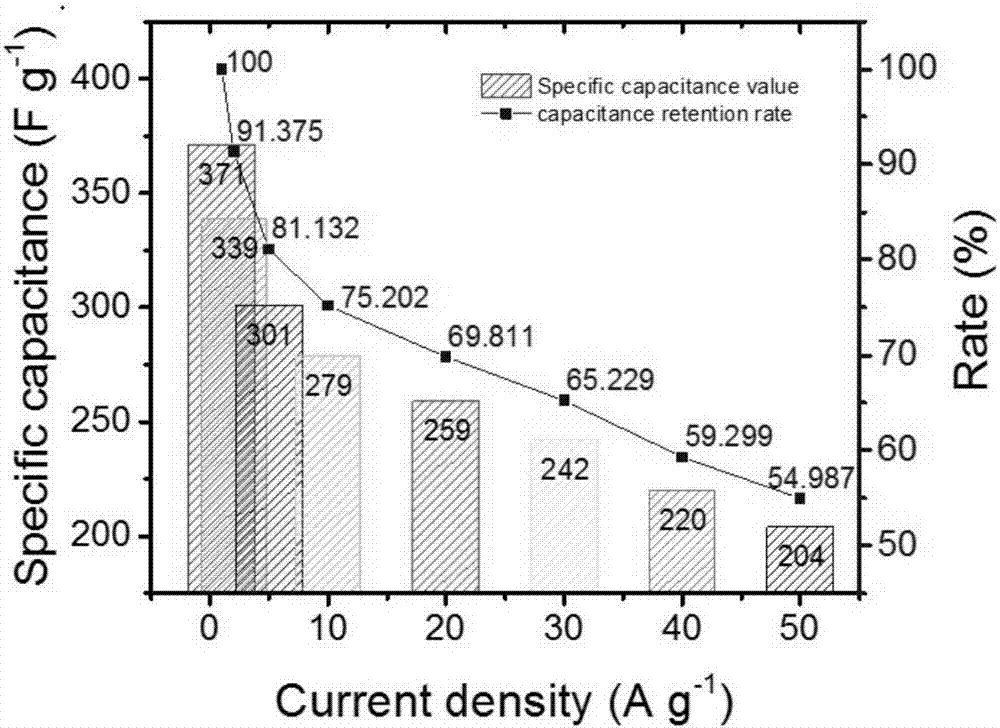

[0042] figure 2 (a-f) shows the SEM picture of the nitrogen-doped graphene airgel that embodiment 1 prepares; It c...

Embodiment 2

[0047] A method utilizing plant extract modification to prepare nitrogen-doped graphene airgel, comprising the following steps:

[0048] Step 1, take 6mL of 10mg / L graphene oxide solution and 4mL of concentrated ammonia water and stir, then add 60mg of urea and 1mL of 0.3g / mL P. chinensis plant extract, stir, and ultrasonically disperse to obtain a mixed material liquid; The power is 800W, and the ultrasonic frequency is 35KHz;

[0049] Step 2. Move the mixed material liquid to a high-pressure reactor with a Teflon lining, and react at a temperature of 180° C. for 12 hours to obtain a hydrogel;

[0050] Step 3, pre-cool the hydrogel at -17°C for 12 hours after dialysis, take it out and dry it naturally to obtain nitrogen-doped graphene airgel; the dialysate used in the dialysis is ethanol aqueous solution with a concentration of 1%. , The dialysis time is 6h.

Embodiment 3

[0052] A method utilizing plant extract modification to prepare nitrogen-doped graphene airgel, comprising the following steps:

[0053] Step 1, take 4mL of 10mg / L graphene oxide solution and 4mL of concentrated ammonia water and stir, then add 60mg of urea and 5mL of 0.3g / mL P. chinensis plant extract, stir, and ultrasonically disperse to obtain a mixed material liquid; The power is 800W, and the ultrasonic frequency is 35KHz;

[0054] Step 2. Move the mixed material liquid to a high-pressure reactor with a Teflon lining, and react at a temperature of 180° C. for 12 hours to obtain a hydrogel;

[0055] Step 3, pre-cool the hydrogel at -17°C for 12 hours after dialysis, take it out and dry it naturally to obtain nitrogen-doped graphene aerogel; the dialysate used in the dialysis is ethanol aqueous solution with a concentration of 5% , The dialysis time is 6h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com