Textile fabric singeing and printing production line

A textile fabric and production line technology, applied in the field of singeing equipment, can solve problems such as difficulty in shaping, inaccurate shaping, and irregular pattern production efficiency, and achieve the effects of convenient shaping, good effect, and improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

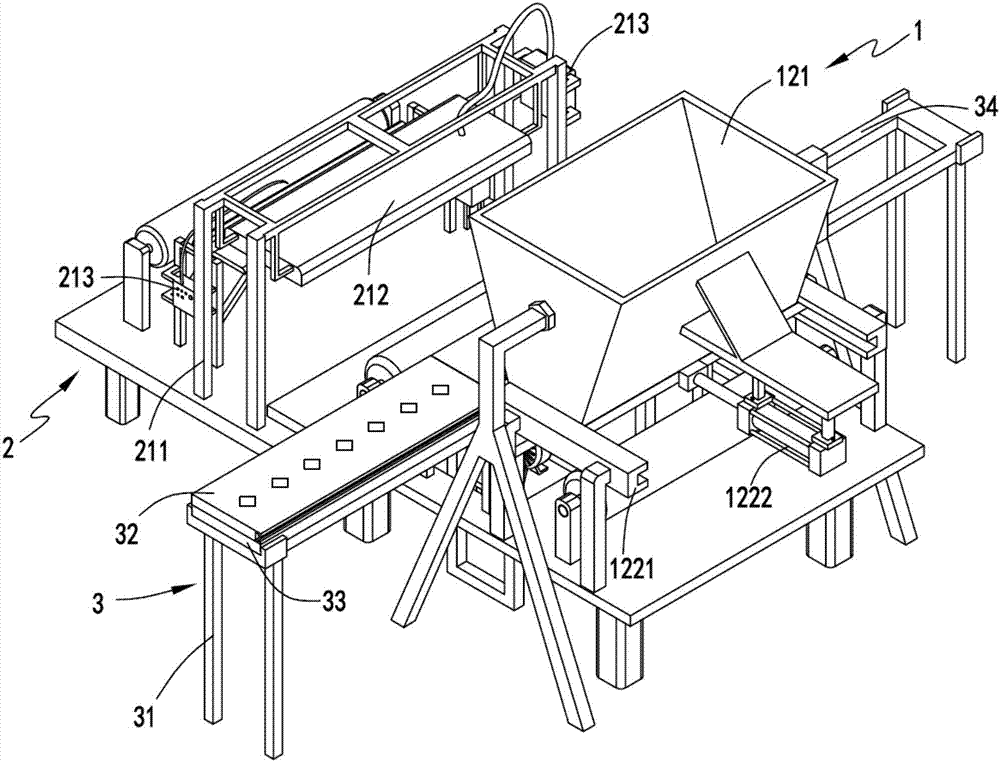

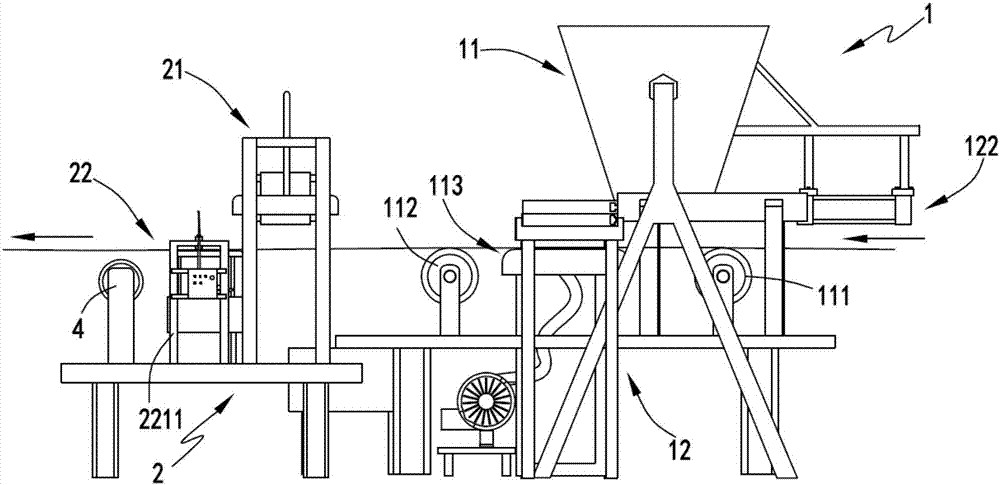

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11As shown, a textile fabric singeing printing production line includes a shaping part 1, and the shaping part 1 is used to put metal particles into the hair gap on the surface of the cloth according to the shape of the cloth to be embossed, and the shaping part 1 includes a The supporting adsorption mechanism 11 below the cloth and the upper metal particle mechanism 12 arranged above the cloth; include an adsorption hot stamping mechanism 2, which is arranged at the rear end of the shaping part 1, and the adsorption hot stamping mechanism 2 includes A magnetic mechanism 21 for absorbing metal particles on the cloth and a singeing mechanism 22 arranged on the rear side of the magnetic mechanism 21 for burning off the hairs erected under the action of the magnetic mechanism 21.

[0041] Through the cooperation of the transfer ...

Embodiment 2

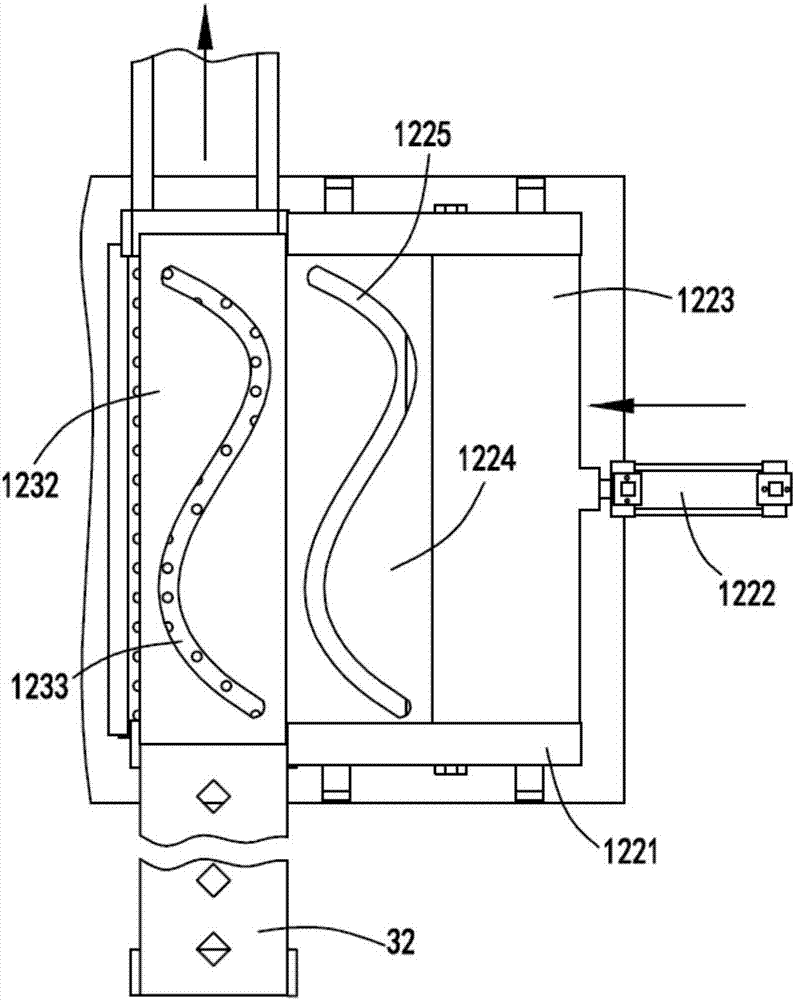

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is: further, the negative pressure adsorption device 113 includes an adsorption plate 1131 arranged directly below the discharge device 123 and attached to the lower surface of the textile fabric, and communicates with the interior of the adsorption plate 1131 The negative pressure machine 1132, the surface of the adsorption plate 1131 is provided with a number of adsorption holes 1133.

[0057] Negative pressure suction is carried out to the lower surface of the fabric by arranging a negative pressure adsorption device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com