A kind of preparation method of medicinal glacial acetic acid

A technology of glacial acetic acid and copper sulfate, applied in the separation/purification of carboxylic acid compounds, can solve the problems of high energy consumption, low acetic acid purity, low volatility, etc., and achieve production cost savings, good oxidation effect, and product purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

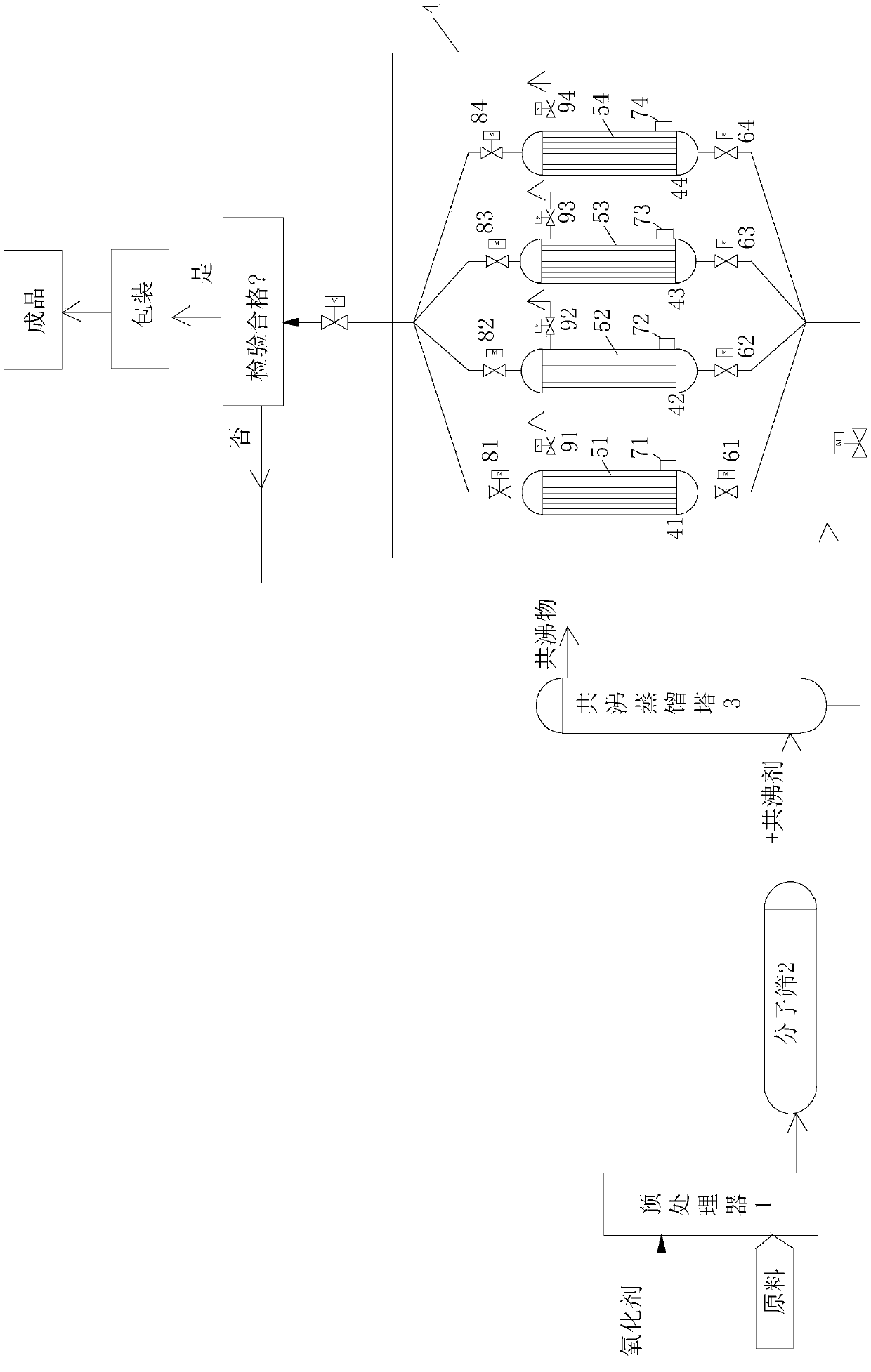

[0032] The preparation method of the medicinal glacial acetic acid of the present embodiment, its flow process is as follows figure 1 shown, including the following steps:

[0033] (1) Take 10kg of raw material industrial acetic acid and place it in preprocessor 1, and add 500g of oxidizing agent hydrogen peroxide to obtain oxidation product;

[0034] (2) the oxidized product is passed through molecular sieve 2, and the adsorption time is 20min to obtain impurity-removing product, and molecular sieve 2 selects 400g of ZSM-5 molecular sieve;

[0035] (3) The impurity removal product enters the azeotropic rectification tower 3 together with the entrainer, and the entrainer is selected from 500 g of butyl acetate, and the tower top temperature is controlled at 70 to 75 ° C, and the azeotrope of water and butyl acetate is distilled from the tower top Go out, collect bottom product and be primary glacial acetic acid;

[0036](4) The primary glacial acetic acid is passed into the ...

Embodiment 2

[0043] The preparation method of the medicinal glacial acetic acid of the present embodiment may further comprise the steps:

[0044] (1) Take by weighing 10kg of raw material industrial acetic acid and place it in the preprocessor, and add oxidant hydrogen peroxide 100g to obtain the oxidation product;

[0045] (2) the oxidation product is passed through a molecular sieve, the adsorption time is 30min, and the impurity product is obtained, and the molecular sieve 2 selects 600g of ZSM-5 molecular sieve;

[0046] (3) The impurity-removed product enters the azeotropic rectification tower together with the entrainer. The entrainer is 20kg of butyl acetate, operated under normal pressure, the temperature at the top of the tower is controlled at 70-75°C, the temperature at the bottom of the tower is 100-118°C, water and The azeotrope of butyl acetate distills off from the top of the tower, and the bottom product of the collection is primary glacial acetic acid;

[0047] (4) Pass ...

Embodiment 3

[0054] The preparation method of the medicinal glacial acetic acid of the present embodiment, its flow process is as follows figure 1 shown, including the following steps:

[0055] (1) Take 10kg of raw material industrial acetic acid and place it in the preprocessor 1, and add oxidant hydrogen peroxide 200g to obtain the oxidation product;

[0056] (2) the oxidized product is passed through molecular sieve 2, and the adsorption time is 25min to obtain impurity-removing product, and molecular sieve 2 selects 500g of ZSM-5 molecular sieve;

[0057] (3) impurity removal product and entrainer enter azeotropic rectification tower 3 together, entrainer selects isopropyl acetate 1kg for use, normal pressure operation, tower top temperature is controlled at 64~80 ℃, tower still temperature 100~118 ℃, The azeotrope of water and isopropyl acetate distills off from the top of the tower, and the bottom product of the collection is primary glacial acetic acid;

[0058] (4) The primary gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com