Thiadiazole derivative for vulcanized cross-linking of halogen-containing polymer

A technology of thiadiazole derivatives, vulcanization and cross-linking, which is applied in the direction of organic chemistry, can solve the problems of difficult post-processing, poor comprehensive performance of rubber products, and low yield of products, and achieve simplified post-processing operations and improved mechanical properties. Excellent, easy process control effect

Inactive Publication Date: 2011-06-15

烟台恒鑫化工科技有限公司

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Foreign countries have also started research on the vulcanization of halogen-containing rubber very early. Hercules Corporation of the United States has developed mercaptothiadiazole compounds, and Nakamura and others in Japan have developed trimercaptotriazine derivatives for the crosslinking of halogen-containing rubber. Both vulcanizing agents have disadvantages: although the vulcanization speed of mercaptothiadiazole compound is fast, the anti-scorch performance is not good, and the vulcanization speed of trimercaptotriazine compound is too slow

However, the use of oxidizing agents (hydrogen peroxide) in the production of this type of vulcanizing agent increases the danger in the production process, and due to the use of oxidizing agents, the mercapto groups of 2,5-dimercapto-1,3,4-thiadiazole (DMTD) It is easy to be oxidized to dimer or polymer compound. The viscosity of the product is very high during post-treatment, which is not conducive to the separation and purification of the product. The yield of the product is very low or even the target product cannot be obtained. The conditions for the reaction are strict. A slight difference in the process will generate a large amount of resinous by-products, making the post-processing of the product very difficult, which is not conducive to the realization of industrialization

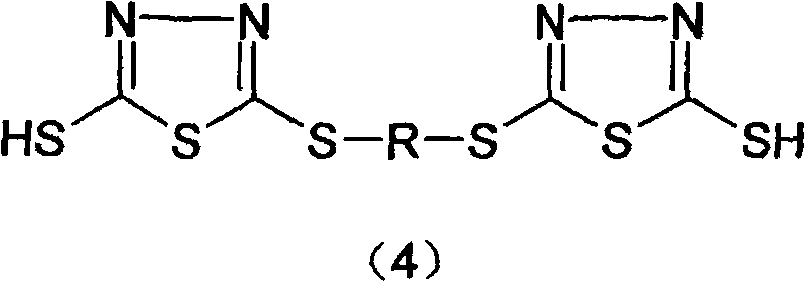

2. In U.S. Patent No. 5,849,925, it is introduced that a compound of structural formula (4) can also be used for vulcanization and crosslinking of halogen-containing rubber, but this type of compound also needs to use an oxidant during production, and the control of reaction conditions is also The requirements are relatively strict, which is not conducive to the realization of industrialization

3. In Chinese patent 200610004725.3, a novel compound of structural formula (5) is introduced: bis-DMTD, which is a derivative of DMTD, can be used in lubricating oil as an extreme pressure and anti-wear additive, but has not yet been seen There are reports that bis-DMTD can be used as a vulcanizing agent in halogenated rubber

4. In Japanese Patent Laid-Open No. 61-238,838 (1986), the compound of structural formula (6) is reported: poly 2,5-dimercapto-1,3,4-thiadiazole, which can be used for vulcanization containing Halogen rubber, such as chlorinated polyethylene rubber (CPE, CM), neoprene rubber (CR), epichloroether rubber (ECO), works well as a vulcanizing agent, but it is introduced in the patent to produce poly 2,5 - Dimercapto-1,3,4-thiadiazole should use oxidizing agent (hydrogen peroxide). If the speed is too fast during hydrogen peroxide dropwise addition, the reaction will be intense and violently exothermic. floc, which affects the yield of the product, so this method is also unfavorable for realizing industrialization

5. In Japanese Patent Laid-Open No. 54-58, 750 (1979), it was mentioned that 2,5-dimercapto-1,3,4-thiadiazole can be used for vulcanization and crosslinking of chlorinated polyethylene (CPE) rubber, However, the overall performance of rubber products is poor

6. EurpatAppl.Ep78, 155 (1983) reported that polymercapto compounds-thiadiazoles can be used for vulcanization and crosslinking of chlorinated polyethylene rubber (CPE), but did not introduce the production method of mercapto-thiadiazoles

In a word, there are no reports or studies on the industrial production of thiadiazole derivatives used for vulcanization and crosslinking of halogen-containing polymers in China so far.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a thiadiazole derivative for vulcanized cross-linking of a halogen-containing polymer. The structural formula of the thiadiazole derivative is shown in a formula (1) or (2), wherein R is aryl group or C1-17alkyl group. The thiadiazole derivative for the vulcanized cross-linking of the halogen-containing polymer can be used as a vulcanized agent.

Description

Thiadiazole Derivatives for Vulcanization and Crosslinking of Halogenated Polymers This application is a divisional application of "Application No. 200710016228.X, filing date: 2007.7.26. The title of the invention is Thiadiazole Derivatives for Vulcanization and Crosslinking of Halogen-Containing Polymers and its Synthetic Method". technical field The present invention relates to a thiadiazole derivative and a synthesis method thereof, in particular to a thiadiazole derivative of structural formula (1) or (2) which can be used for vulcanization and crosslinking of halogen-containing polymers, especially halogen-containing rubber, and a synthesis method thereof . Wherein: the R group in the above structural formula is: an aryl group or a C1-17 alkyl group. Background technique Halogen-containing polymers include halogen-containing rubber, halogen-containing plastics, rubber-plastic blend materials, etc. Among them, halogen-containing rubber is an important part of spe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07D285/125

Inventor 张玉

Owner 烟台恒鑫化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com