Automatic conveying equipment for circular floating beds special for restoring aquatic ecosystem

An ecological system and conveying equipment technology, applied in the direction of manual conveying devices, transportation and packaging, etc., can solve the problems of complex operation, low work efficiency and high labor intensity of circular floating beds, so as to improve stability, improve efficiency and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

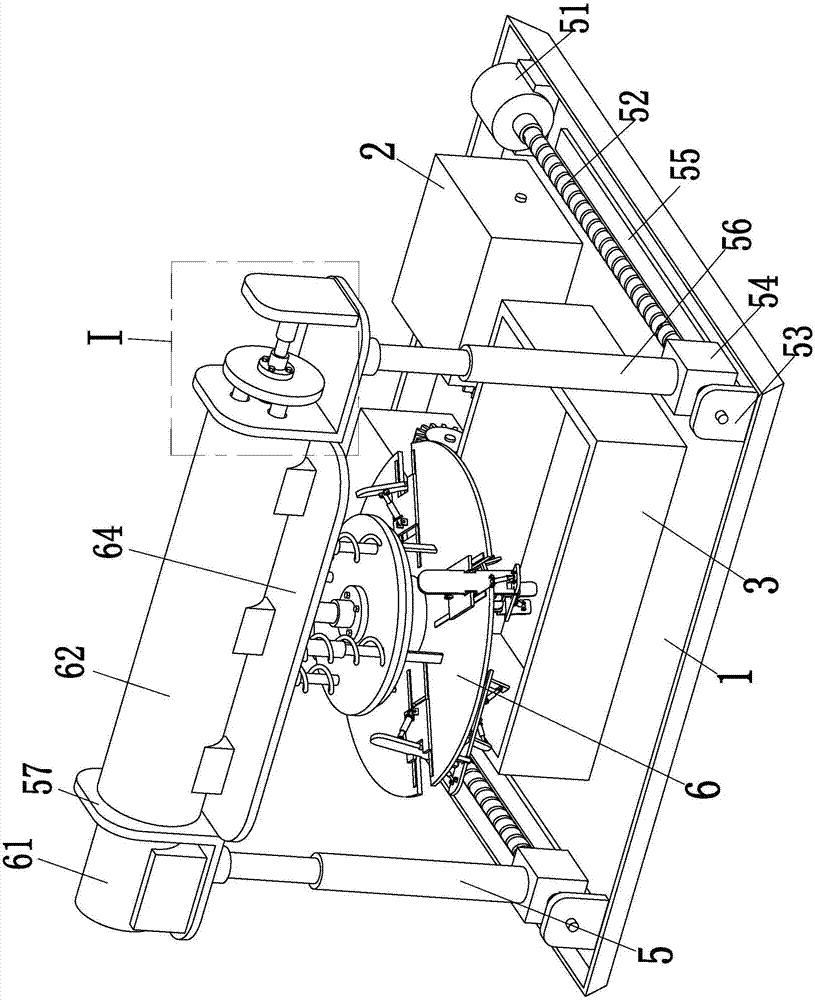

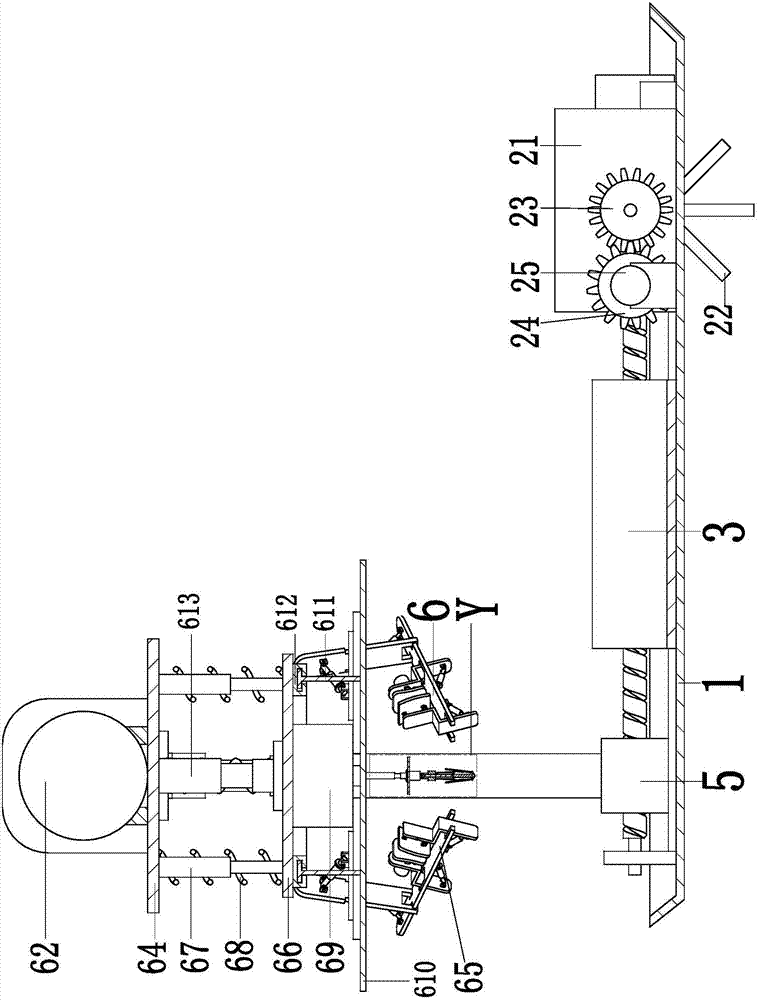

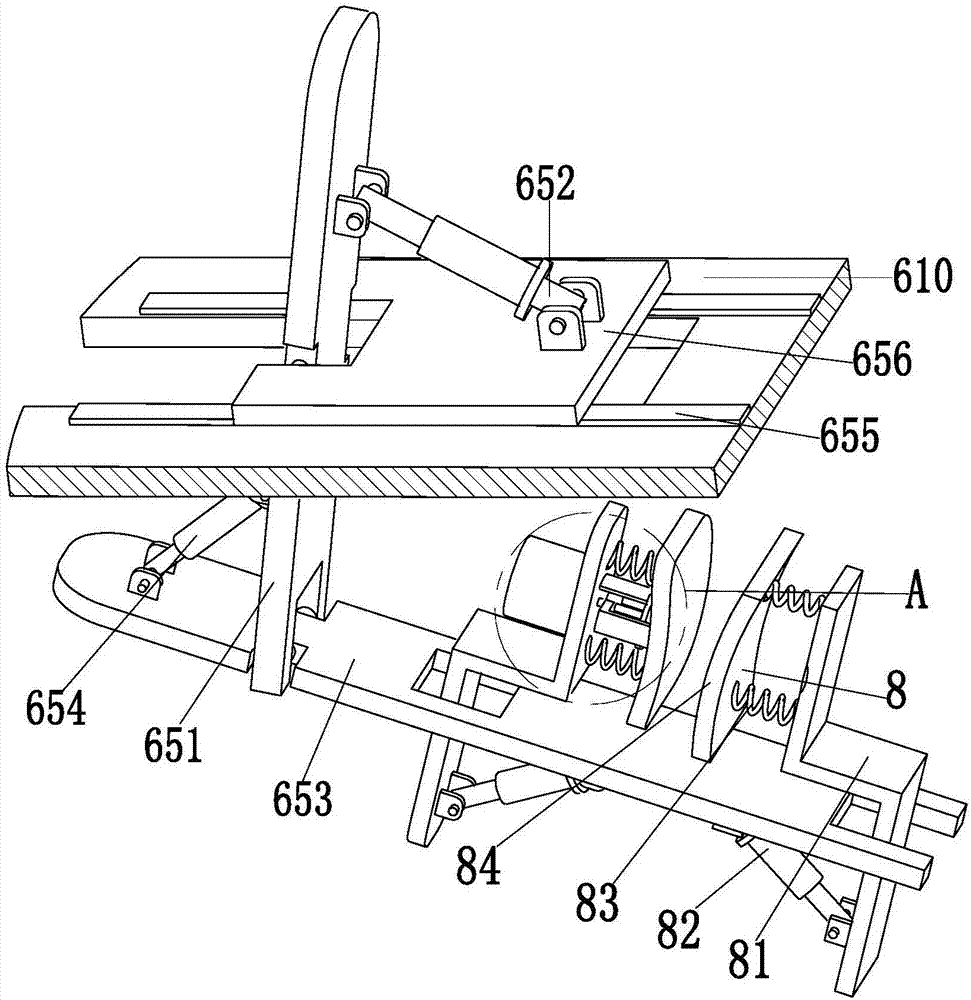

[0026] Such as Figure 1 to Figure 6 As shown, an automatic conveying device for a special circular floating bed for repairing water ecosystems includes a hull 1, and two working tanks are arranged symmetrically at the rear end of the hull 1, and a power device 2 is arranged in each working tank, and two The two power devices 2 in the working tank can drive the hull 1 to move freely. The middle part of the hull 1 is equipped with a placement frame 3, and a circular floating bed is placed in the placement frame 3. Two mobile lifting devices are symmetrically installed on the left and right sides of the hull 1. 5. A grasping and pushing device 6 is installed between the two mobile lifting devices 5. The two moving lifting devices 5 can drive the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com