Water-soluble salt core and preparation method thereof

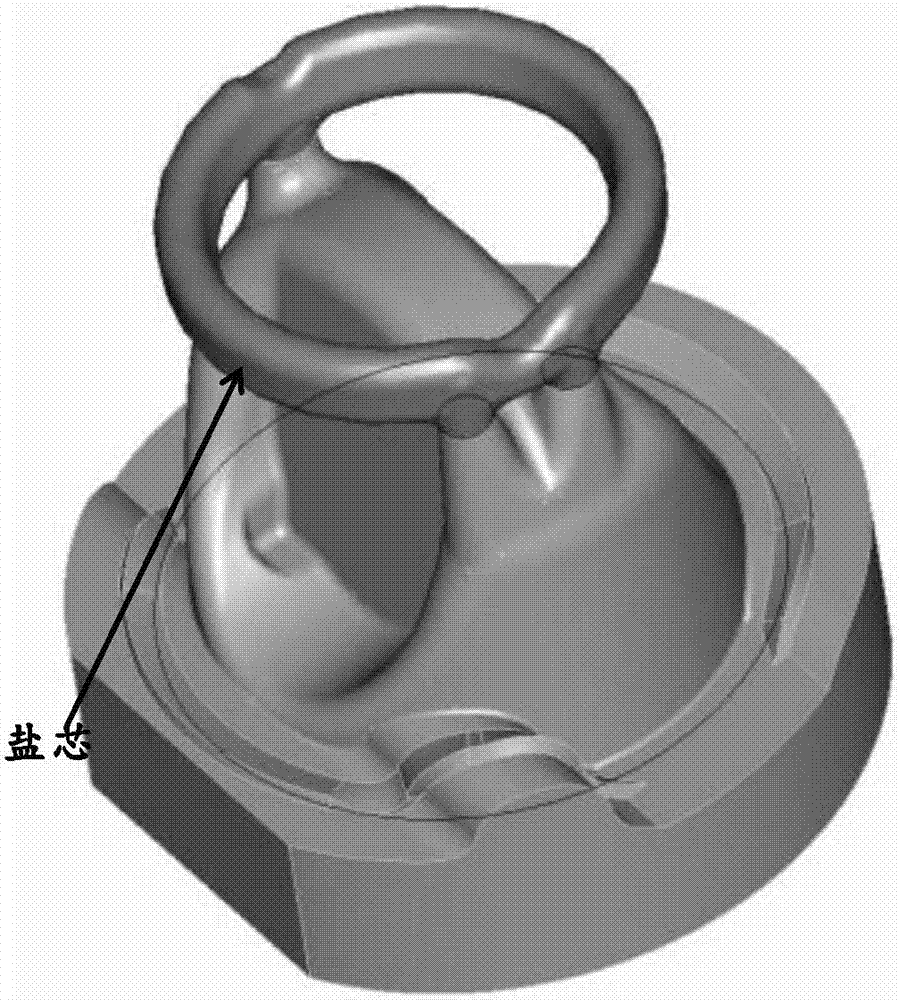

A technology of water-soluble salt and salt core, which is applied to cores, manufacturing tools, casting and molding equipment, etc., can solve the problems of large fluctuation in the strength of composite salt cores, increase in harmful gas emissions, and reduce the service life of pistons, so as to meet the strength requirements. requirements, improved particle size distribution, easy dissolving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a kind of preparation method of water-soluble salt core, comprises the following steps:

[0043] a) ball milling, sieving and baking the salt powder in sequence to obtain the salt core material;

[0044] b) Sequentially pressing and sintering the salt core material obtained in step a) to obtain a water-soluble salt core.

[0045] In the invention, firstly, the salt powder is ball milled, screened and baked in order to obtain the salt core material. In the present invention, the salt powder is preferably refined industrial salt and / or refined edible salt; wherein NaCl≥92%. In the present invention, the source of the salt powder is not particularly limited, and the above-mentioned commercially available refined industrial salt and refined edible salt well known to those skilled in the art can be used.

[0046]In the invention, firstly, the salt powder is ball-milled to obtain the ball-milled salt powder. In the present invention, the equipment fo...

Embodiment 1

[0068] (1) Pour 100kg of dry salt powder into an 800×1400 ceramic ball mill. The material of the ball is pebbles, and the loading amount is 500kg / time. Ball mill for 5 minutes at a speed of 33r / min (cylinder) to obtain milled salt pink;

[0069] (2) sieve the salt powder after ball milling to obtain the sieved salt powder; the sieve hole size / mesh number comparison table used for the sieving is shown in Table 1;

[0070] Table 1 Sieve hole size / mesh number comparison table used for sieving

[0071] Screen No.(#)

mesh number

Mesh hole size / um

1

230

62

2

180

80

3

170

90

4

115

150

5

80

180

6

60

250

7

42

355

8

32

500

9

24

700

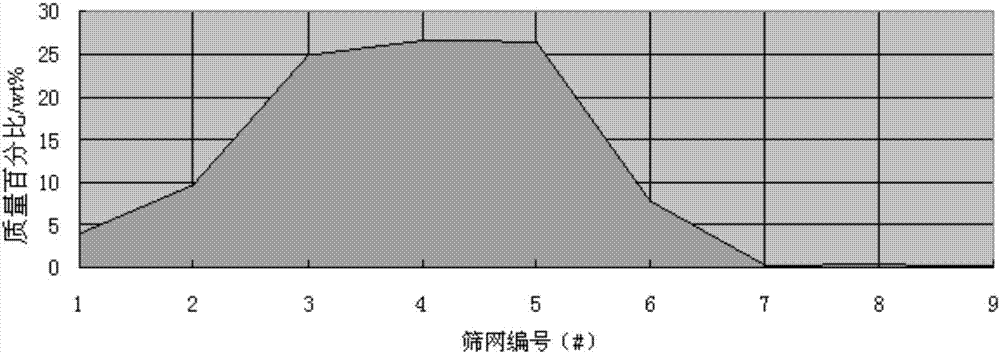

[0072] The particle size distribution of the salt powder after the sieving is as follows: image 3 As shown, specifically:

[0073] Less than 62 μm accounted for 3.90 wt%, less than 80 μm and greater than or equal to 62 μm acc...

Embodiment 2

[0080] The preparation method provided in Example 1 was used to prepare water-soluble salt core products, the difference being that the ball milling time described in step (1) was 1 min;

[0081] The powdered salt after the ball milling is sieved to obtain the powdered salt after the sieving; the particle size distribution of the powdered salt after the sieving is as follows: Figure 6 As shown, specifically:

[0082] Less than 62 μm accounts for 0.57 wt%, less than 80 μm and greater than or equal to 62 μm accounts for 2.38 wt%, less than 90 μm and greater than or equal to 80 μm accounts for 15.99 wt%, less than 150 μm and greater than or equal to 90 μm accounts for 24.87 wt%, less than 180 μm and greater than or equal to 150 μm accounts for 45.41 wt%, less than 250 μm greater than Equal to 180 μm accounts for 9.74 wt%, less than 355 μm and greater than or equal to 250 μm accounts for 0.19 wt%, less than 500 μm and greater than or equal to 355 μm accounts for 0.40 wt%, and les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com