Cathode active material for lithium ion battery, method for preparing cathode active material and cathode and battery with cathode active material

A negative electrode active material, lithium ion battery technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of cracking and falling off of the outer layer silicon carbon material, avoid cracking and pulverization, avoid Contact surface cracking and peeling, the effect of alleviating volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a lithium ion battery negative electrode, the negative electrode includes a negative electrode current collector and a negative electrode active material, the negative electrode active material includes a negative electrode active material, a negative electrode binder, and the negative electrode active material can also optionally include a negative electrode conductive agent, The negative electrode conductive agent is a conventional negative electrode conductive agent in the field; the preparation method of the negative electrode is a conventional lithium ion battery negative electrode preparation method in the field, including the negative electrode slurry obtained by mixing the negative electrode active material, the negative electrode binder, etc. with an organic solvent material coating and drying on the negative electrode current collector, the negative electrode current collector is a negative electrode current collector conventionall...

Embodiment 1

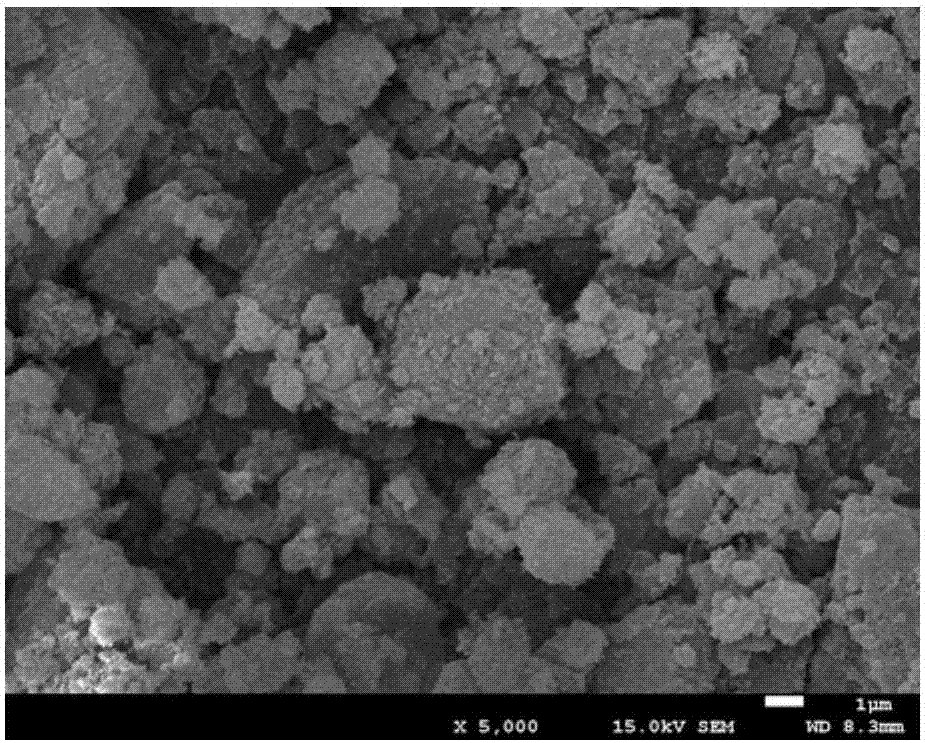

[0049] Step 1. Select nano-silicon with a particle size of 30nm and asphalt for ball milling (the ball milling process was carried out under a nitrogen atmosphere in the experiment, and no special instructions will be made later) to disperse. The mass ratio of nano-silicon and asphalt is 1:4, and the ball milling time is 2h , ball milling speed 250r / min. Under a nitrogen atmosphere, the temperature was raised at 5°C / min, and calcined at 500°C for 4h. After 210r / min, 1h ball milling. The particle size of the obtained silicon-carbon composite particles is 0.1 μm, which is marked as A1.

[0050] Step 2. Heat the asphalt to 100°C to turn the asphalt into a liquid state, add A1, the mass ratio of A1 to asphalt is 1:3, knead and stir at 100°C for 1 hour. After it is taken out and cooled, it is crushed by a pulverizer and marked as B1.

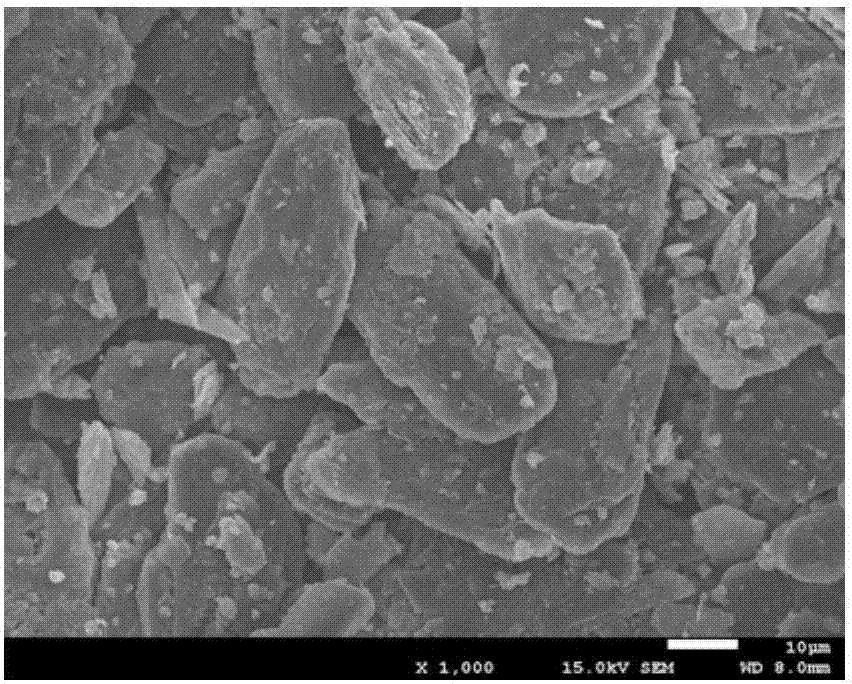

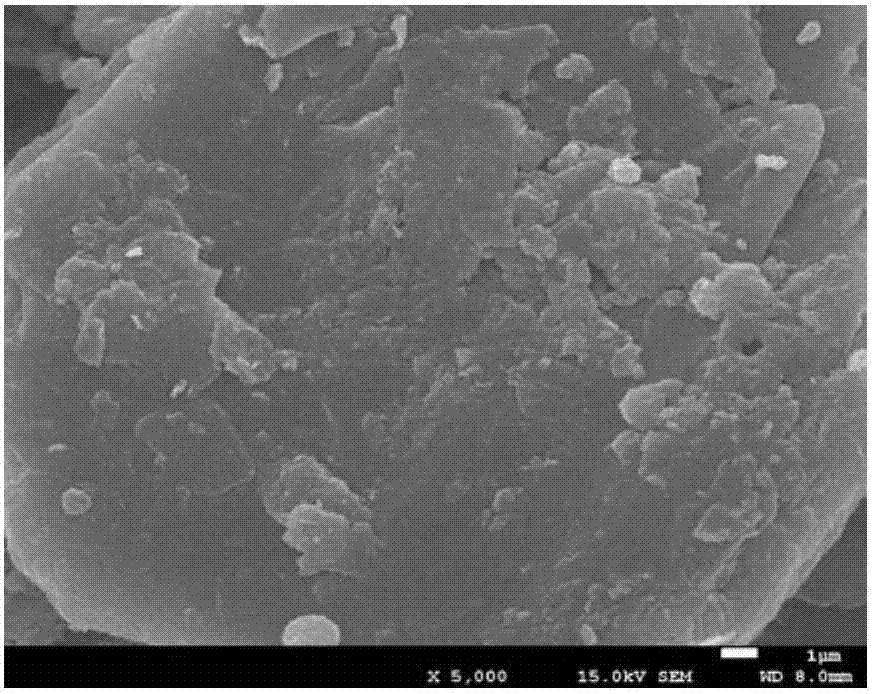

[0051] Step 3. Use a high-speed mixer at 300r / min to mix B1 and natural graphite particles with a particle size of 20um, and the ratio of B1 to g...

Embodiment 2

[0054] Step 1. Select nano-silicon with a particle size of 30nm and asphalt for ball milling (the ball milling process in the experiment was carried out under a nitrogen atmosphere, and no special instructions will be made in the follow-up). The mass ratio of nano-silicon and asphalt is 1:2, and the ball milling time is 2h , ball milling speed 250r / min. Under a nitrogen atmosphere, the temperature was raised at 5°C / min, and calcined at 500°C for 4h. After 210r / min, 1h ball milling. The particle size of the obtained silicon-carbon composite particles is 0.5 μm, which is marked as A2.

[0055] Step 2. Heat the asphalt to 100°C to turn the asphalt into a liquid state, add A2, the mass ratio of A2 to asphalt is 1:1, knead and stir at 100°C for 1 hour. After it is taken out and cooled, it is crushed by a pulverizer and marked as B2.

[0056] Step 3. Use a high-speed mixer at 300r / min to mix B2 and artificial graphite particles with a particle size of 12um, and the ratio of B2 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com