MnO2-porous polyaniline composite electrode as well as preparation method and application thereof

A manganese dioxide and composite electrode technology, which is applied in the field of electrochemistry, can solve the problems of difficult and precise control of the content, and achieve the effects of high overall energy density, long cycle life and optimized overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] first step

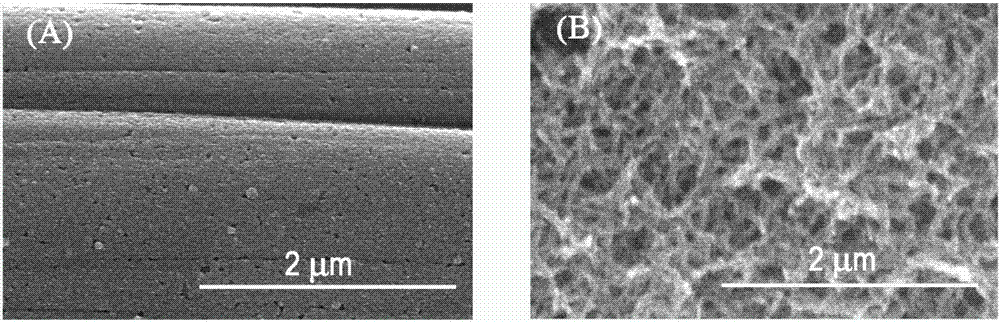

[0041] Formulated with MnSO 4 and sulfuric acid mixed aqueous solution, the concentration of manganese sulfate in the mixed solution is 0.5mol / L, and the concentration of sulfuric acid is 2mol / L. Cut the carbon paper into an area of 4×1cm 2 The carbon paper tape is used as a current collector, and the current collector is ultrasonically washed with 10% sulfuric acid aqueous solution and acetone in turn, and finally rinsed with water and dried. Use an area of 4×4cm 2 The titanium mesh electrode is the counter electrode, the above mixed solution is the electrodeposition solution, and the current collector after surface cleaning is the anode (the working area is 1×1cm 2 ), conduct constant current anodic oxidation electrodeposition, the temperature of the electrodeposition solution is 5°C, and the current density is 8mA / cm 2 , the electrodeposition time is 3 minutes. After the electrodeposition is completed, the obtained manganese dioxide / carbon compo...

Embodiment 2

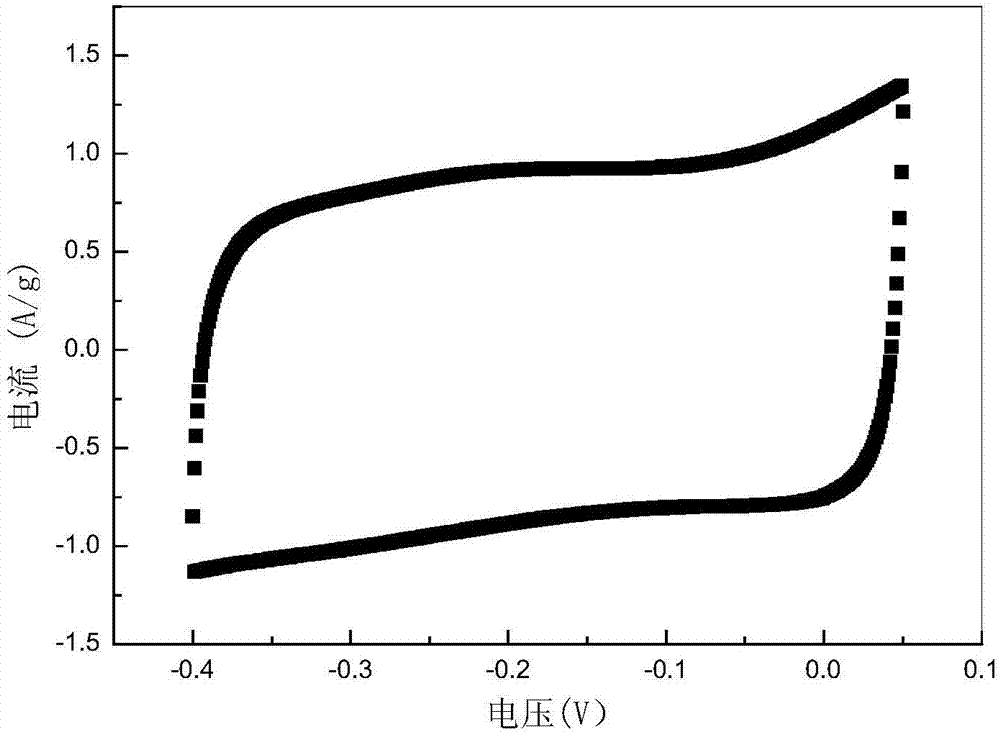

[0046] The operation process is the same as in Example 1, except that the MnSO in the manganese sulfate solution 4 and H 2 SO 4 The concentrations are 0.1mol / L and 0.5mol / L respectively, and the electrodeposition current density in the first step is 5mA / cm 2 , the electrodeposition time is 10 minutes, the concentrations of sulfuric acid and aniline sulfate in the acidified aniline sulfate solution are 0.5mol / L and 0.01mol / L respectively, and the electrolyte temperature of the first step of electrodeposition and the second step of electropolymerization are both 10°C , the potential scanning rate in the second step of electropolymerization is 100mV / s, the number of scanning segments is 20, and the measured specific capacitance of the electrode active material is 401.8F / g.

Embodiment 3

[0048] The operation process is the same as in Example 1, except that the MnSO in the manganese sulfate solution 4 and H 2 SO 4 The concentrations are 0.2mol / L and 1mol / L respectively, and the electrodeposition current density in the first step is 10mA / cm 2 , the time is 2 minutes, the concentrations of sulfuric acid and aniline sulfate in the acidified aniline sulfate solution are 1mol / L and 0.02mol / L respectively, the electrolyte temperature of the first step of electrodeposition and the second step of electropolymerization are both 10°C, the second The potential scanning rate during electropolymerization is 50mV / s, and the number of scanning segments is 10. The measured specific capacitance of the electrode active material is 436.3F / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com