Novel niobium-tungsten crucible

A niobium-tungsten crucible and crucible technology, which is applied in the field of new niobium-tungsten crucibles, can solve the problems of damage to the purity of the melt in the crucible, increase the economic burden of the enterprise, and the grain boundary is easily eroded by heat, so as to improve the chemical and mechanical stability and comprehensive performance. The effect of improving and constant temperature effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

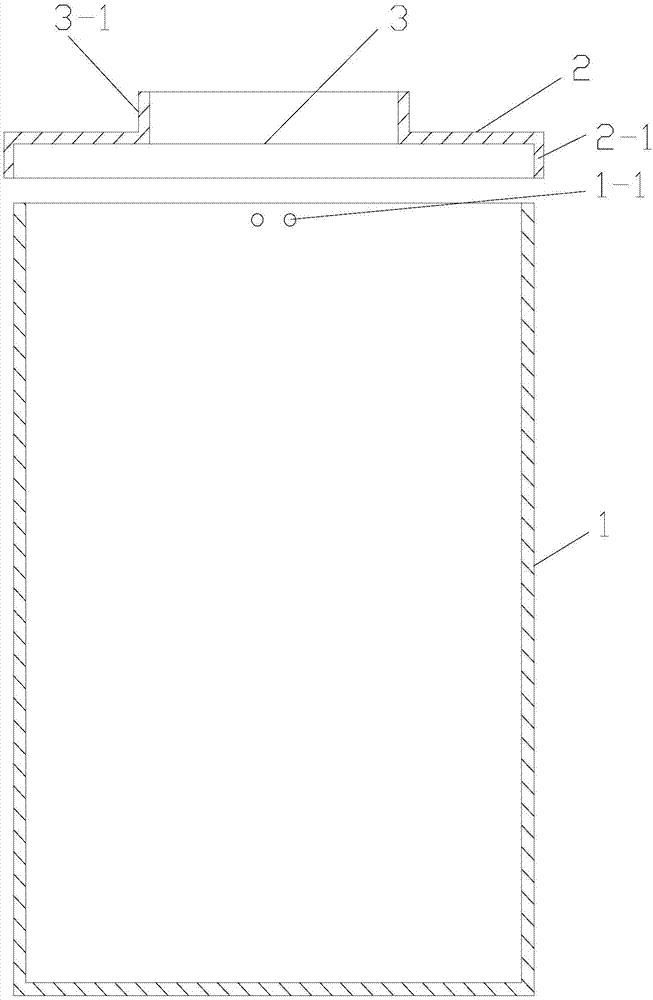

[0017] Attached below figure 1 An embodiment of the present invention is described.

[0018] The new-style niobium-tungsten crucible has a crucible body 1, and the crucible body 1 is a barrel-shaped structure made of niobium-tungsten alloy. Preferably, the barrel shape is a straight barrel shape with equal upper and lower diameters, and the barrel bottom and the barrel wall have the same thickness, By adding tungsten whose radius is similar to that of niobium atoms, it can compensate for the defects between pure niobium atoms and increase its grain density. Therefore, the high melting point metal tungsten has a solid solution strengthening effect on niobium. The pure niobium crucible is optimized into a niobium-tungsten alloy crucible. Its strength does not need to increase the wall thickness. Under the premise of saving consumables, it improves the oxidation resistance, that is, the overall chemical stability and mechanical stability, ensures the purity of the molten metal, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com