Production method of eye-protecting and radiation-resisting display protection film

A manufacturing method and radiation protection technology, applied in the direction of film/sheet adhesives, adhesive types, adhesive additives, etc., can solve problems such as damage to eyesight, eye fatigue, and inability to protect users' eyesight, and achieve improved vision. Waterproof, eye fatigue relief, eye protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

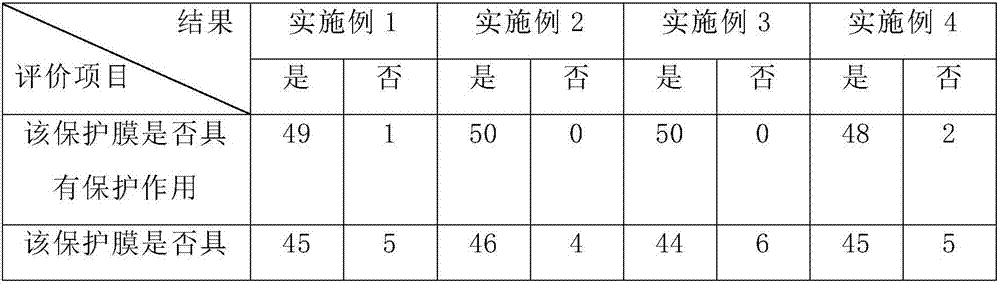

Examples

Embodiment 1

[0024] (1) Tempered glass processing: Send the high-transparency tempered glass to the precision cutting machine for cutting, cut the glass into the glass of the required size, and then send the small-sized glass to the chamfering grinding wheel, rough grinding wheel, fine grinding Chamfering and edging is performed on the grinding machine of the wheel and polishing wheel, and then the tempered glass after chamfering and grinding is sent to the cleaning machine, first pickled and then rinsed with deionized water, and dried for later use.

[0025] (2) Anti-radiation layer coating: In a clean room with a cleanliness level of 10,000, apply nano-alumina coatings and molybdenum powder coatings to the lower surface of the tempered film to form the first anti-radiation layer and the second anti-radiation layer , the thickness of the first anti-radiation layer is 15nm, the thickness of the second anti-radiation layer is 10nm, and placed horizontally for 8h in a dust-free environment to...

Embodiment 2

[0030] (1) Tempered glass processing: Send the high-transparency tempered glass to the precision cutting machine for cutting, cut the glass into the glass of the required size, and then send the small-sized glass to the chamfering grinding wheel, rough grinding wheel, fine grinding Chamfering and edging is performed on the grinding machine of the wheel and polishing wheel, and then the tempered glass after chamfering and grinding is sent to the cleaning machine, first pickled and then rinsed with deionized water, and dried for later use.

[0031] (2) Anti-radiation layer coating: In a clean room with a cleanliness level of 10,000, apply nano-alumina coatings and molybdenum powder coatings to the lower surface of the tempered film to form the first anti-radiation layer and the second anti-radiation layer , the thickness of the first anti-radiation layer is 20nm, the thickness of the second anti-radiation layer is 15nm, and placed horizontally for 10h in a dust-free environment t...

Embodiment 3

[0036] (1) Tempered glass processing: Send the high-transparency tempered glass to the precision cutting machine for cutting, cut the glass into the glass of the required size, and then send the small-sized glass to the chamfering grinding wheel, rough grinding wheel, fine grinding Chamfering and edging is performed on the grinding machine of the wheel and polishing wheel, and then the tempered glass after chamfering and grinding is sent to the cleaning machine, first pickled and then rinsed with deionized water, and dried for later use.

[0037] (2) Anti-radiation layer coating: In a clean room with a cleanliness level of 10,000, apply nano-alumina coatings and molybdenum powder coatings to the lower surface of the tempered film to form the first anti-radiation layer and the second anti-radiation layer , the thickness of the first anti-radiation layer is 17nm, the thickness of the second anti-radiation layer is 12nm, and placed horizontally for 9h in a dust-free environment to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com