A volume expandable material swelled by carbon dioxide and water, and a preparation method thereof and a method for improving CO2 huff and puff effect

A water-expanding, carbon dioxide technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of fast water-absorbing expansion and high cost of cationic monomers, reducing seepage capacity and improving oil recovery. , the effect of expanding the scope of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

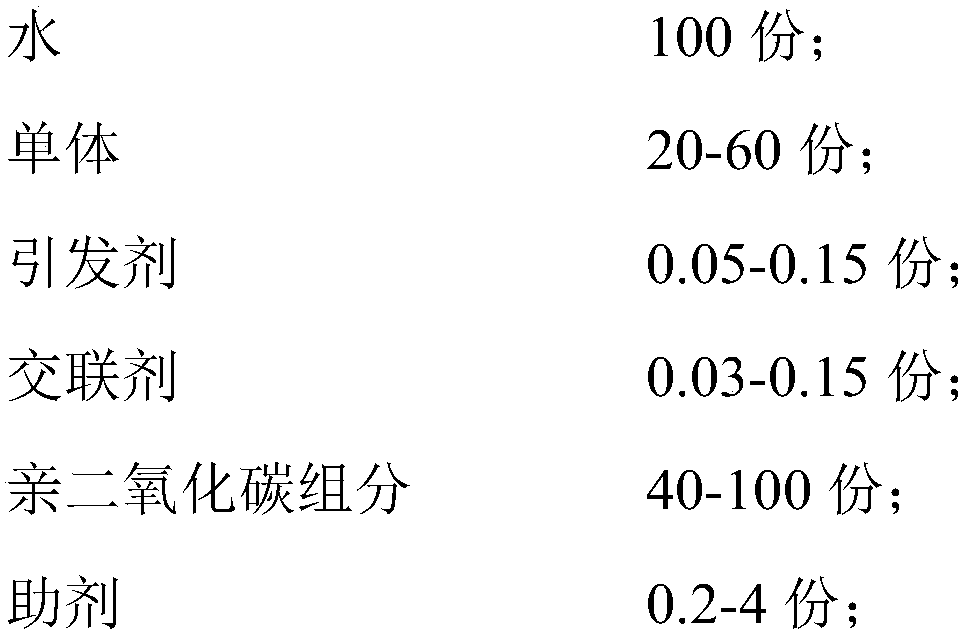

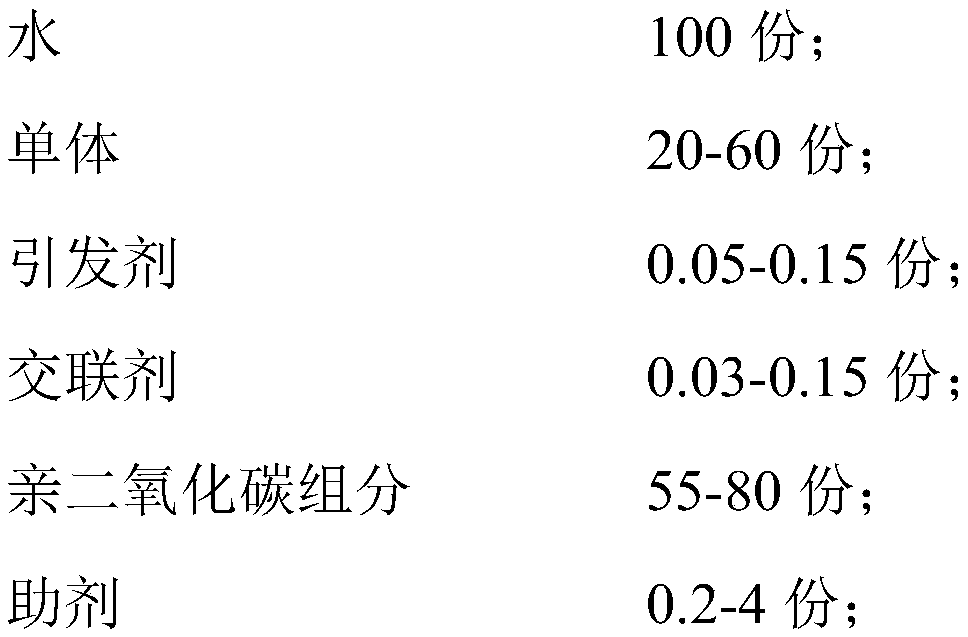

Method used

Image

Examples

Embodiment 1

[0037] Add 100g of water to a 250mL reaction vessel, add 30g of acrylamide, 3g of acrylic acid, 2g of 2-acrylamido-methylpropanesulfonic acid, 0.1g of N,N-methylenebisacrylamide, and sodium hydroxide under stirring conditions 0.4g, 0.2g of ammonia water to dissolve; then add 60g of natural rubber latex, stir until it is evenly dispersed; then add 1g of 5% ammonium persulfate aqueous solution, 1g of 5% sodium bisulfite aqueous solution, and stir evenly; Afterwards, the reaction vessel was sealed, put into a constant temperature oven at 50° C. for polymerization reaction for 5 hours, and the obtained rubber blocks were cut into small pieces, vacuum dried, and pulverized to obtain material A.

Embodiment 2

[0039] Add 100g of water into a 250mL reaction vessel, add 35g of acrylamide, 3g of acrylic acid, 0.08g of N,N-methylenebisacrylamide, 0.9g of sodium carbonate, and 0.3g of ammonia water under stirring conditions to dissolve it; then add natural Latex 80g, stir until it is uniformly dispersed; then add 1.2g of 5% ammonium persulfate aqueous solution and 1.2g of 5% sodium bisulfite aqueous solution, and stir evenly; airtight the reaction vessel after deoxygenating with nitrogen gas, and put it in a constant temperature oven at 40°C The medium polymerization reaction was carried out for 6 hours, and the obtained rubber block was cut into small pieces, dried in vacuum and pulverized to obtain material B.

Embodiment 3

[0041] Add 100g of water into a 250mL reaction vessel, add 35g of acrylamide, 3g of acrylic acid, 0.08g of N,N-methylenebisacrylamide, 0.9g of sodium carbonate, and 0.3g of ammonia water under stirring conditions to dissolve it; then add natural Latex 55g, stir until it is uniformly dispersed; then add 1.2g of 5% ammonium persulfate aqueous solution and 1.2g of 5% sodium bisulfite aqueous solution, and stir evenly; airtight the reaction vessel after deoxygenation with nitrogen gas, and put it in a constant temperature oven at 30°C After 7 hours of medium polymerization, the obtained rubber block was cut into small pieces, dried in vacuum and crushed to obtain material C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com