Purifying treatment technology of coke wet quenching steam

A purification treatment and coke quenching technology, which is applied in coke cooling, coke oven, steam condensation, etc., can solve the problems of polluting the environment and lack of mature technology for wet coke quenching steam purification treatment, and achieves simple operation, low investment cost and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

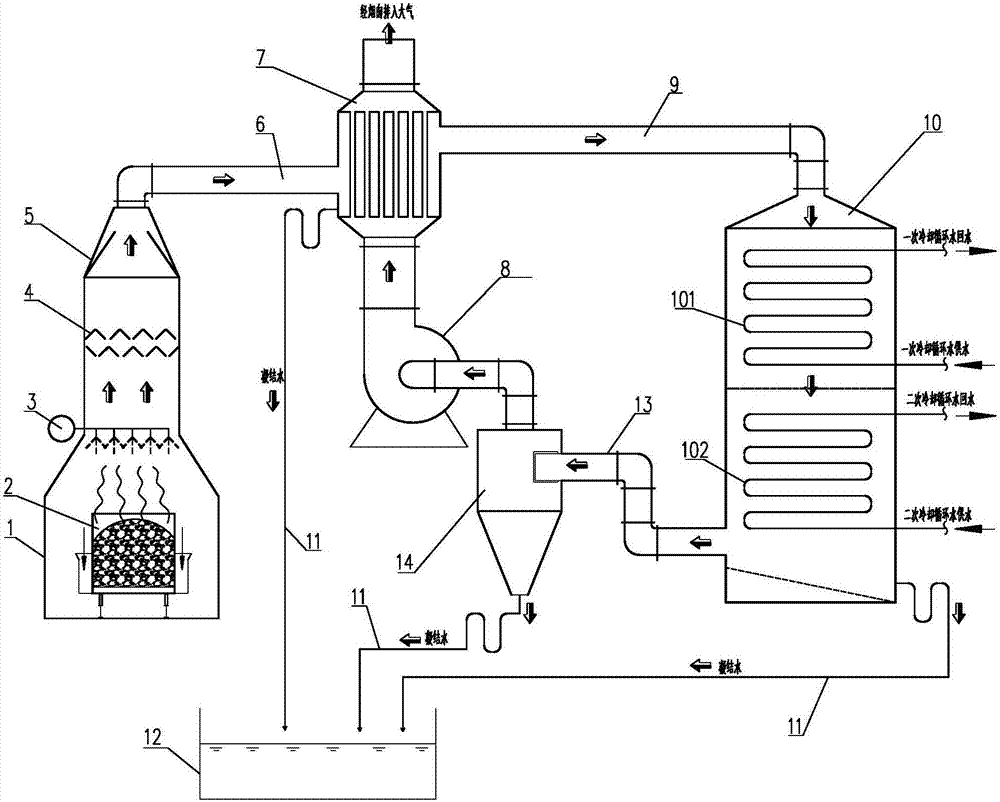

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] like figure 1 As shown, a purification treatment process for wet coke quenching steam according to the present invention, before the wet coke quenching system starts to work, first start the washing and cooling device 3, and form a water mist layer above the coke quenching tank 2 in the wet coke quenching tower 1 , a large amount of quenched fugitives produced during coke quenching rise sharply under the action of thermal buoyancy, and are cooled when passing through the water mist layer, forming condensed droplets with dust particles as the core, which continue to rise with the steam; that is, in the process , a part of the particle dust in the steam is washed down; the rising speed of the steam after washing and cooling in the wet quenching tower 1 has decreased, and when passing through the baffle dust removal device 4, the condensed liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com