Determination method of pasteurization retention time of high-quality milk

A technology of pasteurization and time measurement, which is applied in the direction of material resistance, etc., can solve problems such as loss and loss of nutrients in fresh milk, and achieve the effects of improving control accuracy, stable and reliable equipment support, and reliable and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

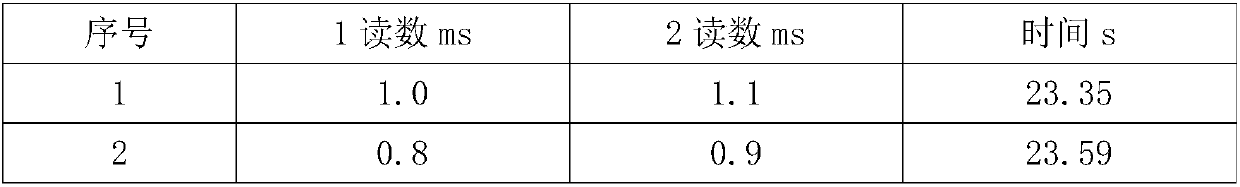

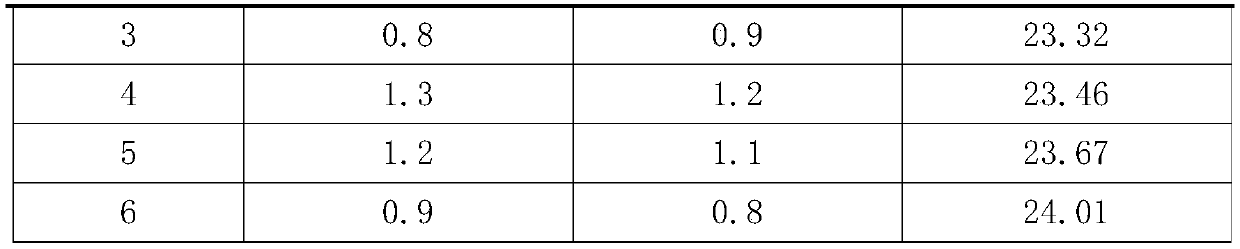

[0038] Insulated pipe retention time test

[0039]Use soft water (to remove most of the ions, reduce the conductivity of pure water, and improve the measurement accuracy), the equipment is running normally, the water temperature is 24°C-26°C, the homogenization pressure is 19Mpa, and the reflux cycle is used for testing when the sterilizer is not heating up. Put 50ml of 7% and 30% sodium chloride solution into the insulation tube quickly through the needle tube. When the conductivity of No. 1 and No. 2 starts to fluctuate, use a stopwatch to calculate the time. There is no fluctuation, because 50ml of 30% concentration sodium chloride solution is used, before the needle tube is quickly injected into the insulation tube, when the conductivity of No. 1 and No. 2 begins to fluctuate, the time is calculated with a stopwatch. as follows:

[0040] Table 1: The first conductivity change record

[0041]

[0042]

[0043] These 6 sets of data are relatively stable data. Befor...

Embodiment 2

[0045] Insulated pipe retention time test

[0046] The test process is the same as the first test. After adjusting the minimum display value of the conductivity meter to 0.01, the test is performed continuously for 6 times. The specific data are as follows:

[0047] Table 2: The second conductivity change record

[0048] serial number

[0049] It can be seen from the data that the shortest holding time is 24.09 seconds, the longest holding time is 24.41 seconds, and the average holding time is 24.35 seconds. In combination with the test results of Example 1, it can be concluded that because of the starting point of the process design of the Tetra Pak sterilizer, its insulation pipe is longer than that of general pasteurization; in addition, because the displayed flow rate is about 9.1 tons, the low flow rate will also affect the holding time. had an impact. Therefore, Tetra Pak engineers are required to arrive at the site, adjust the flow rate to the rated flow ra...

Embodiment 3

[0051] Insulated pipe retention time test

[0052] The test process and specific values, soft water 10.2 tons, homogeneous pressure 19Mpa, sterilization temperature 85±2°C, disconnect the degassing tank, and adjust the flow rate to the rated flow rate by the engineer. The specific values are as follows:

[0053] Table 3: The third conductivity change record

[0054] serial number

[0055] From the perspective of test time, the soft water test has a minimum holding time of 18.78 seconds, a longest holding time of 19.25 seconds, an average holding time of 19.07 seconds, a maximum deviation of 0.33 seconds, and no negative deviation. Note: The theoretical holding time is calculated based on the 0.8 insurance factor provided by Tetra Pak engineers, 15 seconds / 0.8 = 18.75 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com