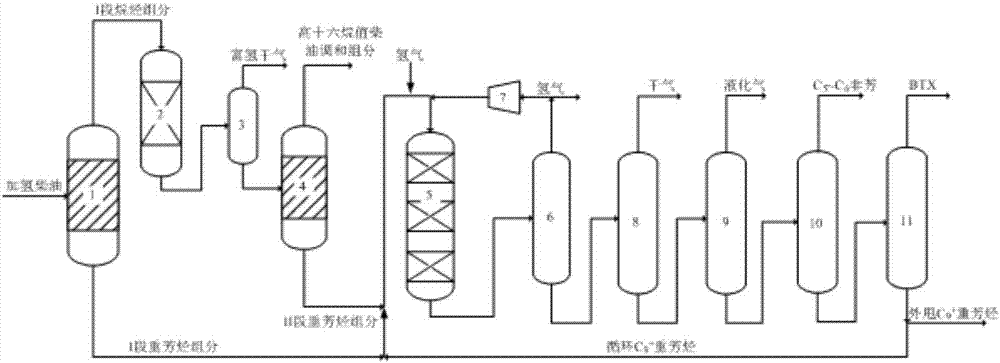

Combined technological method for maximum production of light aromatic hydrocarbon from hydrogenated diesel oil

A technology of light aromatics and hydrogen diesel, which is applied in the field of hydrogenation diesel to prepare light aromatics, can solve the problems of poor adaptability of raw materials, high yield of gasoline and diesel, low yield of aromatics, etc., and achieve strong adaptability of raw materials and high purity of products , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The hydrogenated straight-run diesel oil from a refinery was used as the raw material, and the composition of the raw material is shown in Table 1.

[0036] Both the first-stage adsorption and separation device and the second-stage adsorption and separation device are filled with Cu / 13X molecular sieve catalyst (Cu loading is 4wt%). The reaction conditions of the two adsorption and separation devices are: temperature 120 ° C, pressure 2.0 MPa, mass space velocity 1.5 h -1 .

[0037] The cycloalkane dehydrogenation catalyst adopts Pt / SiO 2 Catalyst (Pt loading is 0.3wt%), reaction conditions: reaction temperature 420°C, pressure 2.0MPa, mass space velocity 1.5h -1 Under the condition of , the cycloalkane dehydrogenation reaction occurs, and the cycloalkane dehydrogenation product rich in aromatics is obtained.

[0038] Heavy aromatics lightening catalysts are Pt-Ni / β (Pt loading is 0.3wt%, Ni loading is 5wt%), non-aromatic cracking catalyst Ni-Mg / ZSM-5 (Ni loading is 4...

Embodiment 2

[0041] The hydrogenated catalytic diesel from a refinery was used as the raw material, and the composition of the raw material is shown in Table 1. All other conditions are the same as in Example 1, the yields of each product are shown in Table 2, and the composition of the diesel product obtained is shown in Table 3.

Embodiment 3

[0043] Hydrogenated straight-run diesel, hydrogenated catalytic diesel, hydrogenated DCC diesel, and hydrocoked diesel blended diesel from a refinery were used as raw materials. The composition of the raw materials is shown in Table 1. All other conditions are the same as in Example 1, the yields of each product are shown in Table 2, and the composition of the diesel product obtained is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com