Ultrasonic preparation method of soybean protein-polysaccharides complex as well as application of functional food

A soybean protein and complex technology, which is applied in the field of protein-polysaccharide complex preparation, can solve the problems of poor coagulation effect and low embedding efficiency of bioactive components, and achieve long release time, good stability and high loading rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

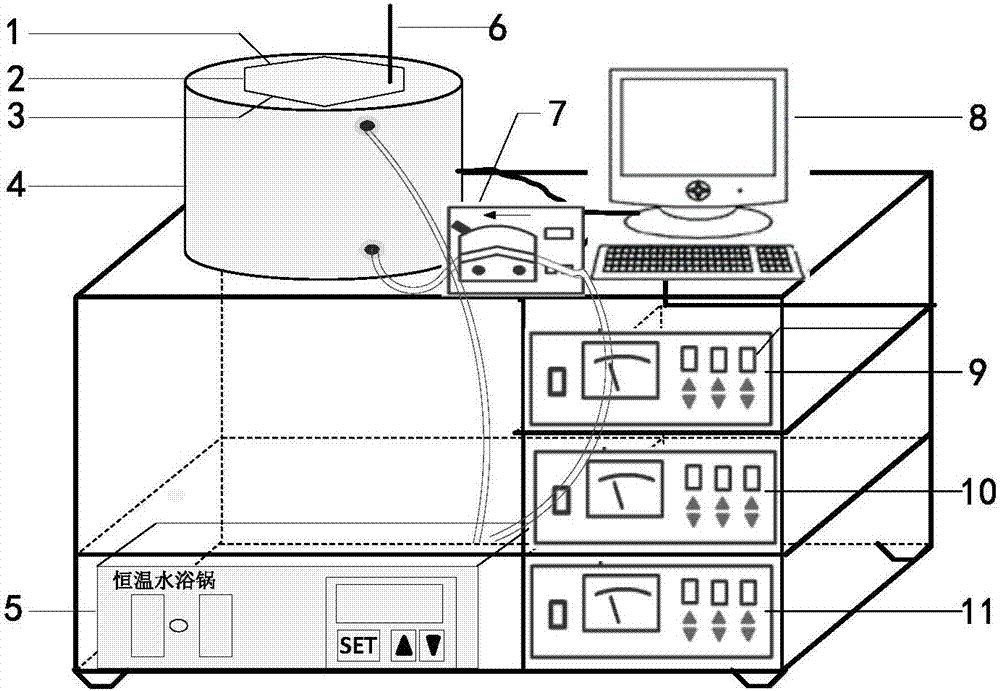

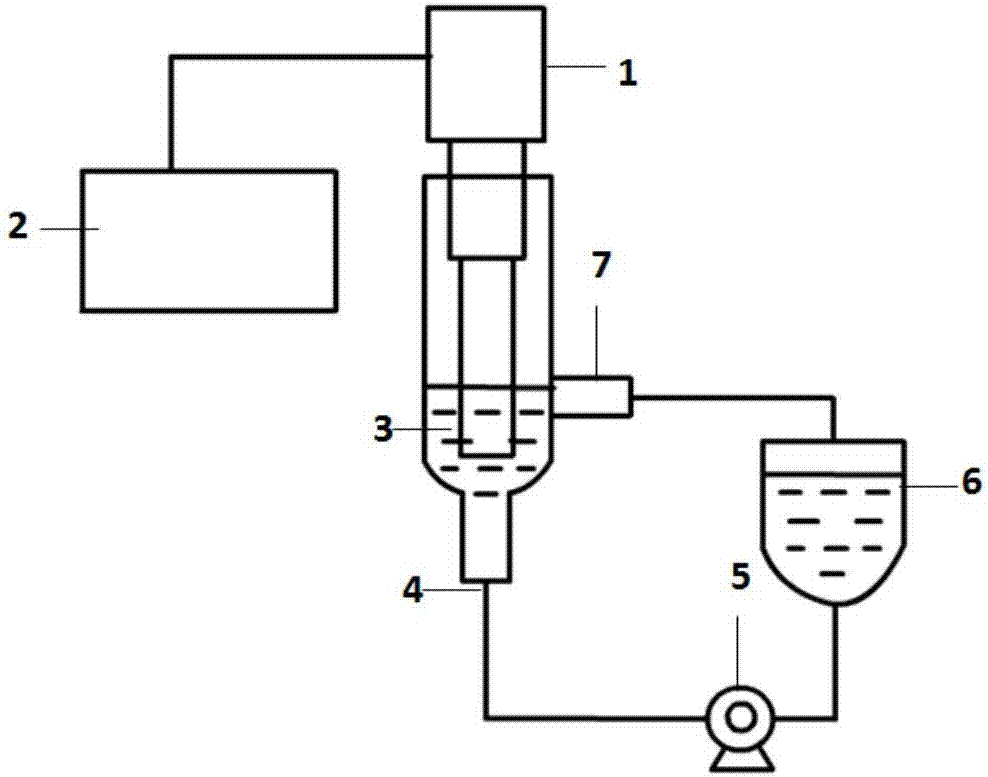

Method used

Image

Examples

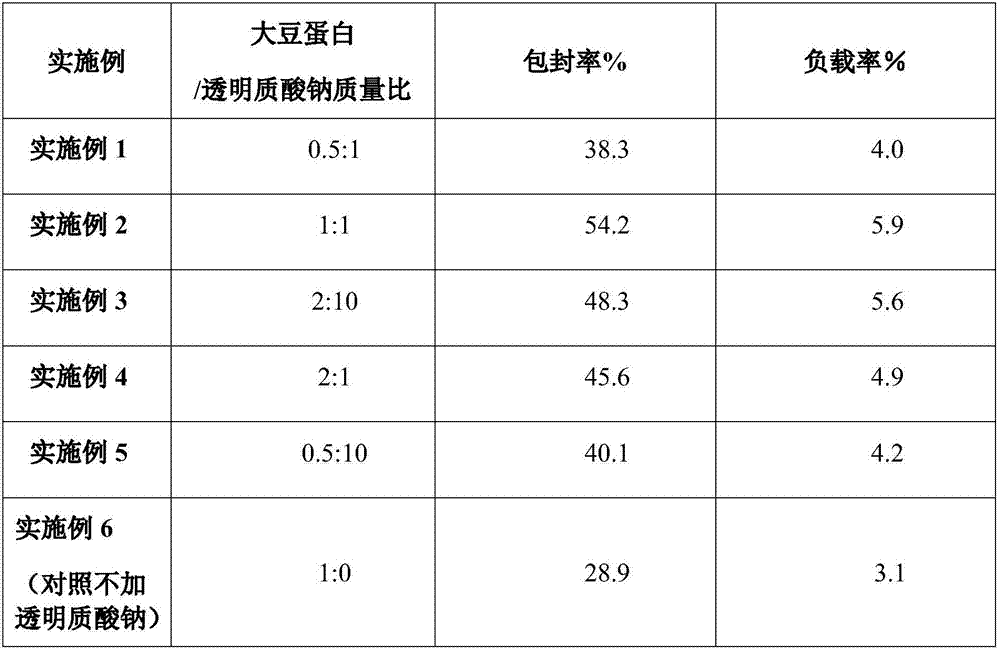

Embodiment 1-6

[0063] Embodiment 1-6 (do not add ultrasonic)

[0064] The preparation method of soybean protein-sodium hyaluronate complex loaded lutein is carried out according to the following steps:

[0065] (1) Dissolve soybean protein in distilled water, stir magnetically for 2 hours at room temperature, and then place it in a 4°C environment overnight; then centrifuge the soybean protein dispersion at 10,000rpm at 4°C for 30min to obtain a soybean protein concentration of ( 0.5-2) mg / mL dispersion;

[0066] (2) Dissolve sodium hyaluronate into the aqueous solution, and magnetically stir until completely dissolved; obtain a sodium hyaluronate solution with a concentration of (1-10) mg / mL;

[0067] (3) Step (2) sodium hyaluronate solution is added dropwise to step (1) soybean protein solution in a ratio of 1:1 by volume, so that the mass ratio of soybean protein and sodium hyaluronate is shown in Table 1, and then Adjust the pH=5 of the mixed solution.

[0068] (4) The absolute ethano...

Embodiment 7-10

[0078] Embodiment 7-10 (add multi-mode frequency ultrasonic treatment)

[0079] The preparation method of soybean protein-sodium hyaluronate complex loaded lutein is carried out according to the following steps:

[0080] (1) Dissolve soybean protein in distilled water, stir magnetically for 2 hours at room temperature, and then let it stand at 4°C overnight; then centrifuge the soybean protein dispersion at 10,000 rpm at 4°C for 30 minutes to obtain a soybean protein concentration of 0.5 mg / mL dispersion;

[0081] (2) Sodium hyaluronate is dissolved in the aqueous solution, and magnetically stirred until completely dissolved; a sodium hyaluronate solution having a concentration of 1 mg / mL is obtained;

[0082] (3) The sodium hyaluronate solution in step (2) is added dropwise to the soybean protein solution in step (1) at a volume ratio of 1:1, so that the mass ratio of soybean protein to sodium hyaluronate is 0.5:1, Then adjust the pH=5 of the mixed solution.

[0083](4) Th...

Embodiment 11-12

[0090] Embodiment 11-12 (add countercurrent ultrasonic treatment)

[0091] The preparation method of soybean protein-sodium hyaluronate complex loaded lutein is carried out according to the following steps:

[0092] (1) Dissolve soybean protein in distilled water, stir magnetically for 2 hours at room temperature, and then let it stand at 4°C overnight; then centrifuge the soybean protein dispersion at 10,000 rpm at 4°C for 30 minutes to obtain a soybean protein concentration of 0.5 mg / mL dispersion;

[0093] (2) Sodium hyaluronate is dissolved in the aqueous solution, and magnetically stirred until completely dissolved; a sodium hyaluronate solution having a concentration of 1 mg / mL is obtained;

[0094] (3) The sodium hyaluronate solution in step (2) is added dropwise to the soybean protein solution in step (1) at a volume ratio of 1:1, so that the mass ratio of soybean protein to sodium hyaluronate is 0.5:1, Then adjust the pH=5 of the mixed solution.

[0095] (4) The ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com