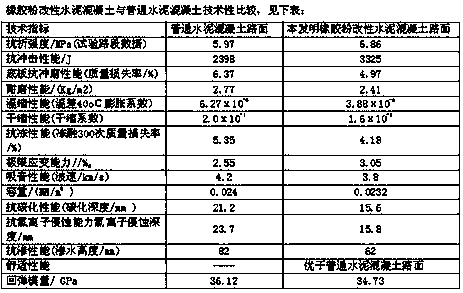

A kind of rubber powder modified cement concrete pavement and its manufacturing method

A technology of cement concrete and rubber powder, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of large load, temperature dry and wet deformation, high rigidity of concrete slab, and unsuitable for large settlement, etc. The effect of reducing black pollution, reducing engineering cost, improving high temperature micro-expansion and residual deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A rubber powder modified cement concrete pavement, the cement concrete pavement comprises the following raw materials in parts by weight:

[0056] Rubber powder 25kg / m³ 425 cement 300kg / m³

[0057] River sand 550kg / m³ gravel 1130kg / m³

[0058] Water 135kg / m³ Water reducer 5.5kg / m³

[0059] Phthalate coupling agent 3kg / m³ Rubber latex 2kg / m³

[0060] Hydrophobic modified cellulose 3kg / m³ lignin 15kg / m³ (recycled by banana stalks, see the content of the invention)

[0061] Granulated blast furnace slag powder 110kg / m³.

[0062] The fineness of the rubber powder is 20 mesh.

[0063] The fineness of the granulated blast furnace slag powder is 200 mesh.

[0064] The fineness modulus of the river sand is 2.2-3.5.

[0065] The grain size of the gravel is 5-37.5mm.

[0066] The manufacturing method comprises the following steps:

[0067] (1) Production and selection of rubber powder; rubber powder (granules) comes from waste tires, and waste tires can be divided into tw...

Embodiment 2

[0071] A rubber powder modified cement concrete pavement, the cement concrete pavement comprises the following raw materials in parts by weight:

[0072] Rubber powder 30kg / m³ 425 cement 330kg / m³

[0073] River sand 590kg / m³ gravel 1180kg / m³

[0074] Water 145kg / m³ Water reducer 6.5kg / m³

[0075] Phthalate coupling agent 4kg / m³ Rubber latex 3kg / m³

[0076] Hydrophobic modified cellulose 4kg / m³ Lignin 20kg / m³ (extracted by papermaking black liquor, see the content of the invention for the method)

[0077] Granulated blast furnace slag powder 100kg / m³.

[0078] The fineness of the rubber powder is 60 mesh.

[0079] The fineness of the granulated blast furnace slag powder is 280 mesh.

[0080] The fineness modulus of the river sand is 2.2-3.5.

[0081] The grain size of the gravel is 5-37.5mm.

[0082] The manufacturing method comprises the following steps:

[0083] (1) Production and selection of rubber powder; rubber powder (granules) comes from waste tires, and waste t...

Embodiment 3

[0087] A rubber powder modified cement concrete pavement, the cement concrete pavement comprises the following raw materials in parts by weight:

[0088] Rubber powder 27kg / m³ 425 cement 315kg / m³

[0089] River sand 570kg / m³ gravel 1110kg / m³

[0090] Water 150kg / m³ Water reducer 6.2kg / m³

[0091] Phthalate coupling agent 3.5kg / m³ Rubber latex 2.5kg / m³

[0092] Hydrophobic modified cellulose 3.5kg / m³ Lignin 17.5kg / m³ (extracted by papermaking black liquor, see the content of the invention for the method)

[0093] Granulated blast furnace slag powder 95kg / m³.

[0094] The fineness of the rubber powder is 40 mesh.

[0095] The fineness of the granulated blast furnace slag powder is 240 mesh.

[0096] The fineness modulus of the river sand is 2.2-3.5.

[0097] The grain size of the gravel is 5-37.5mm.

[0098] The manufacturing method comprises the following steps:

[0099] (1) Production and selection of rubber powder; rubber powder (granules) comes from waste tires, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com