Glass composition and preparing method and application thereof

A technology of glass composition and dosage, which is applied in the field of glass composition and its preparation, can solve the problems of no breakthroughs, deficiencies, damage resistance of touch screen cover glass, etc., and achieve high compressive stress and deep strengthening depth , the effect of high Vickers hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The third aspect of the present disclosure provides the glass composition prepared by the above-mentioned preparation method; the glass composition is suitable for processing, and the present disclosure has no special limitation on the processing method, which can be various commonly used in this field. Various processing methods, such as slicing, grinding, polishing and chemical strengthening.

[0041] The fourth aspect of the present disclosure provides the application of the above-mentioned glass composition in the preparation of a touch screen and / or a solar cell.

[0042] According to the fourth aspect of the present disclosure, when the glass composition is used in the preparation of touch screens and / or solar cells, chemical strengthening is required to improve mechanical properties. The chemical strengthening method can be various chemical strengthening methods routinely used by those skilled in the art, and the present disclosure has no particular limitation on...

Embodiment

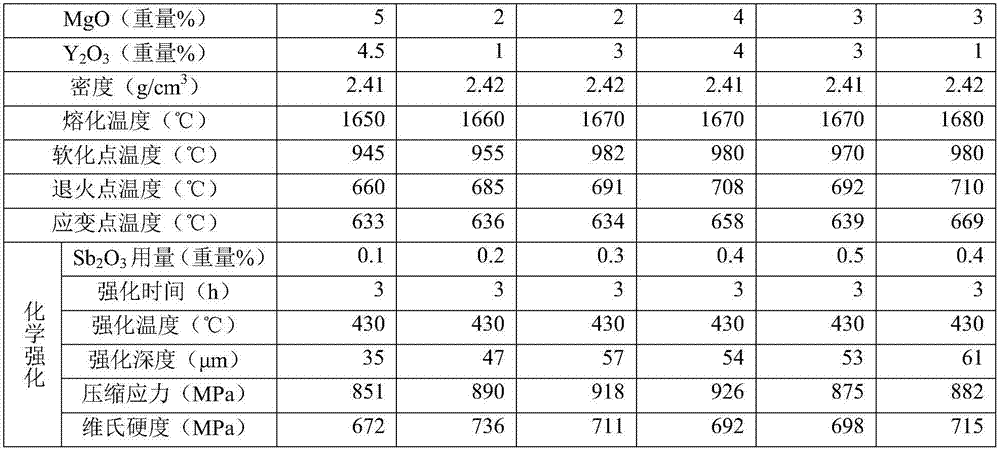

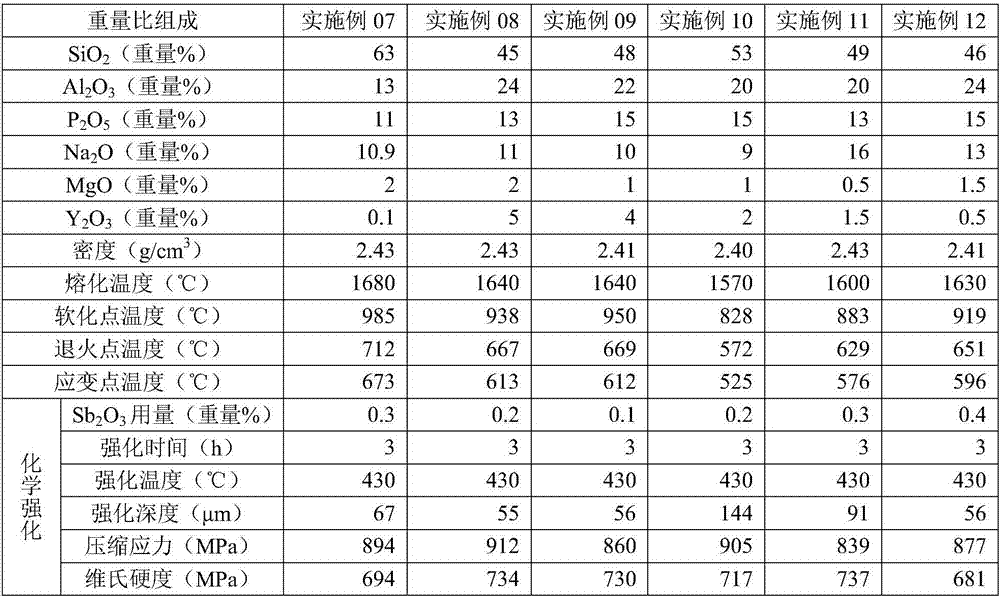

[0047] Table 1 lists the glass compositions described in the present disclosure manufactured through research and development experiments and their physical properties (density, melting temperature, softening point temperature, annealing point temperature, strain point temperature) and mechanical properties after strengthening (compressive stress, strengthening depth and Vickers hardness). The preparation steps include: mixing the glass composition according to the proportion, each weight is about 2kg. Mix the mixture evenly, put it into a platinum-rhodium crucible and melt for 5-12h, the melting temperature is as shown in Table 1, use a platinum stirring rod to stir and homogenize to obtain a glass composition melt; pour the glass composition melt into a mold Pouring molding at room temperature, and after cooling to room temperature, the cast glass composition workpiece was obtained; the glass composition workpiece was annealed for 2 hours, and the annealing temperature was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com