High-strength antistatic polyethylene film as well as preparation method and application thereof

A technology of polyethylene film and low-density polyethylene, which is applied in the field of high-strength antistatic polyethylene film and its preparation, can solve the problems of large film thickness, high cost, and damage to precision electronic components, so as to improve electrical conductivity, anti-static Long-lasting electrostatic properties and improved antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

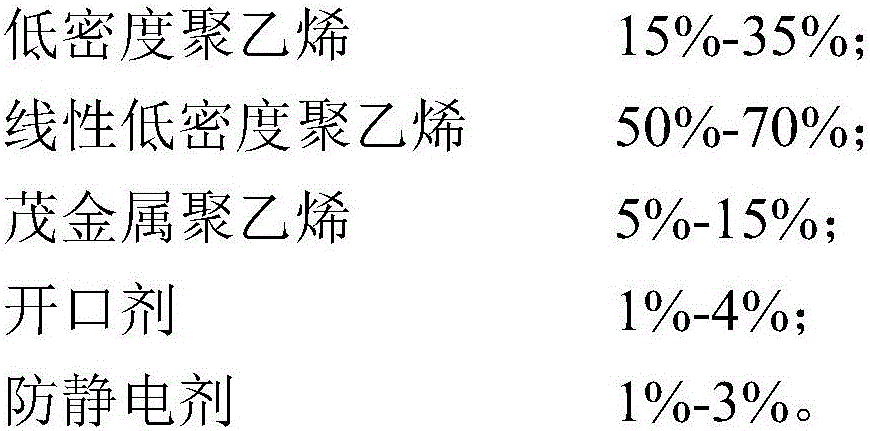

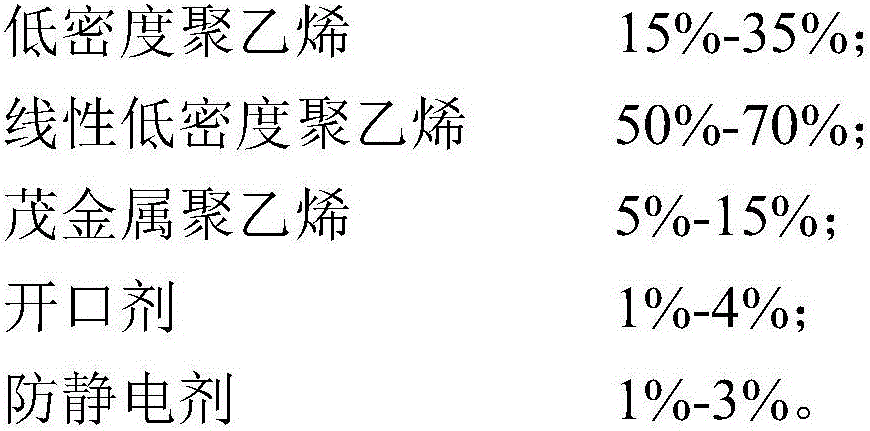

Method used

Image

Examples

Embodiment 1

[0035] a. 15kg melt index is 0.27g / 10min, density is 0.918g / cm 3 Low-density polyethylene, 65kg melt index is 0.7g / 10min, density is 0.95g / cm 3 Linear low density polyethylene, 15kg melt index is 0.5g / 10min, density is 0.910g / cm 3 The metallocene polyethylene, the mixture of 1kg oleic acid amide and 2kg silicon dioxide and 2kg antistatic agent are put into the mixer, and then stirred at a speed of 1800rpm for 15min to obtain the mixed masterbatch, which is sucked into the hopper with a suction machine Evenly feed the film blowing machine, the temperature setting of the film blowing machine is: the first zone is 130°C, the second zone is 135°C, the third zone and the fourth zone are 140°C, the filter screen is 140°C, after plasticizing, it will pass through 80°C Purpose Stainless steel gauze filters impurities, and then is extruded by a die head at a temperature of 135°C to obtain a high-strength anti-static polyethylene film, which is then blown into a cylindrical shape by a ...

Embodiment 2

[0041] a. 25kg melt index is 0.3g / 10min, density is 0.920g / cm 3 Low-density polyethylene, 60kg melt index is 0.7g / 10min, density is 0.96g / cm 3 Linear low density polyethylene, 10kg melt index is 0.5g / 10min, density is 0.915g / cm 3 The metallocene polyethylene, the mixture of 0.5kg diatomite and 1.5kg silicon dioxide and 3kg antistatic agent are put into the mixer, and then stirred at the speed of 2000rpm for 20min to obtain the mixed masterbatch, which is mixed with a suction machine The suction hopper feeds the blown film machine evenly. The temperature of the blown film machine is set as follows: the first zone is 132°C, the second zone is 137°C, the third zone and the fourth zone are 142°C, and the filter screen is 142°C. Filter impurities through 80-mesh stainless steel gauze, and then extruded by die head, the temperature of die head is 140 ℃, to obtain high-strength anti-static polyethylene film, then blown into a cylindrical shape through a hair dryer, and finally pulle...

Embodiment 3

[0047] a. 35kg melt index is 0.5g / 10min, density is 0.925g / cm 3 Low-density polyethylene, 54kg melt index is 0.7g / 10min, density is 0.97g / cm 3 Linear low density polyethylene, 5kg melt index is 0.75g / 10min, density is 0.940g / cm 3 The metallocene polyethylene, 4kg oleic acid amide and 2kg antistatic agent are put into the mixer, and then stirred at a speed of 2000rpm for 25min to obtain the mixed masterbatch, and the mixed masterbatch is sucked into the hopper by a suction machine and evenly fed into the film blowing machine. The temperature of the film blowing machine is set as follows: the first zone is 135°C, the second zone is 140°C, the third zone and the fourth zone are 145°C, the filter screen is 145°C, after plasticizing, it passes through 80-mesh stainless steel gauze to filter impurities. Then it is extruded by a die with a die temperature of 145°C to obtain a high-strength anti-static polyethylene film, which is then blown into a tube by a hair dryer, and finally wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com