Device and method for treating leather processing wastewater

A technology for processing waste water and treatment equipment, which is applied in the direction of animal processing waste water treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve problems such as difficult discharge of water to meet standards, and achieve the effects of simple operation, thorough treatment, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

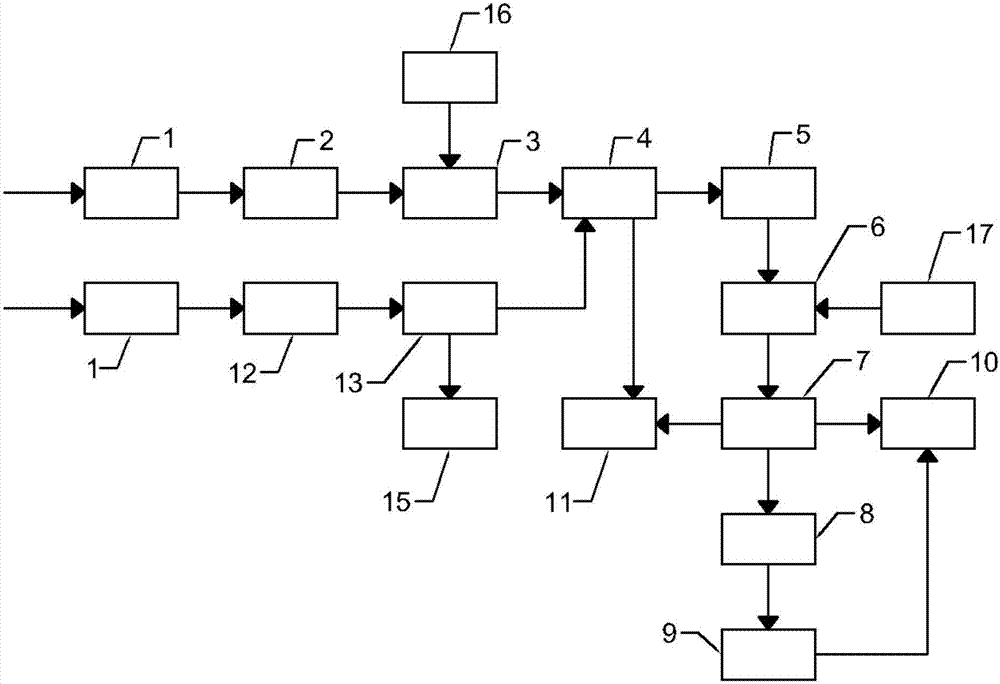

[0029] see figure 1 , a fur processing wastewater treatment device, comprising grid well 1, dyeing water collection well 2, dyeing reaction tank 3, primary sedimentation tank 4, hydrolysis tank 5, oxidation tank 6, secondary sedimentation tank 7, secondary reaction tank 8, final Settling pond 9, discharge well 10, sludge thickening tank 11, chrome liquid water collection well 12, chrome liquid reaction tank 13 and chrome mud concentration pond 15, described dyeing water collection well 2 is connected to dyeing waste water output end, chrome liquid water collection well 12 Connected to the output end of chromium-containing waste water, between the dyeing waste water output end and the dyeing water collection well 2, between the chromium waste water output end and the chromium liquid water collection well 12, a grid well 1 is arranged, and the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com