Particle classification device and method thereof

A particle classification and particle technology, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve the problem of complex structure of wind eddy current classifier, inconvenient adjustment of cutting particle size, cutting particle size Inconvenient adjustment and other problems to achieve the effect of weakening mutual interference/coercion, reducing pressure drop, and low degree of back mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The particle classification device used in the experiment includes a cyclone separator 2, a sedimentation classifier 6, a coarse / heavy particle group collector 4 and a fine / light particle group collector 5; the top of the cyclone separator 2 cylinder is connected to the tail air outlet pipe through a cone 1, the inlet end does not extend into the cyclone separator 2, the outlet end of the tail air outlet pipe 1 is connected to the fine / light particle group collector 5, and the lower part of the cyclone separator 2 cylinder is provided with a primary air inlet pipe 3. The bottom of the cyclone separator 2 is a cone structure, which is connected to the top of the sedimentation classifier 6; the height-diameter ratio of the sedimentation classifier 6 is 20:1, and the bottom of the sedimentation classifier 6 is connected to the coarse / heavy particle The heavy particle group collector 4 is provided with a secondary air intake pipe 7 .

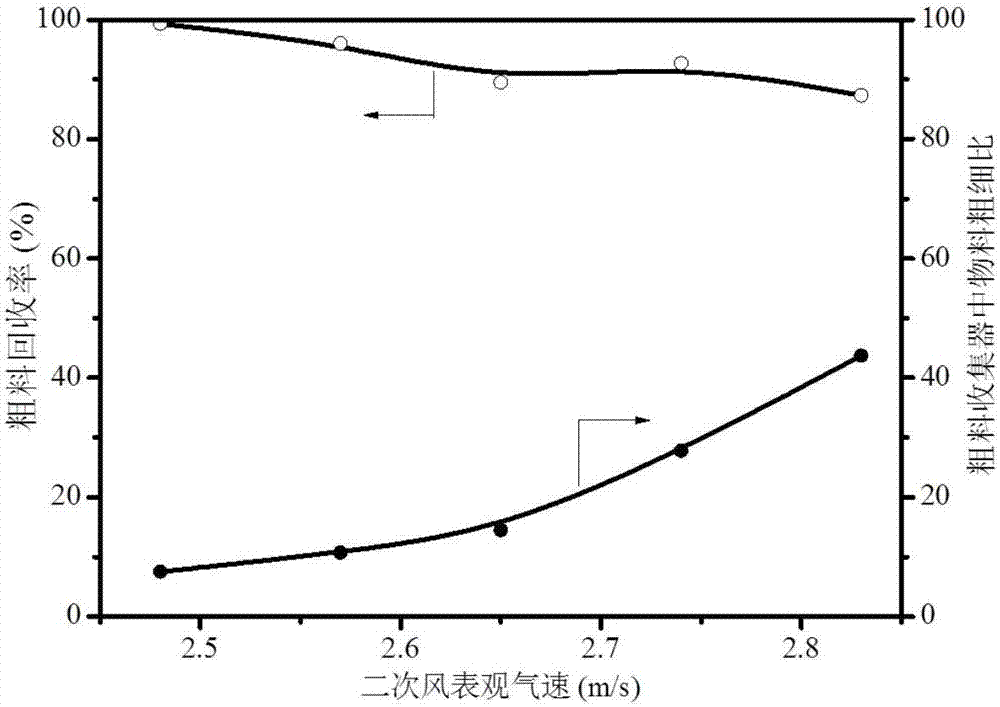

[0026] A mixture of 20-40 mesh and 60-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com