Pipeline steel with sulfate reducing bacterium corrosion resistance performance

A technology for corrosion performance and pipeline steel, applied in the field of pipeline steel, can solve the problem of not taking into account the corrosion resistance of materials such as sulfate-reducing bacteria, achieve excellent resistance to sulfate-reducing bacteria corrosion, and reduce sulfate-reducing bacteria corrosion. effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

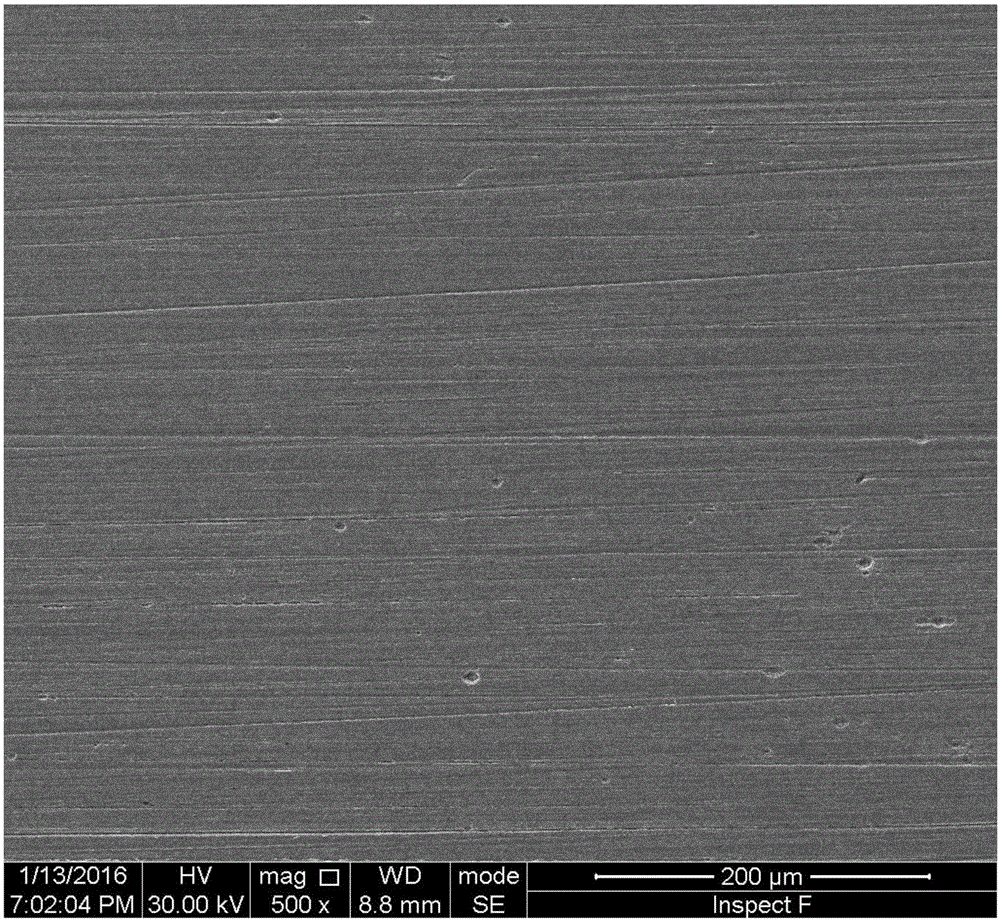

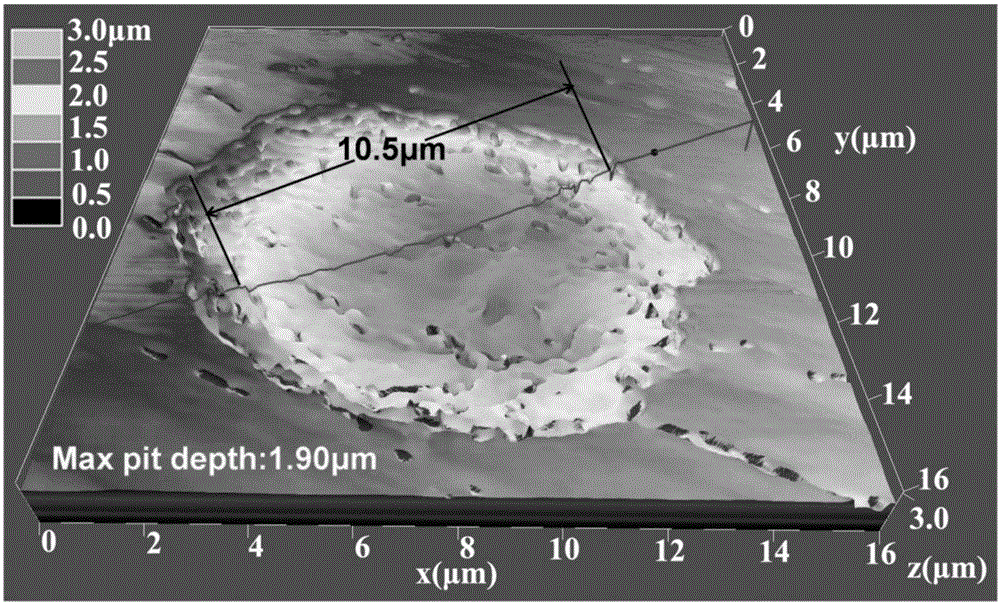

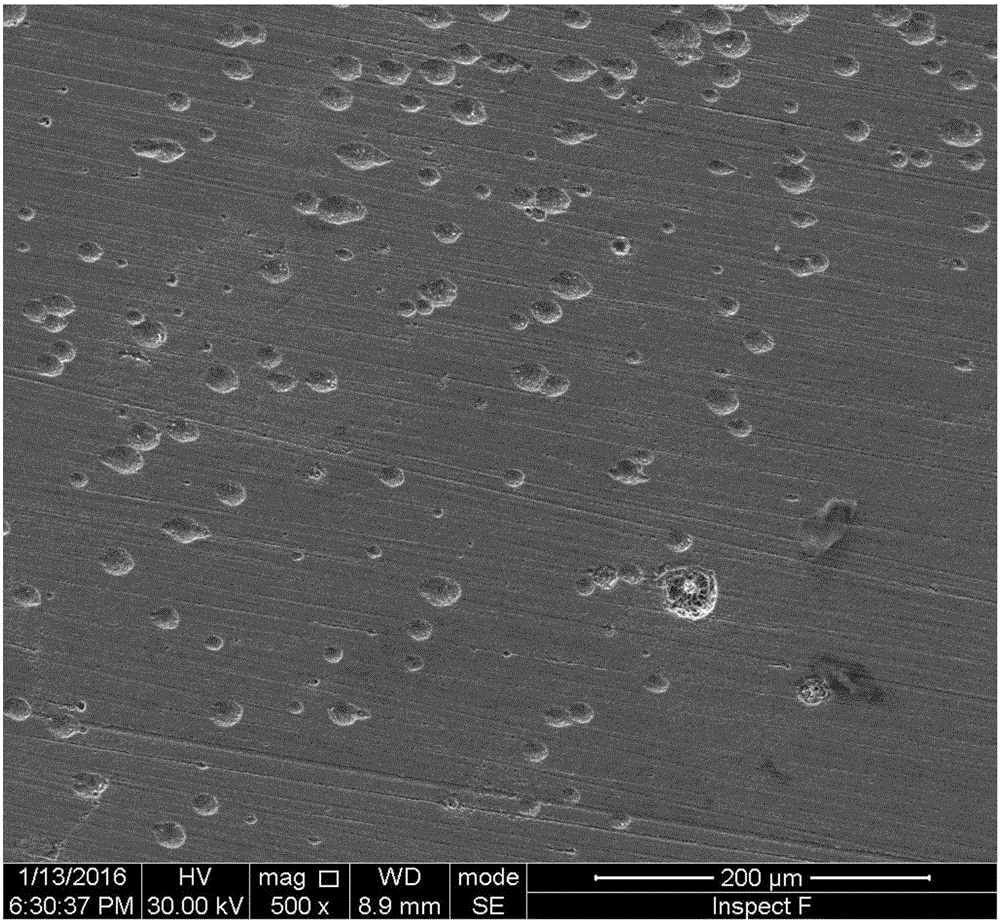

[0020] Example Pipeline steel was smelted and forged in a laboratory-scale vacuum induction furnace, followed by thermomechanically controlled rolling and controlled cooling. The existing commercial pipeline steel was used as a comparative example, and its chemical composition is shown in Table 1.

[0021] The chemical composition of table 1 embodiment and comparative example pipeline steel, (weight percentage, %)

[0022]

[0023]

[0024] All the pipeline steels in the examples adopt the best heat treatment process for copper precipitation: heat preservation at 550° C. for 1 hour, and air cooling. The pipeline steel of the comparative example kept the original rolling state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com