Steel structure with anti-corrosion function and anti-corrosion process thereof

A steel structure, anti-corrosion technology, applied in building components, building structures, building insulation materials, etc., can solve problems such as erosion, loose connections at joints, etc., to achieve strong corrosion resistance, strong adhesion, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

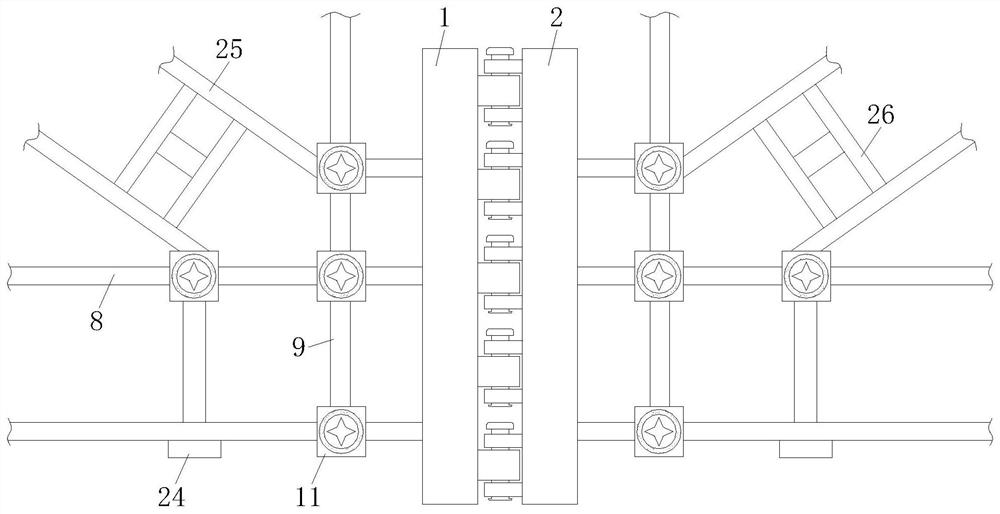

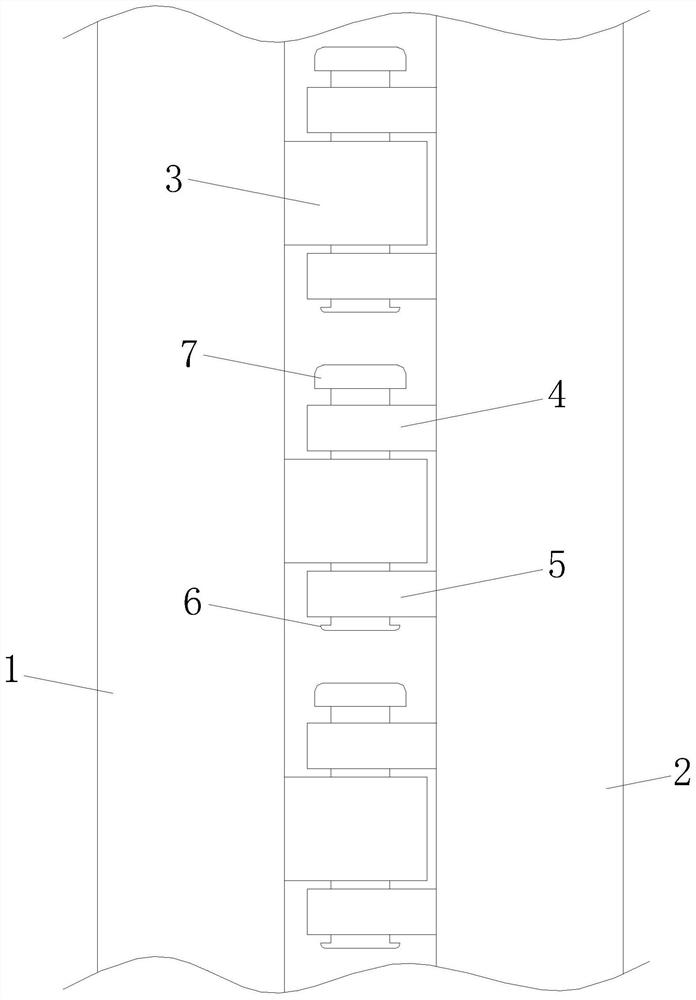

[0038] see Figure 1-5 , a steel structure with anti-corrosion function, comprising a left connector 1, a right connector 2, a transverse frame beam 8 and a longitudinal frame beam 9, the left connector 1 is provided with a lock on the side surface close to the right connector 2 block 3, the right connector 2 is provided with an upper lock hole 4 and a lower lock hole 5 on the side surface close to the left connector 1, the lock block 3 is located between the upper lock hole 4 and the lower lock hole 5, the The lock block 3, the upper lock hole 4 and the lower lock hole 5 are movably connected together by a fixed rod 6;

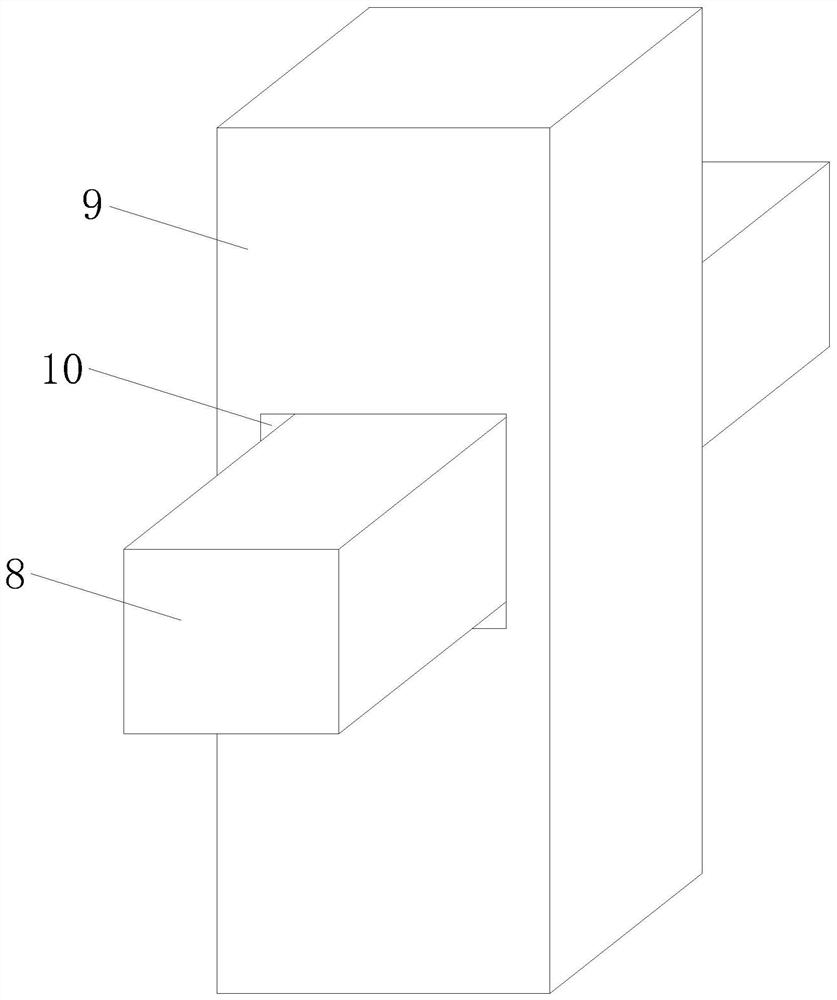

[0039] The surface of the longitudinal frame beam 9 is provided with an assembly hole 10, which is used for assembling and fixing between the transverse frame beam 8 and the longitudinal frame beam 9. A protective cover 11 is provided outside the assembly hole 10, and the protective cover 11 One side surface is provided with a mounting hole 14, and the insid...

Embodiment 2

[0047] A steel structure with anti-corrosion function, including a left connector 1, a right connector 2, a transverse frame beam 8 and a longitudinal frame beam 9, the left connector 1 is provided with a locking block on a side surface close to the right connector 2 3. An upper lock hole 4 and a lower lock hole 5 are provided on the side surface of the right connector 2 close to the left connector 1. The lock block 3 is located between the upper lock hole 4 and the lower lock hole 5. The lock The block 3, the upper lock hole 4 and the lower lock hole 5 are movably connected together by a fixed rod 6;

[0048] The surface of the longitudinal frame beam 9 is provided with an assembly hole 10, which is used for assembling and fixing between the transverse frame beam 8 and the longitudinal frame beam 9. A protective cover 11 is provided outside the assembly hole 10, and the protective cover 11 One side surface is provided with a mounting hole 14, and the inside of the mounting ho...

Embodiment 3

[0057] see Figure 8 and Figure 9 Carrying out anti-corrosion treatment to any steel structure with anti-corrosion function described in embodiment one or embodiment two, comprising the following specific steps:

[0058] S1, derusting and decontaminating the surface of the steel structure;

[0059] S2, spray epoxy zinc-rich paint 20 on the surface of the steel structure, and carry out air-drying and curing treatment after spraying;

[0060] S3, spray epoxy cloud iron paint 21 on the surface of the steel structure, and carry out air-drying curing treatment after spraying;

[0061] S4, spray the chlorinated rubber topcoat 22 on the surface of the steel structure, spray the chlorinated rubber topcoat 22 twice, and carry out air-drying and curing treatment after spraying;

[0062] S5. Use the reinforcing colloid 23 in a liquid state to smear on the surface of the steel structure, and after smearing evenly, dry and solidify it;

[0063] S6. Complete the anti-corrosion treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com